Why Precision Measurement Is the Backbone of Modern Manufacturing

Every successful manufacturing process depends on one key factor — precision. Whether it produces aircraft components, automotive parts, or electronic enclosures, every millimeter matters. Precision measurement in manufacturing ensures that every product meets exact specifications, performs perfectly, and maintains consistent quality. It’s not just a technical requirement — it’s the foundation of modern manufacturing excellence.

Understanding Precision Measurement in Manufacturing

Precision measurement in manufacturing refers to the use of advanced tools, instruments, and techniques to check dimensions, alignment, and tolerance levels of parts and assemblies. It helps manufacturers confirm that every product is made exactly according to the design specifications.

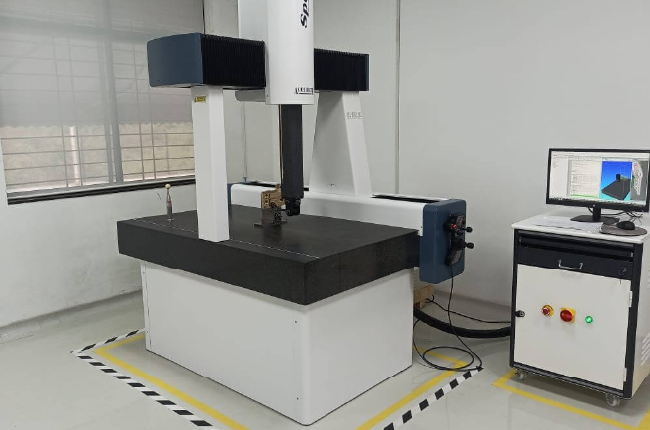

This process involves tools like coordinate measuring machines (CMMs), laser scanners, micrometers, calipers, and optical measuring systems. These tools capture even the smallest variations in dimensions, which is essential for high-performance industries such as aerospace, automotive, energy, and electronics.

When a part is produced with high precision, it ensures better performance, reduces wear and tear, and increases product life. That’s why manufacturers invest heavily in dimensional inspection and precision measurement systems to maintain their quality standards.

Why Precision Measurement Is Important in Modern Manufacturing

Precision measurement is more than a quality check; it’s a guarantee of trust between manufacturers and customers. Let’s explore why it is so critical.

1. Ensures Product Quality and Consistency

One of the most important roles of precision measurement in manufacturing is maintaining product quality. When every component is measured accurately, it ensures that each unit matches the same high standard. This consistency builds confidence in the brand and helps manufacturers meet global compliance standards.

Even a tiny deviation in dimensions can lead to functional failures, especially in industries like aerospace or medical devices. That’s why high-precision measurement systems are used at every stage — from design to final inspection.

2. Reduces Manufacturing Errors and Wastage

Manufacturing errors can be costly, both in time and material. Precision measurement helps detect defects and dimensional variations early in the production process. This early detection prevents defective parts from moving forward, reducing rework and material waste.

By identifying problems at the root level, manufacturers can make quick adjustments, leading to smoother production and improved resource efficiency. This not only saves costs but also supports sustainable manufacturing practices.

3. Improves Assembly and Performance

In modern manufacturing, especially in sectors like automotive and aerospace, products are often made from multiple components that must fit together perfectly. Precision measurement ensures that each part aligns correctly with others, resulting in flawless assembly and smooth operation.

Proper measurement eliminates the risk of vibration, noise, or premature failure. It ensures that the final product performs efficiently and safely under all operating conditions.

4. Supports Advanced Manufacturing Technologies

Technologies like CNC machining, 3D printing, and laser cutting rely heavily on precision measurement. Without accurate measurements, it’s impossible to produce complex designs or maintain tight tolerances.

Precision measurement data also supports digital manufacturing and Industry 4.0, where real-time data and automation improve decision-making and reduce human error. The integration of precise measurement systems with smart manufacturing technologies ensures faster production cycles and higher product accuracy.

5. Enhances Global Competitiveness

For manufacturers serving international markets, precision measurement in manufacturing is a must. Clients across the globe expect products that meet exact specifications and international standards. By investing in accurate measurement systems, manufacturers can confidently compete on quality and reliability.

It not only strengthens brand reputation but also opens opportunities to serve industries that demand zero-tolerance error — like defense, electronics, and renewable energy.

Precision Measurement Tools in Modern Manufacturing

There are several tools and technologies used for precision measurement. Some of the most common ones include:

Coordinate Measuring Machines (CMMs) – Used to measure the geometry of parts and assemblies with extreme accuracy.

Laser Scanning Systems – Capture 3D data quickly and are ideal for complex geometries.

Optical Comparators – Used for comparing the part with a standard template to ensure correct dimensions.

Surface Roughness Testers – Measure the smoothness of surfaces, crucial for high-friction or aesthetic applications.

Micrometers and Calipers – Simple but essential tools for quick, accurate measurements.

Each of these tools plays an important role in ensuring precision throughout the production process.

The Future of Precision Measurement in Manufacturing

Modern manufacturing is evolving fast, and so are measurement technologies. Today’s systems are becoming smarter, faster, and more connected. With the rise of automation, artificial intelligence, and machine learning, precision measurement is no longer just a final step but an integrated part of the entire manufacturing process.

Automated measurement systems now provide real-time feedback to machines, allowing instant corrections during production. This leads to higher accuracy, lower costs, and faster delivery times. As technology continues to advance, the role of precision measurement will only grow stronger.

Conclusion

Precision measurement in manufacturing is not just about numbers; it’s about building trust, reliability, and global competitiveness. It ensures that every component, no matter how small, meets the exact design of intent and functions as expected.

From aerospace to automotive, from electronics to energy, every industry depends on accurate measurements to achieve quality and efficiency. Manufacturers who prioritize precision measurement are the ones shaping the future of modern industry.

At VmakeU, we understand the importance of precision in every project we handle. Our advanced manufacturing solutions are backed by strict measurement and quality control standards to deliver accuracy, performance, and trust.

If you are looking for reliable manufacturing partners who value precision as much as you do, contact VmakeU today. Let’s create excellence together.