What materials should not be cut with a laser cutter

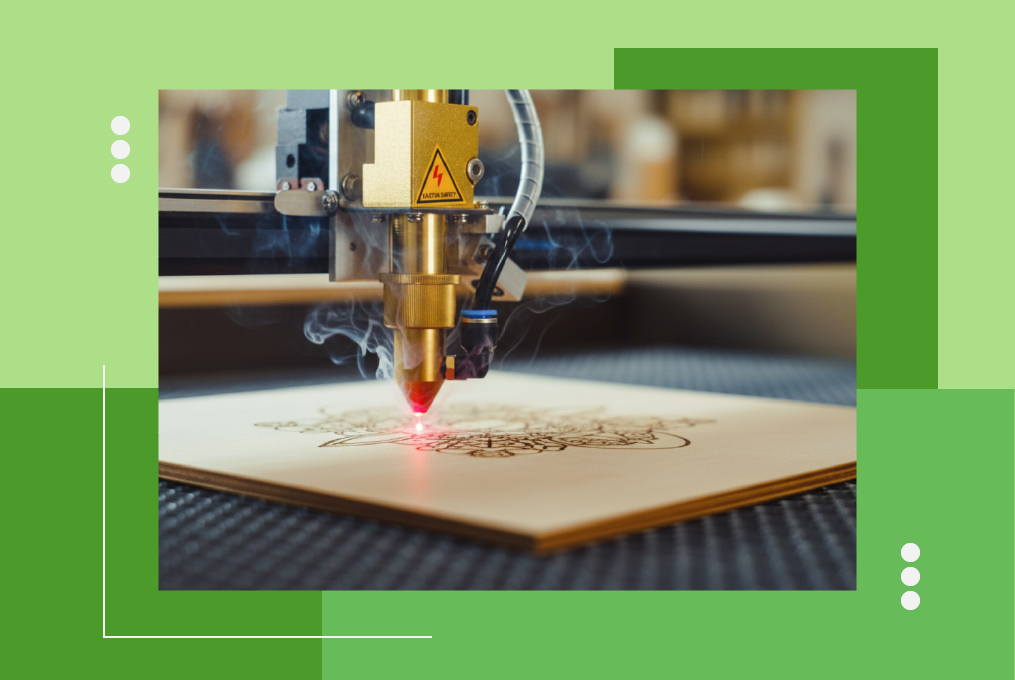

Laser cutters are powerful tools that can cut through many materials with precision. From wood to metal, they’ve become popular in industries like manufacturing, design, and even art. However, not all materials are suitable for laser cutting. Some can be harmful to the machine, the environment, or even the person using it. In this blog, we’ll explore what materials you should avoid when using a laser cutter and why.

PVC (Polyvinyl Chloride)

PVC is one of the worst materials you can try to cut with a laser cutter. When exposed to the laser, it releases harmful chlorine gas, which can be extremely dangerous. This gas can not only damage the laser cutter's components, like the lens and the machine itself, but also pose a severe health risk to anyone nearby. In addition, the residue left behind can corrode the laser cutter over time. For safety reasons, it’s better to avoid PVC altogether.

Why Avoid PVC?

Releases harmful chlorine gas.

Damages the machine.

Poses health risks.

ABS (Acrylonitrile Butadiene Styrene)

ABS plastic is another material that’s best avoided in laser cutting. When cut, ABS releases toxic fumes that can be harmful if inhaled. Additionally, ABS tends to melt rather than vaporize when hit by the laser, which can cause the material to warp or catch fire. This not only produces poor-quality cuts but can also damage the machine or even start a fire.

Why Avoid ABS?

Produces toxic fumes.

It melts and warps easily.

Fire hazard.

Polycarbonate (PC)

Polycarbonate is a tough, transparent plastic often used for items like eyewear lenses and bulletproof windows. However, it’s not suitable for laser cutting. When you try to cut polycarbonate with a laser, it usually turns black, and the laser has a hard time cutting through it cleanly. The result is an unattractive finish, and the material may catch fire as well.

Why Avoid Polycarbonate?

Produces poor-quality cuts.

Difficult to cut cleanly.

Fire risk.

Fiberglass

Fiberglass is made from a combination of glass and resin. When you attempt to laser cut fiberglass, it can release harmful gases from the resin, while the glass fibers can damage the laser cutter. The material does not cut cleanly, leaving rough and uneven edges. Plus, the tiny glass particles can scratch and damage the laser optics, leading to costly repairs.

Why Avoid Fiberglass?

Releases harmful fumes.

Damages the laser optics.

Cuts unevenly.

Coated Carbon Fiber

While some carbon fiber materials can be laser cut, those that are coated with resins or other finishes should be avoided. The coating can produce toxic fumes, which are not only harmful to the operator but also dangerous for the machine. Additionally, the coating may cause the material to burn unevenly, leading to poor results and potential machine damage.

Why Avoid Coated Carbon Fiber?

Produces toxic fumes.

Causes uneven burns.

Risk of machine damage.

Polystyrene Foam

Polystyrene foam, often known as Styrofoam, is a very lightweight material. However, it’s not a good candidate for laser cutting. This material can easily catch fire and melt, releasing harmful fumes. The foam can also produce very uneven cuts, making it difficult to achieve a clean finish. Additionally, the foam particles can clog the laser cutter, requiring frequent cleaning and maintenance.

Why Avoid Polystyrene Foam?

High fire risk.

Produces toxic fumes.

Clogs the machine.

Printed Circuit Boards (PCBs)

Printed circuit boards are an essential part of many electronic devices, but they are not ideal for laser cutting. PCBs are typically made of layers of materials like fiberglass and copper, which don’t respond well to laser cutting. The fiberglass can release harmful fumes, while the copper can reflect the laser, potentially damaging the machine. Also, the laser cutter may struggle to cut through multiple layers, leaving poor-quality cuts.

Why Avoid Printed Circuit Boards?

Releases harmful fumes.

Copper reflects the laser.

Poor-quality cuts.

Glass

While glass can be engraved using a laser cutter, it’s not recommended for cutting. Glass doesn’t cut well with lasers because it tends to crack or shatter under the heat. If you try to cut glass with a laser, the result will likely be jagged edges and broken pieces. It’s better to use other tools like water jets or diamond cutters for glass cutting.

Why Avoid Glass?

Cracks or shatters.

Leaves jagged edges.

Difficult to cut cleanly.

Teflon (PTFE)

Teflon is known for its non-stick properties and is often used in cookware and industrial applications. However, it’s not suitable for laser cutting. Teflon releases toxic fumes when heated, which can be dangerous to inhale. These fumes can also damage the laser cutter over time. In addition, Teflon tends to melt rather than vaporize, resulting in poor-quality cuts.

Why Avoid Teflon?

Produces toxic fumes.

Melts easily.

Poor-quality cuts.

Leather with Chromium Tanning

Leather is a material often used in laser cutting, but it’s essential to know how it’s tanned. Leather tanned with chromium should be avoided because it releases harmful fumes when cut. These fumes are not only bad for your health but can also damage the laser cutter. Vegetable-tanned leather, on the other hand, is a safer option for laser cutting.

Why Avoid Chromium-Tanned Leather?

Releases toxic fumes.

Harms health and machinery.

Final Thoughts!

Laser cutting is an incredible tool, but it’s important to know which materials should be avoided. Cutting the wrong materials can lead to toxic fumes, machine damage, and even personal harm. Always double-check the material before starting a laser-cutting project, and if in doubt, consult the manufacturer’s guidelines. Safety comes first, and by following these tips, you can keep your laser cutter running smoothly and produce high-quality results.