What Is Rapid Prototyping? Benefits and Best Practices

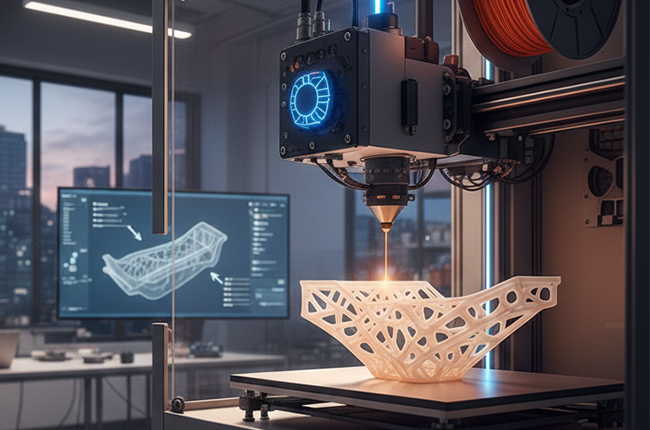

When time-to-market is critical, rapid prototyping provides a clear advantage. It turns digital concepts into working models that can be tested and refined with ease. Designers and engineers can quickly create physical versions of their ideas, evaluate performance, and make improvements before mass production. With the support of 3D printing rapid prototyping, and advanced additive manufacturing techniques, companies can cut risks, lower costs, and bring innovations to the market faster.

What Is Rapid Prototyping?

Rapid prototyping is the process of quickly creating a scale model or functional part using computer-aided design (CAD) and specialized manufacturing technologies. Unlike traditional methods that require molds or long machining processes, this approach produces working prototypes in a fraction of the time. Industries such as automotive, healthcare, aerospace, and consumer electronics rely heavily on this process to validate designs and test usability.

Benefits of Rapid Prototyping

There are several reasons why rapid prototyping has become essential in product development:

Shortens the design-to-production cycle.

Prototypes can be built in hours or days instead of weeks, allowing faster testing and quicker decisions. This helps companies reduce time-to-market for new products.Reduces the need for expensive tooling at early stages.

Since molds or specialized equipment are not required upfront, businesses can experiment with designs without heavy financial risks. This keeps development costs under control.Provides physical models for testing and improving usability.

Having a tangible prototype allows designers, engineers, and end-users to interact with the product. This leads to better feedback and more user-friendly final designs.Identifies design flaws before full-scale production begins.

Early testing helps spot issues in structure, fit, or function before mass production. This prevents costly redesigns and minimizes the chances of product failure.

These advantages make rapid prototyping a key step for businesses that aim to stay competitive.

Techniques Used in Rapid Prototyping

The success of rapid prototyping comes from the methods used to create models. The most common are:

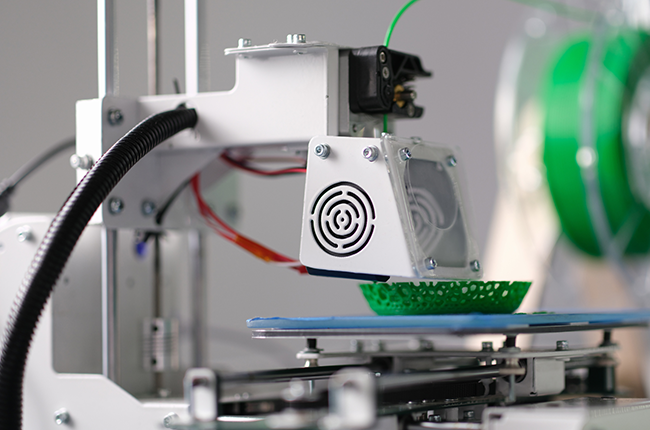

Additive manufacturing techniques such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Subtractive methods like CNC machining for precise parts.

Virtual prototyping, where simulations test a product digitally before physical creation.

Today, 3D printing rapid prototyping stands out as the most widely used due to its flexibility, accuracy, and affordability.

Applications of Rapid Prototyping

The uses of rapid prototyping go beyond simple models. Some common applications include:

Product design and testing – Validating concepts before large investments.

Medical field – Custom implants, surgical guides, and anatomical models.

Automotive and aerospace – Testing lightweight, complex parts.

Consumer goods – Fast iterations for electronics and household products.

Challenges and Limitations of Rapid Prototyping

Although highly effective, rapid prototyping is not without drawbacks. Some of the common challenges include:

Limited material strength for certain applications.

Inconsistent surface finish depending on the method used.

High cost of advanced additive manufacturing techniques and equipment.

Not always suitable for large-scale production.

Design accuracy can vary with complex geometries.

Future of Rapid Prototyping

The future of rapid prototyping looks promising. With continuous improvements in speed, accuracy, and material options, it is becoming a standard step in product development. Integration with digital technologies will expand possibilities, allowing industries to move from concept to market faster than ever.

Summing Up!

Rapid prototyping has transformed the way products are designed and tested. From creating functional models to validating complex parts, it gives businesses the confidence to move forward with production. Supported by 3D printing rapid prototyping, and advanced additive manufacturing techniques, this process is shaping the future of innovation across industries.