What Is a Height Master and Why Is It Essential in Dimensional Inspection?

When it comes to precision, nothing can be left to chance. A Height Master provides a reliable reference for verifying and calibrating measuring instruments, ensuring accuracy across the board. From height gauges to micrometers, this tool is essential for maintaining precision calibration and supporting thorough dimensional inspection. In this blog, we’ll explore how it works, its practical applications, and the multiple benefits it brings to manufacturing and lab environments. With a height gauge, professionals can achieve consistent, traceable measurements that uphold the highest standards of quality and reliability.

What Is a Height Master?

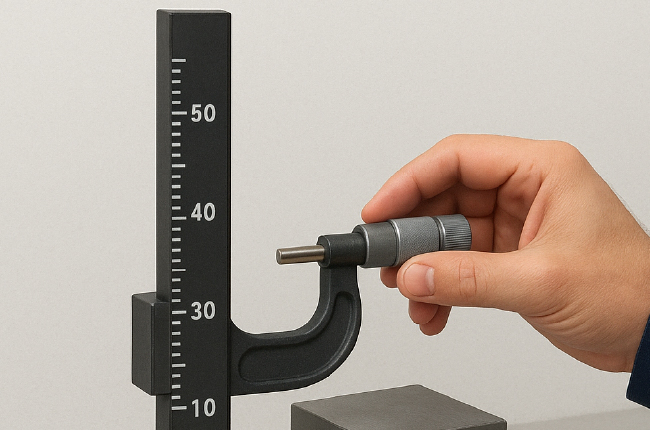

A Height Master is a precision reference tool used to calibrate and verify measuring instruments such as height gauges, micrometers, and other devices that measure vertical dimensions. Essentially, it acts as a benchmark, ensuring that your tools provide accurate readings every time.

Typically, a master gauge consists of precision blocks with known heights, a flat base, and a fine scale for exact measurements. Some advanced versions include digital readouts, making the calibration process even simpler and more reliable.

How a Height Master Works?

The concept behind a master gauge is simple yet highly effective. By providing a known, fixed height, it allows technicians to compare and adjust other measuring instruments. For example, a height gauge can be checked against the master blocks, and any deviation can be corrected immediately.

This ensures that all measurements remain consistent, which is especially important in production environments where precision matters. Using a height gauge guarantees that measurements are traceable and aligned with international standards.

Importance of a Height Master in Dimensional Inspection

Dimensional inspection is the backbone of quality assurance. Without accurate tools, manufacturers risk producing defective parts that may not meet specifications. A height gauge plays a vital role in this process.

By serving as a reference standard, it ensures that height gauges and other measuring instruments are accurate. This reduces errors, improves reliability, and supports precision calibration efforts. Whether in a lab or on the shop floor, the height gauge helps maintain consistency and confidence in measurements. Dimensional inspection is the backbone of quality assurance. Without accurate tools, manufacturers risk producing defective parts that may not meet specifications. A height gauge plays a vital role in this process.

By serving as a reference standard, it ensures that height gauges and other measuring instruments are accurate. This reduces errors, improves reliability, and supports precision calibration efforts. Whether in a lab or on the shop floor, the height gauge helps maintain consistency and confidence in measurements.

Common Applications

Master gauges are widely used in laboratories, tool rooms, and manufacturing facilities. Some common applications include:

Calibrating height gauges to verify vertical measurements.

Check depth micrometers and dial indicators.

Supporting quality control in machining, aerospace, automotive, and electronics industries.

In all these applications, the Height Master provides a stable and precise reference, ensuring that measurements are accurate and reproducible.

Benefits of Using a Height Master

Using a height gauge offers several advantages that make it indispensable in precision measurement and dimensional inspection:

Accuracy:

A Height Master acts as a reliable reference standard with precisely known heights. By calibrating instruments against it, you ensure that all measurements are correct. This reduces the risk of errors that can lead to defective products, rework, or costly delays. Accurate measurements also help maintain product quality and customer satisfaction.Consistency:

When multiple measuring instruments are calibrated using the same height gauge, they produce consistent readings. This is crucial in manufacturing, where even small variations can affect assembly or product performance. Consistency ensures that all tools “speak the same language” and deliver uniform results across different machines or operators.Traceability:

A Height Master is usually calibrated to national or international standards. This means all measurements taken with instruments verified against it are traceable. Traceability is essential for compliance with quality management systems like ISO 9001 or ISO/IEC 17025. It provides confidence that your measurements meet recognized benchmarks and can stand up to audits or inspections.Efficiency:

Using a height gauge speeds up the calibration and verification process. Instead of manually checking each instrument against multiple references, a single height gauge provides a quick and precise standard. This saves time in the inspection process, allowing teams to focus on production and quality assurance rather than repetitive measurements.

Maintenance and Best Practices

To get the most out of a height gauge, proper care is essential. Always store it in a clean, temperature-controlled environment to prevent warping or corrosion. Regularly clean the surface and check for wear or damage.

Periodic calibration against national or international standards ensures that your height gauge remains reliable. Following these best practices prolongs its lifespan and maintains the accuracy of all instruments it calibrates.

Final Thoughts

A height gauge is more than just a measuring block—it is the foundation of precision in manufacturing and labs. It supports precision calibration, enhances dimensional inspection, and ensures that all measuring tools deliver accurate and consistent results.

Investing in a Height Master helps manufacturers and quality control teams maintain high standards, reduce errors, and build trust with clients. In a world where even small measurement mistakes can have significant consequences, a height gauge is truly indispensable.