Welding Defects and Quality Checks: Best Practices

Welding plays a key role in almost every manufacturing and fabrication process. From automotive to aerospace, construction to machinery — welding joins materials with strength and precision. But when not done correctly, it can lead to welding defects that weaken the structure and affect performance. That’s why proper quality checks in welding are so important to ensure the final product meets international standards. This blog explores the most common welding defects, how they occur, and the best practices for quality checks that maintain strong and durable welds.

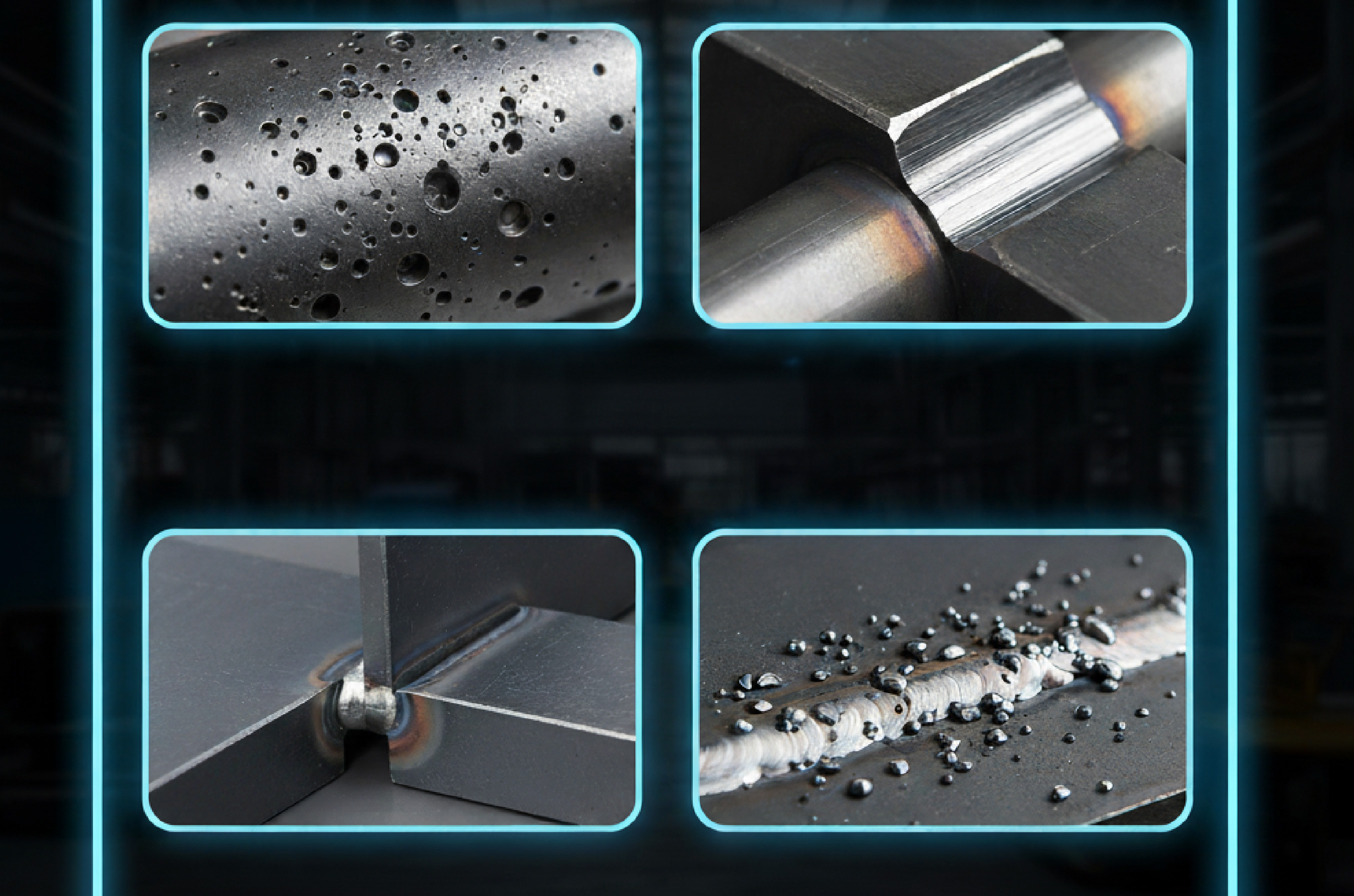

Understanding Welding Defects

A welding defect is any irregularity or flaw that affects the strength, appearance, or function of a welded part. Even a small defect can lead to costly failures, downtime, or safety hazards. That’s why identifying and preventing these defects early is vital in any metal fabrication or manufacturing setup.

Let’s look at some of the most common welding defects found across industries.

Common Types of Welding Defects

1. Porosity

Porosity happens when gas gets trapped inside the weld metal, creating small holes or cavities. This weakens the joint and makes it prone to cracking. It often occurs due to improper shielding gas, moisture, or contamination on the surface.

2. Cracks

Cracks are among the most dangerous defects in welding. They can appear during or after the welding process and may spread under stress or vibration. Cracks usually result from high residual stress, poor joint design, or improper cooling.

3. Undercut

An undercut occurs when the weld metal erodes the base material along the edge of the weld, reducing its strength. This usually happens due to incorrect welding parameters, such as high current or fast travel speed.

4. Incomplete Fusion

Incomplete fusion means that the weld metal has not fully fused with the base metal or between weld passes. It’s often caused by low heat input, poor technique, or improper positioning.

5. Slag Inclusion

Slag inclusion occurs when non-metallic particles get trapped inside the weld. This defect weakens the weld and can lead to failure under stress. The main reasons are poor cleaning between passes and incorrect electrode angles.

6. Spatter

Spatter refers to small molten droplets that stick to the surface near the weld bead. While it doesn’t usually affect the strength of the weld, it reduces the overall appearance and requires extra cleaning.

Why Quality Checks in Welding Are Important

Quality checks in welding ensure that every weld meets the strength, durability, and safety requirements needed for its application. Without proper inspection, defects can go unnoticed and cause major problems during operation.

For industries like aerospace, automotive, oil and gas, and heavy engineering, consistent quality control is not optional — it’s a must. Quality checks help in:

Preventing product failure and costly repairs

Meeting international safety standards

Improving the life span of welded components

Maintaining the company’s reputation and customer trust

Best Practices for Welding Quality Checks

1. Visual Inspection

This is the first and simplest step in any welding quality check process. Trained inspectors look for visible defects such as cracks, porosity, or incomplete fusion. Good lighting, magnifiers, and mirrors are often used to ensure no defect is missing.

2. Non-Destructive Testing (NDT)

Non-destructive testing helps detect internal defects without damaging the part. Common NDT methods include:

Ultrasonic Testing (UT): Uses sound waves to find internal cracks.

Radiographic Testing (RT): Uses X-rays or gamma rays to detect hidden flaws.

Magnetic Particle Testing (MT): Finds surface and near-surface defects in ferromagnetic materials.

Dye Penetrant Testing (PT): Detects surface cracks and porosity.

These tests are widely used in industries where safety and precision are critical.

3. Destructive Testing

In some cases, samples are intentionally destroyed to understand the weld’s strength and performance. Tests like tensile testing, bend testing, and impact testing help engineers confirm that welds can withstand real-world loads and conditions.

4. Process Control and Documentation

Every welding process must follow a Welding Procedure Specification (WPS) that defines parameters like voltage, current, filler material, and technique. Regular documentation and monitoring ensure consistency across production.

5. Skilled Welders and Training

Even with advanced machines, the skill of the welder matters most. Regular training, certification, and evaluation help maintain consistent welding quality and reduce the chances of defects.

Preventing Welding Defects: Best Practices

Quality control is not just about checking after welding — it begins before the first arc is struck. Here are some proven best practices:

Always clean the base material to remove oil, rust, and moisture.

Use the right filler metal and electrode type for the job.

Maintain proper heat input and travel speed.

Ensure correct alignment and joint design.

Store consumables in dry and controlled conditions.

Follow proper welding sequences to minimize stress and distortion.

By applying these practices, manufacturers can reduce rework, save costs, and achieve stronger, cleaner welds.

The Role of Technology in Welding Quality

Today, advanced welding technology and automated systems have made it easier to maintain precision and quality. Modern machines can monitor temperature, voltage, and current in real-time, helping to detect defects early.

Integration with CAD-CAM systems and robotic welding ensures consistent results, especially in high-volume production.

These technologies also improve traceability — making it possible to record every weld parameter for future reference, which is essential for industries that follow strict quality standards.

Conclusion

Maintaining high-quality welding standards is essential for safety, performance, and customer satisfaction. Understanding welding defects, using proper inspection methods, and following quality control best practices can help prevent costly failures and rework.

At VmakeU, we combine skilled craftsmanship with advanced welding technologies to deliver defect-free, high-precision components for global industries. Whether it’s aerospace, automotive, or heavy machinery, our focus is always on quality, reliability, and performance.

Partner with VmakeU for your next fabrication or welding project and experience manufacturing excellence built on precision and trust.