VMM vs. VMS: Understanding the Differences and Applications

Choosing the right inspection system can make a big difference in product quality and production speed. This blog compares VMM vs VMS, two powerful tools used for precision measurement. A Video Measuring Machine excels in high-precision inspections of small, intricate parts, while a Video Measuring System focuses on speed and versatility for larger components and production lines. We will explore their differences, applications, costs, and real-world use cases to help manufacturers select the best solution for their needs.

What is a VMM (Video Measuring Machine) ?

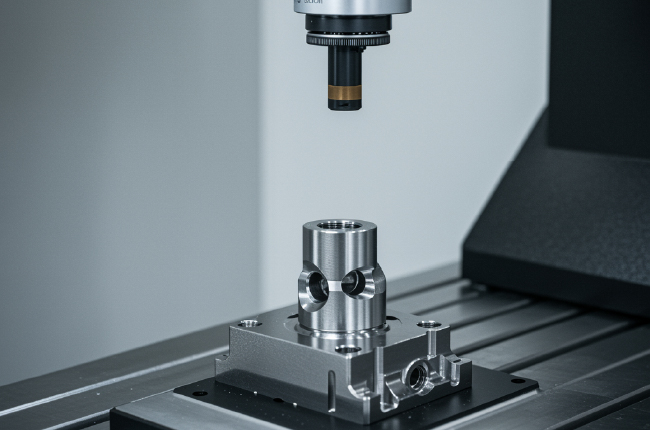

A Video Measuring Machine is designed for high-precision inspection of small or intricate parts. It uses cameras and sensors to capture detailed images of a component and software to measure dimensions accurately.

VMM is ideal for electronics, medical devices, and parts where accuracy is critical. It provides high-resolution measurements and can detect even tiny deviations. The main advantage is precision, but it may be slower for large-scale inspections.

What is a VMS (Video Measuring System) ?

A Video Measuring System is built for faster and broader inspection tasks. It can handle larger parts or multiple components on production lines. VMS integrates with automated systems and software to provide quick results without compromising accuracy.

Unlike a VMM, a VMS focuses on speed and versatility. It is common in automotive, aerospace, and industrial manufacturing, where high-volume inspection is needed. Its main strength is efficiency, although it may be slightly less precise than a VMM for tiny details.

VMM vs VMS: Key Differences

When comparing VMM vs VMS, several factors help manufacturers decide which system fits their needs:

Accuracy: A Video Measuring Machine (VMM) is built for high-precision measurements. It can detect tiny deviations in small or intricate components, making it ideal for industries like electronics or medical devices where even minor errors can have a big impact. On the other hand, a Video Measuring System (VMS) prioritizes speed while maintaining reasonable accuracy. It is suitable when you need reliable measurements but doesn’t require ultra-fine precision for every single part.

Speed: VMS is designed for faster inspection and can handle multiple parts quickly, which makes it perfect for production lines and high-volume operations. VMM, while extremely precise, operates at a slower pace because it focuses on meticulous measurement of each component. The trade-off is clear: speed versus detailed accuracy.

Complexity: Operating a VMM requires careful setup, calibration, and understanding of measurement techniques. Its software is often more advanced, giving experts full control over precision. VMS, by contrast, is easier to operate for large-scale inspections. It integrates smoothly with production line systems and can be operated with minimal training, making it user-friendly for ongoing inspections.

Cost: Precision comes at a price. VMMs tend to be more expensive due to their sophisticated optics, high-resolution cameras, and advanced software. VMS provides cost savings when inspecting large batches of parts quickly, making it a practical choice for industries focused on efficiency and scale.

Use Case: The choice between VMM and VMS depends on your inspection priorities. Use a VMM for detailed, critical inspections of small parts where accuracy cannot be compromised. Use a VMS for quick, versatile measurements across multiple parts or larger components where efficiency is more important than ultra-fine detail.

Choosing Between VMM and VMS

Selecting the right system starts with understanding your manufacturing requirements. If your components are small, delicate, or require extremely precise measurements, a Video Measuring Machine is the ideal solution. It ensures accuracy down to the micron level and reduces the risk of defects.

If your priority is speed and efficiency, or if you need to inspect multiple parts simultaneously, a Video Measuring System is better suited. It works well for large components or assembly lines where high throughput is required without significantly compromising accuracy.

Before making a decision, consider these factors:

Part Size: Smaller, intricate parts benefit more from VMM, while larger parts are better handled by VMS.

Inspection Volume: High-volume inspections favor VMS for faster results.

Budget: VMM may require a higher initial investment, whereas VMS is more cost-effective for large-scale operations.

Software Integration: Consider how the system will integrate with your existing inspection processes and software.

By evaluating these factors carefully, manufacturers can choose the system that maximizes both performance and cost efficiency.

Real-World Applications

Here are some real word application of VMM & VMS :

VMM Applications: VMMs excel in industries that demand high precision. This includes electronics (circuit boards, microchips), medical devices (surgical tools, implants), and small mechanical components where even minor deviations can lead to major problems.

VMS Applications: VMS is widely used in industries requiring fast, versatile inspections. Automotive manufacturing benefits from VMS in engine parts and assembly lines. Aerospace industries use VMS for larger components like panels and assemblies. Industrial manufacturing also uses VMS for large batches of parts where speed and consistency are crucial.

Conclusion

In the debate of VMM vs VMS, the choice depends on precision and production needs. VMM excels in detailed, small-scale inspections, while VMS offers speed and versatility for larger parts. By knowing their strengths, manufacturers can improve quality, reduce waste, and optimize production.