Understanding the Science Behind Sheet Metal Forming and Bending

Sheet metal forming and bending are essential processes in manufacturing and engineering. They are used to create parts and components from thin, flat pieces of metal. Whether it’s for car bodies, aircraft panels, or household appliances, understanding these processes can help us appreciate the technology and craftsmanship involved in making everyday objects. In this blog, we will explore the basics of sheet metal forming and bending, explaining the science behind them in simple terms.

What is Sheet Metal Forming?

Sheet metal forming is a process used to shape metal sheets into desired forms without cutting or removing any material. It involves applying force to the metal to deform it. This process allows manufacturers to create complex shapes and designs from flat sheets of metal, making it versatile and cost-effective.

Types of Sheet Metal Forming

Stamping: This is one of the most common methods. In stamping, a sheet of metal is placed in a machine called a press. The press has a die (a special tool) that shapes the metal as it presses down. Think of it like a cookie cutter, but for metal.

Deep Drawing: This technique is used to create cup-like shapes from a flat sheet. Imagine pressing a piece of dough into a deep mold to make a bowl shape. In deep drawing, a punch pushes the metal into a die to form deep, hollow shapes.

Spinning: This method involves rotating the metal sheet and forming it over a mold using a tool. Picture a potter’s wheel where the clay is spun and shaped into a pot. Similarly, metal can be spun and formed into cylindrical shapes like pots and pans.

What is Bending?

Bending is a type of sheet metal forming where the metal is deformed along a straight axis to create an angle or curve. It’s a fundamental process used to make parts like brackets, enclosures, and frames.

The Science Behind Bending

When metal is bent, the side facing the inside of the bend compresses, while the side facing the outside stretches. This is due to the material's properties, which allow it to deform without breaking. Here’s a breakdown of the key concepts:

Elastic Deformation: When the force is first applied to the metal, it bends slightly. If the force is removed, the metal will spring back to its original shape. This is because the material is still within its elastic limit.

Plastic Deformation: If more force is applied, the metal bends further and reaches a point where it will not return to its original shape when the force is removed. This permanent bending is called plastic deformation.

Neutral Axis: During bending, there’s an imaginary line within the metal that doesn’t stretch or compress. This line is called the neutral axis. The metal above this line compresses, while the metal below stretches.

Tools and Machines Used

Several tools and machines are used in sheet metal bending:

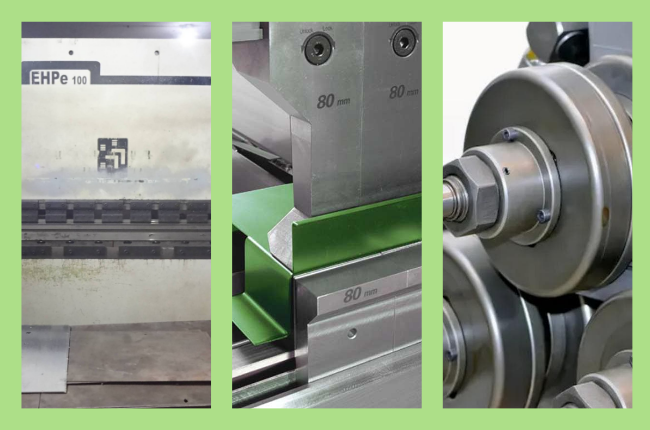

Press Brake: This machine uses a punch and die to bend metal sheets into precise angles and shapes. The metal sheet is placed on the die, and the punch presses down to create the bend.

Folding Machine: This tool is used to create straight bends by clamping the metal and folding it along a straight line.

Roll Bending Machine: This machine uses three rollers to bend metal into curved shapes. The metal sheet passes through the rollers, which apply pressure to create a curve.

Applications of Sheet Metal Forming and Bending

Sheet metal forming and bending are used in many industries:

Automotive Industry: Car bodies, frames, and various components are made using these processes.

Aerospace Industry: Aircraft panels, wings, and other parts are formed and bent to precise shapes.

Construction: Metal roofing, structural supports, and HVAC components are created through sheet metal forming and bending.

Consumer Goods: Appliances, furniture, and electronic enclosures often involve these techniques.

Conclusion

Understanding the science behind sheet metal forming and bending helps us appreciate the complexity and precision involved in making metal parts.

These processes combine the principles of physics and material science to transform flat sheets of metal into functional, durable components. From cars to kitchen appliances, the products we use every day rely on these fascinating techniques.