Understanding Sheet Metal Forming: From Concept to Final Product

Sheet metal forming is one of the most important processes in modern manufacturing. It’s the art and science of turning flat sheets of metal into parts, components, and structures that power industries across the world — from aerospace and automotive to electronics and energy. Whether you’re building an aircraft component, a car body, or a machine enclosure, sheet metal forming helps shape ideas into real, functional products. In this blog, we’ll take you through the complete journey — from concept to the final product — and help you understand why sheet metal forming is such a critical part of global manufacturing.

What Is Sheet Metal Forming?

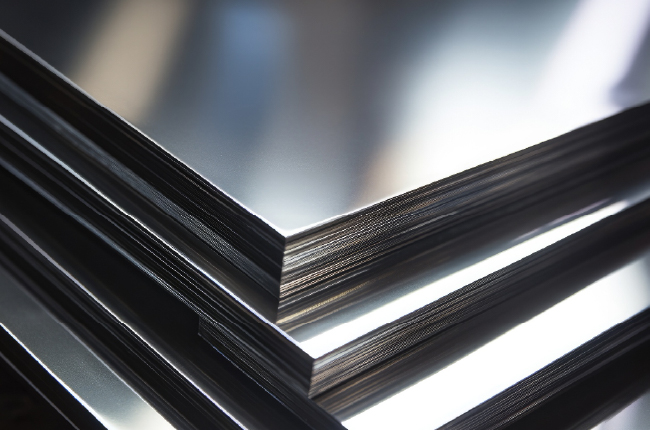

Sheet metal forming is a manufacturing process that bends, stretches, or shapes flat sheets of metal into specific forms using mechanical force. These metals can include steel, aluminum, copper, brass, or titanium — depending on the end-use.

The process can be done manually or with the help of machines such as press brakes, stamping presses, or roll formers. The goal is simple — to create high-quality parts with accurate dimensions, smooth finishes, and excellent strength.

Step 1: Concept and Design in Sheet Metal Forming

Every successful sheet metal product begins with a concept. This stage involves understanding what the product needs to do, how it will look, and what materials are best suited.

Design engineers use CAD (Computer-Aided Design) software to create 3D models of the part. These designs are then analyzed for manufacturability — ensuring that the shapes, bends, and cuts are practical and cost-effective.

At this stage, precision matters. A well-thought-out design saves time, reduces waste, and ensures better quality during production.

Step 2: Choosing the Right Sheet Metal Material

Material selection is a key part of the sheet metal forming process. The right metal determines the strength, durability, and performance of the final product.

Here are some commonly used materials:

Aluminum: Lightweight and corrosion-resistant, ideal for automotive and aerospace applications.

Steel: Strong, versatile, and widely used for construction and machinery parts.

Stainless Steel: Resistant to rust and heat, perfect for medical and food equipment.

Copper and Brass: Great for electrical and decorative components.

Each material behaves differently under pressure, so understanding its properties helps in achieving the desired shape without cracks or defects.

Step 3: The Sheet Metal Forming Process

Once the design and material are ready, the forming process begins. Depending on the shape and function of the part, different sheet metal forming techniques are used.

1. Bending

Bending uses machines like press brakes to fold the metal into a required angle or shape. It’s a precise process that requires the right combination of force, tooling, and material thickness.

2. Deep Drawing

This technique forms metal sheets into cup-like or hollow shapes. It’s widely used in manufacturing cans, sinks, and automotive fuel tanks.

3. Stamping

Stamping involves pressing the metal into a die to cut or shape it. It’s ideal for mass production where uniformity and speed are required.

4. Roll Forming

In this method, the sheet metal passes through a series of rollers that gradually shape it into a desired profile. It’s perfect for producing long, continuous parts like pipes and channels.

5. Stretch Forming

Here, the metal sheet is stretched over a die to form large, curved surfaces — often used in aircraft panels or architectural applications.

Each of these metal forming processes help create components with high accuracy and excellent repeatability.

Step 4: Finishing and Assembly

After forming, the metal parts undergo finishing to improve their appearance, durability, and performance. Finishing may include processes like deburring, polishing, coating, or painting.

If multiple parts are made, they are then assembled using techniques such as welding, riveting, or bolting. Quality checks are done at every stage to ensure each part meets the required standards.

The result is a finished product that’s ready to be used — strong, reliable, and visually appealing.

Step 5: Quality Control in Sheet Metal Forming

Quality control plays a big role in sheet metal manufacturing. Every dimension, curve, and joint must be accurate.

Modern companies use CNC machines, laser measuring tools, and automated inspection systems to maintain consistency and precision. These technologies help reduce human error and ensure every product matches the design exactly.

Why Sheet Metal Forming Matters

Sheet metal forming isn’t just about bending metal — it’s about bringing innovation to life. It helps industries:

Reduce production costs

Speed up manufacturing cycles

Improve product strength and design flexibility

Maintain high precision for complex parts

From small electronics to massive aircraft structures, sheet metal fabrication and forming support almost every modern industry.

VmakeU: Your Global Partner in Sheet Metal Forming

At VmakeU, we specialize in custom sheet metal forming and fabrication for a wide range of industries — including aerospace, automotive, machinery, and renewable energy.

Our advanced equipment, skilled engineers, and commitment to quality ensure that every product meets global standards. From concept to final delivery, we make sure your vision takes the right shape — efficiently, precisely, and cost-effectively.

If you’re looking for a trusted partner for sheet metal forming and fabrication, VmakeU is here to support your project from start to finish.