Understanding Lean Manufacturing Methods/ JIT (just in time)

Lean manufacturing and Just-In-Time (JIT) are popular terms in the business world, especially in industries that focus on production and supply chains. If you’re new to these concepts, don’t worry! In this blog, we’ll break down these ideas in simple words so you can understand how they work and why they matter.

What is Lean Manufacturing?

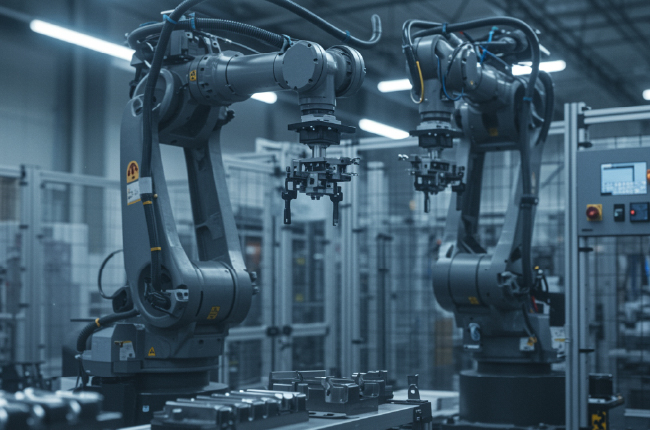

Imagine running a factory where nothing goes to waste. Every resource—time, materials, and even labor—is used efficiently. That’s the core idea of lean manufacturing.

Lean manufacturing is a method aimed at minimizing waste while maximizing value for the customer. Waste here doesn’t only mean physical materials; it also includes wasted time, extra steps in a process, or making more products than needed.

This approach started in Japan, with companies like Toyota leading the way. Their goal was to produce high-quality cars without overusing resources. Over time, many industries worldwide adopted lean practices because they save money and improve productivity.

What is JIT (Just-In-Time)?

Now let’s talk about Just-In-Time (JIT). It’s a key part of lean manufacturing. JIT is all about producing what you need, when you need it, and in the right amount.

For example, imagine running a bakery. Instead of baking 500 loaves of bread and risking half of them going stale, you bake just enough to meet your orders. That way, there’s no waste, and you’re not storing excess inventory.

In a factory, JIT means materials arrive only when they’re needed, and products are made just in time to meet demand. This reduces storage costs, minimizes waste, and ensures that products are always fresh or up to date.

The Key Principles of Lean and JIT

Here are some basic principles that guide lean manufacturing and JIT:

1. Focus on Customer Value

Only produce what the customer truly wants. Avoid making unnecessary items.

2. Eliminate Waste

Waste comes in many forms—overproduction, delays, extra movement, defects, or excess inventory. The goal is to remove all of these.

3. Continuous Improvement

Always look for ways to improve processes. Even small changes can make a big difference over time.

4. Respect for People

Everyone, from factory workers to managers, plays an important role. Collaboration and respect are essential for success.

5. Smooth Workflow

The process should flow without interruptions. Bottlenecks or delays should be fixed quickly.

Benefits of Lean and JIT

Now that you know what lean manufacturing and JIT are, let’s see why so many companies use them.

1. Lower Costs

By reducing waste and unnecessary inventory, companies save a lot of money.

2. Better Quality

Focusing on customer needs ensures that products meet high-quality standards.

3. Faster Production

With efficient workflows, products are made and delivered quickly.

4. Flexibility

JIT allows companies to adapt to changes in customer demand without overproducing.

5. Happier Customers

Customers get the products they want when they want them, which boosts satisfaction and loyalty.

Real-Life Example: How Toyota Uses JIT

The best example of JIT in action is Toyota. The company revolutionized manufacturing by implementing this system in its factories.

Here’s how it works:

Toyota doesn’t store large amounts of car parts in its factories. Instead, parts are delivered exactly when they’re needed on the assembly line.

Workers and machines are organized in a way that ensures smooth production with no delays.

If a problem occurs, the production line is stopped immediately to fix the issue. This ensures high-quality cars every time.

This method helped Toyota become one of the most successful car manufacturers in the world.

Challenges of Lean and JIT

While lean and JIT have many benefits, they’re not without challenges.

1.. Dependence on Suppliers

JIT relies heavily on suppliers delivering materials on time. If there’s a delay, production can come to a halt.

2. Demand Fluctuations

Sudden changes in customer demand can be hard to manage.

3. Initial Costs

Setting up lean systems and training employees can be expensive initially.

4. Risk of Disruption

Natural disasters or global events, like pandemics, can disrupt supply chains, making JIT harder to maintain.

How to Start with Lean and JIT

If you’re thinking about applying lean manufacturing or JIT in your business, here’s a simple guide to get started:

1. Identify Waste

Look at your current processes and find areas where resources are wasted.

2. Improve Workflow

Organize tasks in a logical order to reduce delays and extra steps.

3. Work Closely with Suppliers

Build strong relationships with suppliers to ensure timely delivery of materials.

4. Train Your Team

Make sure everyone understands lean principles and their role in the process.

5. Start Small

Implement lean and JIT methods in one part of your business first. Once it works well, expand to other areas.

Final Thoughts

Lean manufacturing and Just-In-Time are powerful tools for businesses looking to improve efficiency and reduce costs. By focusing on customer value and eliminating waste, companies can stay competitive in today’s fast-paced world.

Whether you’re running a factory, a store, or even a small workshop, these methods can help you achieve more with less. So why not give them a try? Start small, stay consistent, and watch your business transform!