The Science Behind Louvers, Slots, and Perforations in Sheet Metal Design

Every curve, cut, and hole in sheet metal design serves a purpose. Louvers, slots, and perforations may look simply, but they play a huge role in how a product performs. From improving airflow to reducing weight and even adding beauty, these small design details can completely change how a metal product functions. Let’s explore the science behind these fascinating features and understand why they matter so much in modern sheet metal fabrication.

Understanding the Role of Louvers, Slots, and Perforations in Sheet Metal Design

Sheet metal is used in almost every industry — from aerospace and automotive to architecture and electronics. But a plain metal sheet cannot meet every requirement. It often needs precise modifications to allow airflow, heat control, or even light passage.

That’s where louvers, slots, and perforations come into play. These features transform a simple sheet into a high-performing, efficient, and functional part.

Louvers in Sheet Metal Design

What Are Louvers?

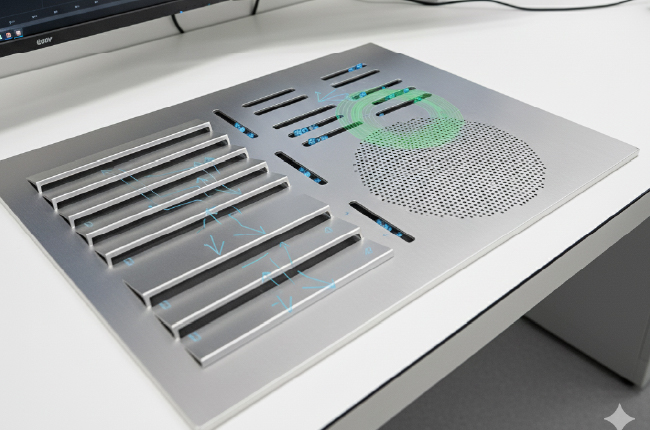

Louvers are raised or angled openings created in a metal sheet to let air or light pass through. They are commonly seen in ventilation systems, automotive panels, and machinery covers.

Their main purpose is to allow airflow while keeping out dust, debris, and water.

The Science Behind Louvers

Louvers work on the principles of aerodynamics and temperature control. When air moves through angled openings, it flows smoothly and helps maintain proper ventilation.

The shape and angle of each louver decide how much air passes through and in which direction. This helps designers create efficient cooling or airflow systems without needing extra fans or vents.

Benefits of Louvers in Sheet Metal Fabrication

Improved ventilation and cooling for enclosed systems.

Lightweight construction without losing strength.

Protection against external dust or rain.

Enhanced appearance for industrial and consumer products.

Slots in Sheet Metal Design

What Are Slots?

Slots are narrow openings cut into metal sheets, often used for assembly, ventilation, or alignment. They can be short or long, straight or curved, depending on the design need.

You’ll find slots in mounting brackets, electrical enclosures, and machine components.

The Science Behind Slots

Slots play an important role in mechanical flexibility and stress management. When a part is mounted using slotted holes, it allows a small range of movement — which helps during assembly or under vibration.

This prevents cracks or deformation that could occur if the part was too rigid.

Benefits of Slots in Metal Design

Easy alignment and installation of components.

Reduced stress by distributing mechanical loads evenly.

Improved flexibility during assembly.

Allows wiring or air passage in compact systems.

Perforations in Sheet Metal Design

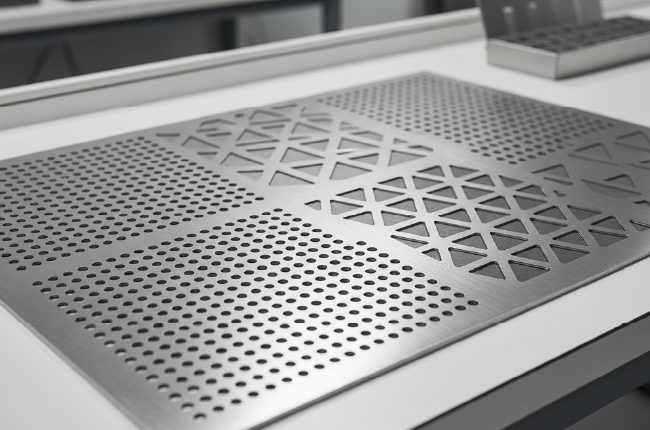

What Are Perforations?

Perforations are a pattern of small holes or shapes punched into a metal sheet. These holes can be round, square, hexagonal, or custom designs — depending on the project.

Perforated metal is widely used in architectural panels, soundproof systems, filters, and lighting fixtures.

The Science Behind Perforations

The science of perforations lies in balancing strength, weight, and performance. When holes are added, the sheet becomes lighter but still strong enough for structural use.

Perforations also allow air, sound, or light to pass through — which is why they are used for ventilation, filtration, and acoustic control.

The pattern, spacing, and size of holes are calculated to achieve the best results.

Benefits of Perforated Sheet Metal

Lightweight and strong at the same time.

Efficient heat and sound control.

Customizable design options for industrial and decorative uses.

Eco-friendly and cost-effective since less material is used.

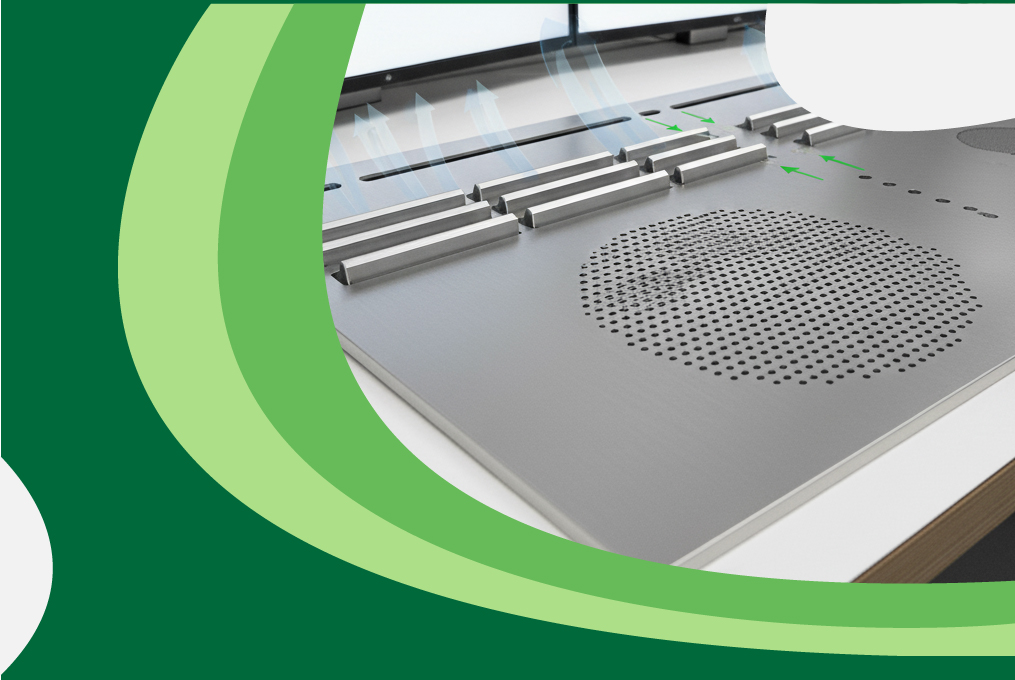

Combining Louvers, Slots, and Perforations for Maximum Efficiency

Modern designs often use all three features — louvers, slots, and perforations — together to achieve better performance.

For example, a machine panel might use:

Perforations for ventilation,

Louvers for controlled airflow, and

Slots for mounting and assembly.

This combination creates a multi-functional metal part that performs efficiently while maintaining strength and visual appeal.

At VmakeU, our engineers design each sheet metal component with precision and purpose. We use advanced laser cutting and CNC punching technologies to produce high-quality louvers, slots, and perforations for industries worldwide.

Applications Across Industries

These small design features play a big role across multiple industries:

Aerospace and Aviation: For ventilation and lightweight panels.

Automotive: In body panels, exhaust shields, and air vents.

Architecture: For building facades, sunshades, and decorative panels.

Electronics: For enclosures, speaker grilles, and heat control systems.

Industrial Equipment: For filters, cooling systems, and machine covers.

Their versatility makes them essential in both functional engineering and aesthetic design.

Innovation and Sustainability in Sheet Metal Design

The latest advances in sheet metal fabrication have made it possible to design complex patterns with minimal waste. Using techniques like laser cutting, precision punching, and 3D modeling, manufacturers can achieve perfect shapes every time.

These innovations reduce material waste and energy use — making the process more sustainable and cost-effective.

At VmakeU, we take pride in delivering custom sheet metal solutions that combine technology, design, and sustainability. Our goal is to help clients achieve products that are not only efficient but also future-ready.

Final Thoughts

Louvers, slots, and perforations might look small, but they have a big impact on sheet metal performance and design. They make metal parts lighter, stronger, and smarter — all while giving them a modern look.

If you’re looking for custom sheet metal fabrication with precision and performance in mind, VmakeU is your trusted partner.

Contact VmakeU today to bring innovation, accuracy, and efficiency to your next metal fabrication project.