The Role of Video Measuring Systems in High-Precision Manufacturing

Every component, whether big or small, must meet strict design standards to ensure performance and safety. Video Measuring Systems (VMS) have become essential tools for achieving this level of precision. They use advanced optics, cameras, and intelligent software to measure parts without physical contact. From delicate electronics to aerospace components, VMS delivers unmatched consistency and speed. This blog highlights how Video Measuring Systems enhance high-precision manufacturing, ensure quality, and simplify complex inspection processes across various industries.

What Are Video Measuring Systems?

A Video Measuring System (VMS) is an optical device that measures parts using high-resolution cameras and computer software. Unlike traditional tools, it captures detailed images and converts them into precise dimensions. The setup includes a camera, lighting, a stage, and analytical software. This combination allows engineers to check small and complex components without physical contact.

Importance in Modern Manufacturing

Every industry, from aerospace to medical devices, demands flawless components that fit and function perfectly. Video Measuring Systems make this possible by offering reliable, repeatable, and damage-free inspection for even the most delicate parts.

Here’s why they are vital in modern manufacturing:

1. Delicate Component Inspection

Many industries work with small, fragile, or flexible materials that can’t be touched by traditional tools. Non-contact measurement ensures the surface remains undamaged while still capturing accurate data. This helps manufacturers maintain product integrity and reduce rework or rejection rates.

2. High Repeatability

Consistency is key in mass production. Video Measuring Systems provide the same accurate results every time. Automated operation reduces human error and ensures identical quality across batches. This leads to higher reliability and stronger customer trust.

3. Faster Inspection Process

Speed matters in high-volume manufacturing. VMS captures multiple dimensions in seconds. With automated focusing and instant data analysis, inspections become faster and smoother. This reduces downtime and increases overall productivity.

4. Enhanced Accuracy

Modern optics and imaging software make Video Measuring Systems far more precise than manual tools. Even micro-sized defects or dimensional variations are detected with ease. This ensures every component meets design tolerances perfectly.

5. Ideal for Complex Geometries

Some parts have intricate designs or hidden features that are hard to measure by touch. A Video Measuring System can capture complex contours and shapes with sharp clarity. This is especially important in advanced manufacturing, like aerospace and electronics.

6. Quality and Cost Efficiency

By minimizing manual errors and rework, VMS helps save time and material costs.

Real-time feedback allows quick correction during production. The result is better quality assurance and higher profitability.

How VMS Ensures High Accuracy?

A Video Measuring System (VMS) ensures accuracy using advanced optics, high-resolution imaging, and smart software. It captures detailed images from multiple angles and analyzes them through precision inspection technology to match design specifications. Proper lighting and focus remove distortions, while software detects features with micron-level accuracy.

Modern VMS connects to CAD models for instant deviation checks. With optical zoom, automated movement, and environmental sensors for temperature and vibration control, it delivers consistent, repeatable, and highly accurate results—making it a trusted tool in precision manufacturing.

Applications Across Industries

Video Measuring Systems are used widely in electronics for chip inspection, in medical manufacturing for device validation, and in the automotive industry for component verification. Wherever high precision is needed, VMS ensures consistent results through non-contact measurement techniques.

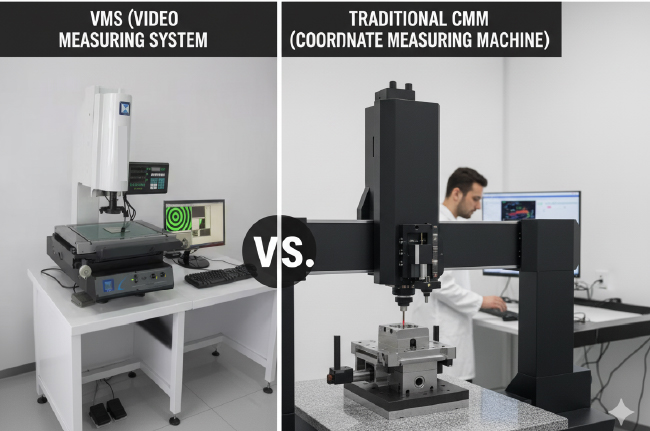

Comparison: VMS vs. Traditional CMMs

Measurement Method

Traditional CMMs use touch probes to make physical contact with the part.

Video Measuring Systems (VMS), on the other hand, use optical and imaging technology for non-contact measurement, reducing the risk of surface damage.Best Different Part Types

CMMs are ideal for large, solid, or heavy components that can withstand touch-based inspection. VMS is better suited for small, fragile, or flexible parts where delicate handling is essential.Accuracy and Detail

Video Measuring Systems capture intricate features and fine details that probes may miss. Their high-resolution imaging ensures sharper, more detailed inspection results.Speed and Efficiency

A VMS can measure multiple dimensions in a single image, making the process faster. In contrast, CMMs take point-by-point readings, which can be slower for complex parts.Combined Use

Many industries use both systems together for maximum coverage. CMMs handle larger geometries, while Video Measuring Systems focus on micro-features and detailed accuracy.

Final Words

Video Measuring Systems are transforming how manufacturers achieve accuracy. They offer speed, reliability, and unmatched precision through advanced imaging and analysis. By combining optical power with intelligent software, VMS helps industries produce better products—faster and with total confidence.