The Role of Reverse Engineering in Modern Manufacturing

Have you ever wondered how manufacturers manage to recreate an old machine part that’s been out of production for decades—or even make it better than before? That’s the power of reverse engineering in manufacturing. It’s not just about taking things apart; it’s about unlocking hidden knowledge, breathing new life into outdated products, and sparking fresh innovation. In today’s fast-moving industries, where every second and every dollar counts, reverse engineering has become the secret weapon for companies that want to stay ahead of the curve. Let’s dive here. Reverse engineering in manufacturing is more than a repair strategy—it’s a pathway to innovation, efficiency, and sustainability. By combining traditional know-how with cutting-edge technologies like 3D scanning and additive manufacturing, businesses are finding smarter ways to solve modern challenges.

What is Reverse Engineering in Manufacturing?

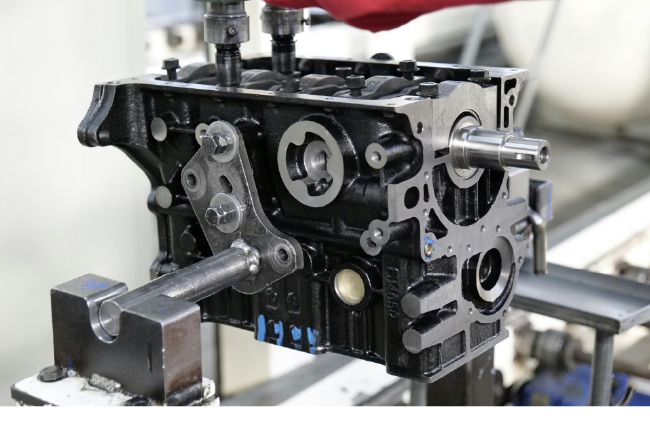

Reverse engineering in manufacturing refers to the process of deconstructing a finished product to understand how it works: its geometry, materials, functional mechanisms, and design intent. Engineers may take apart machines, use measuring tools, or employ digital techniques to recreate models.

This approach originally served sectors like aerospace and defense, but now spans automotive, electronics, medical devices, and consumer goods. MilestoneTech defines reverse engineering as breaking down existing systems to replicate or improve them, which is central to their services.

The Evolution of Reverse Engineering

Over time, reverse engineering in manufacturing has shifted from manual measurement and blueprints to digital workflows. CAD (Computer-Aided Design), CAM systems, and digital twins now enable more precise replication and improvements. Engineers can import 3D scans, convert them into CAD models, simulate performance, and optimize designs before any physical production happens.

Integration with Additive Manufacturing

One of the biggest synergies in modern industry is between reverse engineering in manufacturing and additive manufacturing. Using reverse-engineered 3D models, additive manufacturing (3D printing) allows rapid prototyping, part replacement, and customization without tooling costs. For example, when legacy parts are difficult to source, reverse engineering generates digital models, and additive manufacturing produces replicas. The result: faster lead times, lower waste, and design freedom.

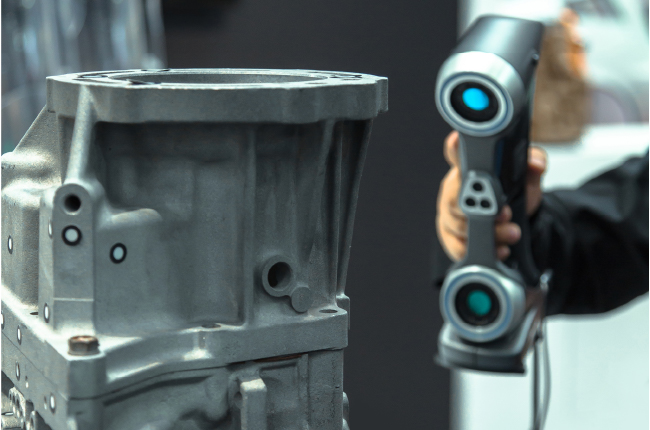

The Role of 3D Scanning Technologies for Reverse Engineering

Another tech that revolutionizes reverse engineering in manufacturing is 3D scanning. High-precision methods like structured-light scanners, laser scanners, or CT scanning capture complex geometries quickly and accurately. These data are converted into point clouds, then into CAD models. Using 3D scanning technologies for reverse engineering, manufacturers can reproduce parts, check quality, and identify design flaws before full-scale production—saving time and cost.

Benefits of Reverse Engineering for Modern Manufacturing

From saving costs to driving innovation, the advantages of reverse engineering in manufacturing are wide-ranging. Here are some of the most impactful benefits it brings to modern industries

Cost Reduction & Resource Optimization: Reverse engineering helps avoid reinventing common designs and reduces prototyping failures.

Product Innovation & Improvement: By dissecting competitor products or older models, manufacturers gain insights that lead to better materials, enhanced features, or improved ergonomics.

Sustainability: Using reverse engineering, companies can reuse existing designs, optimize materials, and reduce waste.

Supply Chain Resilience & Legacy Support: When original suppliers cease production or parts become obsolete, reverse engineering enables reproduction and maintenance.

Challenges and Limitations

Even though reverse engineering in manufacturing has many advantages, there are hurdles: intellectual property (IP) concerns, complex geometries that are hard to measure or scan, high costs for equipment, and the need for skilled engineers. Legal issues can arise, especially when reverse engineering competitor’s products or protected designs. Also, achieving high precision in scanning or modeling is not trivial.

Future Trends in Reverse Engineering

Looking ahead, reverse engineering in manufacturing is likely to be shaped by:

AI & Machine Learning tools that can analyze scanned data, suggest design optimizations, or detect defects autonomously.

Cloud-based collaboration platforms where teams across geographies work on reverse-engineered models.

Tighter integration with Industry 4.0, smart factories, IoT sensors feeding feedback into design loops, making reverse engineering more dynamic.

Final Words

In summary, reverse engineering in manufacturing is not just about copying or replicating old designs—it’s about integrating existing knowledge to innovate, reduce costs, and build sustainable products. When paired with additive manufacturing and enhanced by 3D scanning technologies for reverse engineering, the process becomes a strategic asset. Embracing reverse engineering gives manufacturers the agility to adapt, improve, and lead in a rapidly evolving market.