The Role of Parametric Design in Customizable Product Development

From clothing to consumer electronics, people now want products that reflect their personality and meet specific requirements. This shift has placed customization at the center of product design. By applying parametric design in product development, companies can deliver products that evolve with customer needs while reducing design complexity. This blog shows the benefits of this method.

What is Parametric Design?

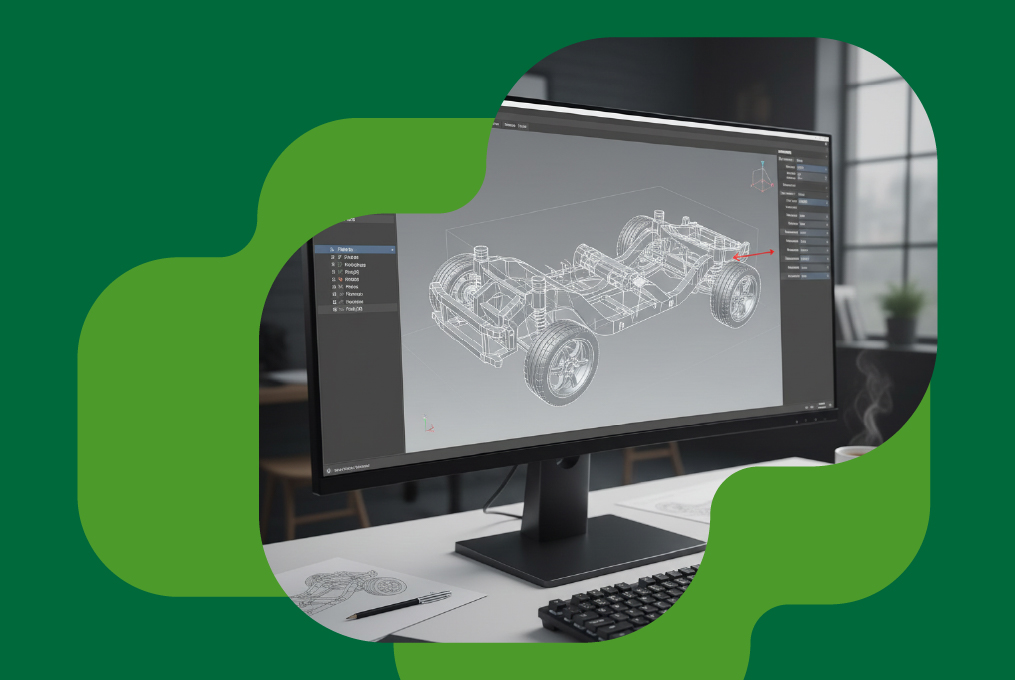

Parametric design in product development uses rules and parameters to define product features. Unlike traditional methods, where every variation requires a new model, parametric design allows changes to be made quickly by adjusting inputs such as size, shape, or material. Modern tools and CAD systems make this process more flexible, allowing designers to create multiple variations with less effort.

Why Customization Matters in Today’s Market

From furniture to footwear, customization has become an expectation rather than a luxury. Businesses that apply parametric design in product development can respond faster to customer needs. This approach helps brands offer unique designs without increasing costs dramatically. Whether it’s adjustable office chairs, personalized sneakers, or modular housing, the ability to adapt products strengthens market competitiveness.

The Role of Parametric Design in Product Development

Together, these approaches show how parametric design in product development will shape the future of customization.

1. Unique Methods

Parametric design works by setting rules and parameters that control product features. Instead of redrawing models for every version, changes can be made by adjusting inputs. This makes the design process faster, more flexible, and more consistent.

2. More Practical to Use

Consumers now expect products that fit their needs, from furniture to fashion. Parametric methods allow designers to create variations without extra effort or cost. This turns personalization into a practical option for businesses.

3. Speed and Efficiency in Development

Traditional design often takes weeks to finalize variations. With parametric tools, updates can happen in minutes, reducing both time and expense. This improves productivity and helps companies stay competitive.

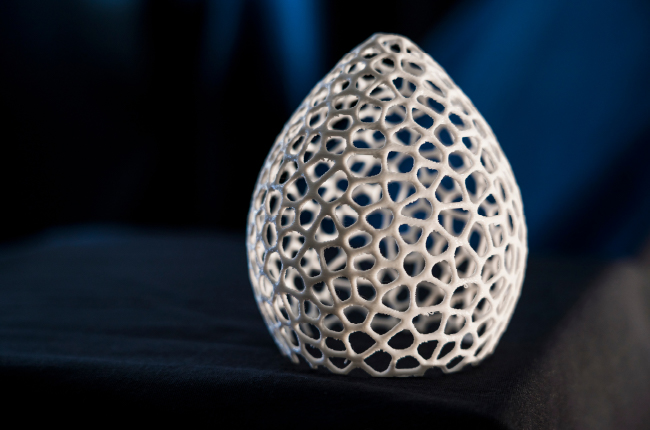

4. Supporting Mass Customization

One strength of parametric design is enabling mass customization through parametric modeling. Businesses can manufacture at scale while still offering unique product options. This balance ensures efficiency without losing variety.

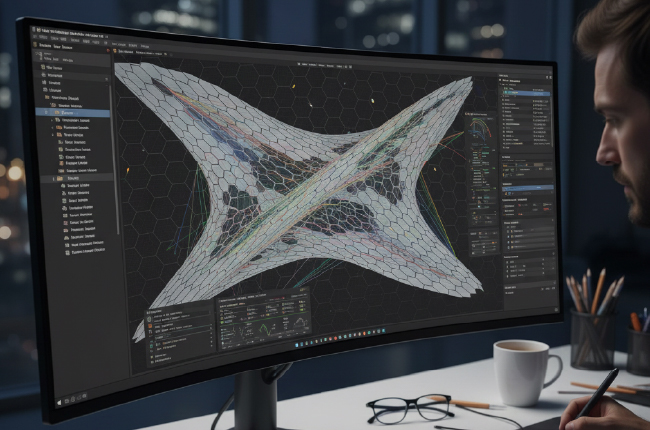

5. Future Potential with Generative Design

When combined with generative design for customizable products, parametric methods reach new levels. They allow automated exploration of multiple solutions optimized for strength, weight, or aesthetics. This paves the way for innovative, customer-centered products.

How does parametric design enable scalability while maintaining individuality?

One major benefit is the ability to support mass customization through parametric modeling. This process combines the efficiency of mass production with the flexibility of custom design.

Businesses can manufacture products at scale while still meeting individual needs. For example, eyewear companies allow customers to select frames that fit their exact measurements, all enabled by parametric rules

Integrating Generative Design for Customizable Products

Another trend connected to parametric workflows is generative design for customizable products. This method uses computational processes to create design variations optimized for strength, efficiency, or aesthetics. When combined with parametric modeling, it helps businesses deliver highly personalized yet functional products. From bicycles to architectural elements, generative systems allow rapid exploration of possibilities.

Benefits of Parametric Design

Using parametric design in product development offers several advantages:

Flexibility: Products can be adapted quickly to meet different user needs.

Speed: Faster iterations reduce time and cost of development.

Sustainability: Efficient material use reduces waste.

Quality: Fewer errors occur since variations are built from tested parameters.

Challenges and Considerations

While powerful, parametric design in product development comes with challenges. Designers and engineers need to invest time in learning advanced tools. Data handling also becomes complex as variations grow. Striking the right balance between automated adjustments and creative vision is essential for successful outcomes.

Future Trends

Looking ahead, parametric design in product development is likely to become even more integrated with digital technologies. Real-time simulations, cloud-based collaboration, and immersive visualization will strengthen its role in customization. As industries expand into digital manufacturing and smart products, parametric processes will remain at the core of innovation.

Summing Up!

The demand for personalized products is only set to increase. With its ability to deliver efficiency, adaptability, and creativity, parametric design in product development stands out as a vital approach. By connecting methods such as mass customization through parametric modeling and generative design for customizable products, businesses can offer unique solutions without losing efficiency. The future of product design is not just about creating—it’s about creating with flexibility, and parametric methods make that possible.