The Lightweight Advantage: Exploring the Use of Titanium Sheet Metal in Aerospace and Medical Devices

Titanium is a unique metal known for being strong and light. It has become trendy in both the aerospace and medical fields. This blog will explain why titanium sheet metal is so valuable, focusing on its advantages and use in these two critical areas.

Why Titanium is Special

Titanium has some fantastic qualities that make it very useful. Here are the key reasons why it is so special:

Lightweight: Titanium is much lighter than other strong metals like steel. This makes it perfect for uses where weight matters a lot.

Strength: Even though it is light, titanium is solid. It can handle a lot of stress and pressure without breaking.

Corrosion Resistance: Titanium does not rust easily. This means it can last a long time, even in harsh conditions.

Biocompatibility: Titanium is safe to use inside the human body. The body does not reject it, making it ideal for medical implants.

Titanium in Aerospace

The aerospace industry needs materials that are both strong and light. Every extra pound of weight on an airplane or spacecraft can mean more fuel consumption and higher costs. Titanium sheet metal helps solve this problem.

Aircraft Parts: Many parts of airplanes are made from titanium sheet metal. This includes the wings, engines, and other structural parts. Because titanium is light, it helps improve fuel efficiency and allows planes to fly faster and farther.

Spacecraft: Spacecraft must be as light as possible to leave Earth's atmosphere and travel in space. Titanium's light weight and strength make it a perfect choice for building spacecraft parts. It helps spacecraft carry more equipment and perform better on missions.

Safety: Titanium is also very safe to use in aerospace. It can withstand extreme temperatures and does not rust easily. This means it helps keep aircraft and spacecraft safe and reliable.

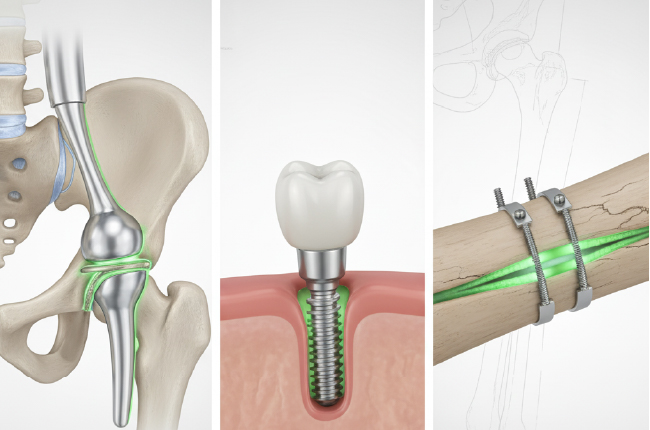

Titanium in Medical Devices

Titanium sheet metal also benefits the medical field significantly. It is used in many different medical devices and implants.

Implants: Titanium is often used to make implants like hip replacements, dental implants, and screws for broken bones. Its biocompatibility means the body does not reject it and bonds well with bone.

Surgical Instruments: Many surgical tools are made from titanium. These tools need to be strong, lightweight, and resistant to corrosion. Titanium meets all these requirements, making surgeries safer and more effective.

Prosthetics: Prosthetic limbs often use titanium parts because they are light and robust. This makes them more comfortable and durable for the people who use them.

The Process of Making Titanium Sheet Metal

Making titanium sheet metal involves several steps. The process starts with titanium ore, which is mined from the Earth. This ore is then processed to extract pure titanium. The titanium is melted and formed into large blocks. These blocks are rolled into thin sheets. These sheets can then be cut and shaped into the desired parts for aerospace and medical uses.

The Future of Titanium

The future looks bright for titanium. As technology advances, the demand for solid and lightweight materials will continue to grow. Titanium's unique properties make it a valuable resource for many industries. Research is ongoing to find new ways to use titanium and make it even more affordable.

Conclusion

Titanium sheet metal offers many advantages, making it indispensable in aerospace and medical devices. Its light weight, strength, corrosion resistance, and biocompatibility make it an excellent choice for these high-tech and life-saving applications. As technology advances, titanium's role will only grow, helping us reach new heights in aviation and improving health outcomes for countless people worldwide.

Titanium is a remarkable metal that has revolutionized the aerospace and medical fields. Its unique properties allow for the creation of safer, more efficient, and longer-lasting products. Whether helping a plane fly higher or improving someone's quality of life with a medical implant, titanium sheet metal represents the lightweight advantage.