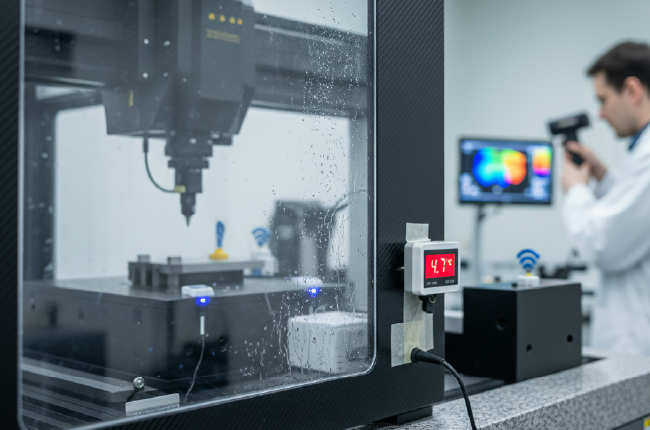

The Importance of Temperature Stability in CMM Operations

Precision is crucial in a Coordinate Measuring Machine (CMM) which guarantees that parts meet exact specifications. Achieving accurate results depends heavily on CMM temperature stability, as even minor fluctuations can affect the machine’s components and lead to measurement errors. Maintaining CMM thermal stability ensures consistent, reliable results, while proper environmental control helps protect equipment and improve repeatable precision measurement. This blog highlights how temperature affects CMM performance, the importance of a stable environment, practical methods to maintain CMM temperature stability, real-world benefits such as reduced defects and cost savings, and best practices operators can follow to achieve optimal machine performance.

Understanding Temperature Effects on CMMs

CMMs are made of materials like steel and granite. These materials expand or contract temperature changes. Even a small variation can cause the probe or base to shift slightly, affecting the accuracy.

For example, a 1°C change can lead to noticeable errors in high-precision components. This is why CMM temperature stability is critical for exact readings and consistent results.

Importance of Maintaining a Stable Environment

Maintaining a stable environment is critical for accurate and reliable CMM operations. Even minor temperature fluctuations can cause materials in the machine, such as granite or steel, to expand or contract. This affects probe positioning and can lead to measurement of errors.

Ensuring CMM temperature stability helps achieve precise and repeatable results, which is essential for quality control in manufacturing. Proper environmental control also extends the life of the machine by minimizing stress caused by thermal changes.

Key benefits of a stable environment include:

Consistent Measurements: Stable temperatures prevent thermal expansion, ensuring measurements are repeatable and reliable.

Reduced Errors: Controlling the environment minimizes deviations caused by temperature shifts.

Improved Product Quality: Accurate measurements help maintain tight tolerances and reduce defective parts.

Enhanced Confidence: Operators can trust measurement results when the environment is controlled.

Protection of Equipment: Maintaining the right temperature and humidity prevents wear and stress from the CMM.

Efficient Operations: Minimizing errors reduces rework and saves time and cost in production.

By prioritizing temperature stability and implementing environmental control measures such as air conditioning, insulation, and monitoring, manufacturers can ensure optimal CMM performance and precise measurement outcomes.

Methods to Ensure Temperature Stability

Maintaining CMM temperature stability requires careful attention to the machine’s environment and operational practices. Some effective methods include:

Place the CMM in a climate-controlled room: A dedicated room with stable temperature and minimal drafts prevents sudden thermal changes that can affect measurement accuracy.

Keep the room temperature consistent throughout the day: Avoid fluctuations by monitoring the temperature regularly and maintaining it within the recommended range for the CMM.

Use insulation or barriers around the machine if needed: Physical barriers or insulation to protect the CMM from external heat sources, sunlight, or nearby machinery that could alter the ambient temperature.

Regularly calibrate the machine: Even minor temperature variations can affect measurements. Frequent calibration ensures that the CMM remains accurate and reliable.

Implementing these methods not only protects the machine but also enhances precision measurement and overall product quality.

Real-World Benefits of Temperature Stability

Stable temperature conditions directly improve measurement reliability. When CMM thermal stability is maintained:

Measurements become consistent and repeatable.

Product defects decrease as parts are manufactured within strict tolerances.

Companies save time and costs by reducing rework and scrap.

Manufacturing processes run smoothly, improving overall efficiency and output.

The benefits extend beyond accuracy, influencing quality control, production efficiency, and customer satisfaction.

Best Practices for CMM Operators

Operators play a key role in maintaining CMM temperature stability. Effective practices include:

Monitoring room temperature and humidity regularly: This helps detect environmental changes early and allows corrective action.

Conducting measurements at the same time daily: Consistency in measurement timing avoids thermal variations caused by daily temperature shifts.

Following maintenance and calibration schedules: Regular upkeep ensures the machine compensates for any minor environmental effects and continues to provide precise results.

Even simple practices like these have a significant impact on achieving high-quality precision measurement and ensuring that the CMM performs at its best.

Conclusion

Temperature stability is essential for every CMM operation. It protects measurement accuracy, ensures consistent results, and improves overall product quality. By investing in CMM temperature stability and proper environmental control, manufacturers can achieve reliable results and reduce costly errors.