Surface Roughness Impact on Component Performance

In modern manufacturing, the tiniest details can make a big difference. One such detail is surface roughness, which refers to the small peaks, valleys, and irregularities on a part’s surface. While it may seem minor, surface roughness plays a key role in determining a component’s reliability, efficiency, and overall performance. From automotive engines to medical devices, controlling surface texture ensures that every part functions as intended. Poor surface finish can lead to excessive wear, poor assembly, and reduced lifespan, directly impacting component performance. On the other hand, a smooth and well-controlled surface improves durability, reduces friction, and enhances manufacturing quality. This blog explores the importance of surface roughness, how it affects component performance, and the methods manufacturers use to maintain high standards of manufacturing quality. By understanding these factors, engineers can make informed decisions to optimize parts for longevity, efficiency, and precision.

What is Surface Roughness?

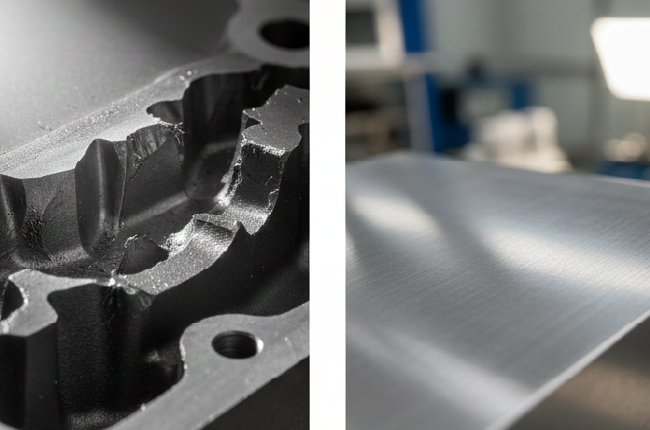

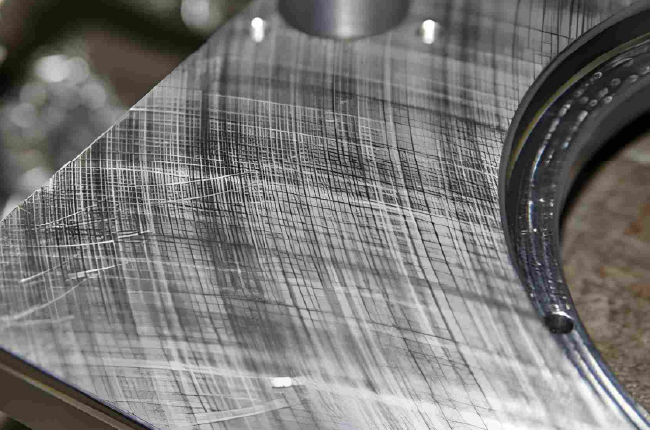

Surface roughness refers to the fine irregularities on a material’s surface caused by the manufacturing process. These tiny peaks and valleys can influence how parts interact with each other. Common parameters like Ra (average roughness) and Rz (maximum height of roughness) are used to measure surface finish. Synonyms like “surface texture” or “surface finish” are often used interchangeably. Measuring surface roughness accurately allows manufacturers to maintain component performance and predict how the part will behave under real conditions.

Factors Affecting Surface Roughness

Several factors can change the surface texture of a component:

Material Type: Hard materials often produce smoother surfaces, while softer materials can have uneven finishes.

Machining Processes: Turning, milling, and grinding each create different textures. The choice of process directly affects surface roughness.

Cutting Tools and Speed: Sharp tools reduce roughness, while worn tools increase it. Cutting speed and feed rate also play a role.

Lubrication and Cooling: Proper cooling reduces heat and tool wear, helping achieve a smoother surface.

Each of these factors influences how well a component will perform. Maintaining the right balance ensures high manufacturing quality and consistent results.

Surface Roughness and Component Performance

Surface roughness impacts a component in many ways:

Friction and Wear: A rough surface increases friction between parts, leading to faster wear. Smooth surfaces reduce energy loss and prevent early failure.

Fatigue Life and Durability: Peaks and valleys act as stress points. High surface roughness can reduce fatigue resistance and shorten lifespan.

Assembly and Fit: Parts with uneven surfaces may not fit together properly, affecting overall machine performance.

Thermal and Electrical Performance: In electronic and thermal components, surface finish affects heat transfer and conductivity.

Optimizing surface roughness improves component performance, reduces maintenance costs, and enhances efficiency.

Case Studies / Industry Examples

Automotive Components: Engine parts like camshafts and pistons require smooth surfaces to reduce friction and improve fuel efficiency.

Aerospace Parts: Aircraft components need precise surface finishes to withstand extreme loads and prevent fatigue.

Medical Devices: Implants and surgical tools rely on controlled surface texture for better performance and biocompatibility.

Electronics: Connectors and heat sinks benefit from controlled surface roughness to enhance conductivity and cooling.

These examples highlight how critical surface finish is in achieving optimal component performance.

Methods to Control Surface Roughness

Manufacturers use several techniques to manage surface roughness:

Precision Machining: Advanced CNC machines produce smooth surfaces consistently.

Polishing, Lapping, and Honing: These finishing processes refine surfaces to reduce roughness.

Coatings and Surface Treatments: Protective layers can smooth surfaces and prevent wear.

Inspection and Quality Control: Regular checks ensure surfaces meet specifications, supporting consistent manufacturing quality.

By implementing these methods, manufacturers can maintain high component performance across all production stages.

Benefits of Optimal Surface Roughness

Controlling surface roughness offers clear advantages:

Longer Component Life: Reduced friction and stress points increase durability.

Lower Maintenance Costs: Smooth parts wear slower, minimizing replacements.

Higher Efficiency: Less friction and better fit improve machine performance.

Consistent Manufacturing Quality: Reliable surface finishes lead to predictable, high-quality products.

Wrapping Up!

Surface roughness has a direct effect on how a component performs and the overall manufacturing quality. By understanding the factors that influence surface texture and implementing proper control methods, manufacturers can improve durability, efficiency, and precision. Optimizing surface roughness ensures that every part meets performance expectations, reducing downtime and cost.