Revolutionizing Automotive Manufacturing with Precision Sheet Metal Components

In today's world, cars are not just vehicles but a big part of our lives. They help us get to work, visit friends, and explore new places. But have you ever thought about how cars are made? One of the most essential parts of car making is using precision sheet metal components. These components are changing how cars are built, making the process faster, cheaper, and better.

Why is Precision Important?

In car manufacturing, every part needs to fit perfectly. If one part is slightly off, it can cause big problems. Precision sheet metal components ensure that every part fits just right. This precision helps in several ways:

Better Quality: When parts fit perfectly, the car runs better and lasts longer.

Faster Production: Accurate parts mean less time fixing mistakes and more time building cars.

Lower Costs: Precision reduces waste and saves money on materials.

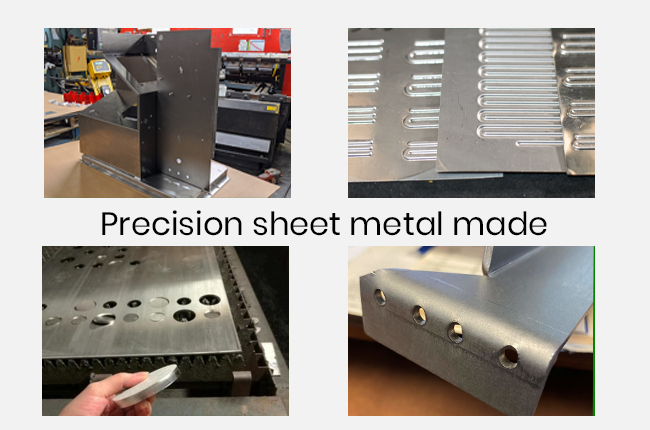

How is Precision Sheet Metal Made?

Making precision sheet metal components involves several steps:

Design: Engineers design the parts using computer software. This software allows them to create detailed plans and check for potential problems.

Cutting: Machines like lasers or water jets cut the metal into suitable shapes. These machines are controlled by computers, which ensures they cut with high accuracy.

Forming: The cut pieces are then shaped into final forms using presses and other tools. This step might include bending, folding, or stamping the metal.

Assembly: The formed pieces are combined to make more significant components, like car doors or hoods.

The Benefits for Car Manufacturers

Using precision sheet metal components offers many benefits for car manufacturers:

Flexibility: Precision sheet metal makes it easier to make design changes. If a new car model needs a different shape or size of part, it can be quickly produced.

Consistency: Every part made using precision techniques will be the same. This consistency is crucial for quality control.

Efficiency: Less material is wasted, and less time is spent fixing errors. This efficiency leads to faster production times.

Impact on the Automotive Industry

The use of precision sheet metal components is revolutionizing the automotive industry. Here's how:

Innovation: New car designs are possible because parts can be made with more complex shapes and better materials.

Sustainability: Using precision sheet metal helps reduce waste, which is better for the environment. It also allows for the use of lighter materials, making cars more fuel-efficient.

Safety: Cars made with precision parts are safer. The exact fit of parts means fewer defects and better performance in crash tests.

Final Thoughts!

Precision sheet metal components are changing the way cars are made. They offer better quality, faster production, and lower costs. This technology allows car manufacturers to be more flexible, consistent, and efficient. As a result, the automotive industry can innovate, improve sustainability, and enhance safety.

The next time you see a car on the road, think about the precision and technology that went into making it. These small, perfectly made parts make modern cars so reliable and advanced. Precision sheet metal components truly are revolutionizing automotive manufacturing.