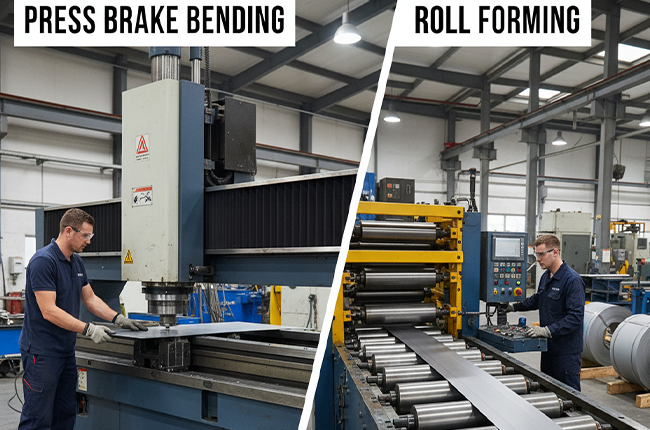

Press Brake Bending vs. Roll Forming

When it comes to metal fabrication, two processes often come into discussion — Press Brake Bending and Roll Forming. Both methods shape sheet metal into precise parts and structures, but they work in different ways and serve different purposes. Whether you’re manufacturing components for automotive, aerospace, or construction industries, choosing the right process can make a huge difference in cost, accuracy, and production time. Let’s break down the differences between Press Brake Bending and Roll Forming in simple terms and help you decide which one best fits your project needs.

What is Press Brake Bending?

Press Brake Bending is a metal forming process that uses a press brake machine to bend sheet metal into specific angles. The machine uses a punch and die setup to apply pressure, shaping the metal to the desired form.

This process is ideal for short-run productions and parts that require sharp bends or custom angles. It’s commonly used in manufacturing brackets, enclosures, frames, and panels.

Key advantages of Press Brake Bending:

Excellent for custom or small-batch production.

Offers high precision and tight tolerance.

Flexible for different materials and thicknesses.

Easier setup for prototyping and custom designs.

For example, if your project needs a few precise bends on thick aluminum sheets, Press Brake Bending would be the perfect choice.

What is Roll Forming?

Roll Forming is a continuous process where a long strip of sheet metal passes through a series of rollers that gradually bend it into the required shape. Unlike the press brake, which bends one section at a time, roll forming can create long, uniform profiles in one smooth operation.

This process is widely used for high-volume production of consistent parts such as roofing panels, channels, pipes, and structural sections.

Key advantages of Roll Forming:

Perfect for large-scale production.

Ensure uniformity and consistency in every piece.

Capable of handling long lengths of metal.

Reduces waste and overall production cost.

So, if you’re manufacturing thousands of identical metal sections, Roll Forming will save you time and money.

Press Brake Bending vs. Roll Forming

Let’s look at the key differences between Press Brake Bending and Roll Forming to help you make a clear decision.

| Factors | Press Brake Bending | Roll Forming |

| Production Volume | Ideal for low to medium production | Best for high-volume production |

| Bend Length | Limited by press brake size | Can form long continuous parts |

| Precision | High accuracy for complex bends | Consistent accuracy for simple shapes |

| Setup Time | Quick setup for small runs | Requires detailed setup and tooling |

| Cost Efficiency | Cost-effective for prototypes | Cost-effective for bulk manufacturing |

| Flexibility | Great for custom and varied designs | Best for repetitive, uniform shapes |

When to Choose Press Brake Bending

You should consider Press Brake Bending when your project involves:

Small or medium production runs.

Complex parts with multiple bends.

Prototyping or custom designs.

Thick materials that require high bending force.

This method gives you control and flexibility, which is ideal for manufacturers working on unique or intricate components.

When to Choose Roll Forming

Roll Forming is the best fit when you need:

Long, continuous metal profiles.

Large production volumes.

High consistency across all parts.

Cost-effective production for simple shapes.

It’s the go-to method for industries like construction, automotive, and appliance manufacturing, where thousands of identical parts are required with minimal variation.

How to Decide: Press Brake Bending or Roll Forming?

Your decision should depend on your project requirements, production goals, and budget.

If you need short runs, flexible designs, and high precision, go with Press Brake Bending.

If you’re focused on mass production and uniformity, choose Roll Forming.

Many companies also combine both methods. For example, Roll Forming can create the basic structure, while Press Brake Bending adds final adjustments or special features.

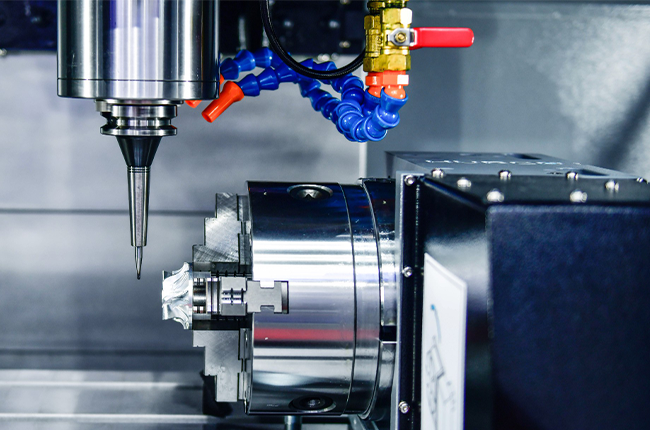

Benefits of Modern CNC Machines in Both Processes

Today’s advanced CNC technology has improved both Press Brake Bending and Roll Forming significantly. CNC-controlled systems allow for:

Faster production speeds.

Better accuracy and repeatability.

Reduced human error.

Automated setup and programming.

At VmakeU, we use state-of-the-art CNC press brakes and roll forming machines to deliver top-quality metal parts for global industries. Our team ensures that every component meets exact specifications, whether it’s a small prototype or a large production run.

Why Choose VmakeU for Press Brake Bending and Roll Forming Services

At VmakeU, we understand that every project is unique. That’s why we offer both Press Brake Bending and Roll Forming services under one roof.

Our experts analyze your design, volume, and material needs to recommend the most efficient and cost-effective fabrication method. With advanced machinery, strict quality control, and quick turnaround, we ensure your project meets global standards — every single time.

Final Thoughts

Both Press Brake Bending and Roll Forming are valuable metal forming methods, each serving specific applications. The best process depends on your design, material, and production volume.

If you want high precision for custom parts, go for Press Brake Bending.

If you want fast, consistent output for long metal sections, Roll Forming is your answer.

Whichever you choose, partnering with an experienced fabrication company like VmakeU ensures you get the best of both worlds — accuracy, efficiency, and reliability.