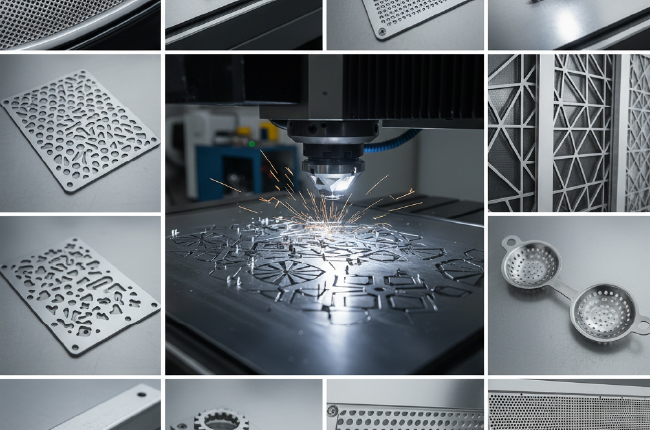

Precision Punching: Creating Complex Geometries with Minimal Waste

Precision punching plays a big role in producing high-quality metal parts quickly and accurately. Whether it’s for the aerospace, automotive, or construction industry, this process helps create complex metal geometries with minimal material waste. Unlike traditional cutting or drilling, precision punching uses a punch and die set to shape sheet metal into the desired design. It’s fast, cost-effective, and delivers consistent results — which makes it one of the most preferred methods in modern sheet metal fabrication.

What is Precision Punching?

Precision punching is a process where a machine presses a punch through a sheet of metal to create holes, shapes, or patterns. The die beneath the sheet determines the exact geometry. This process can form anything from small holes to intricate cutouts — all with high accuracy.

Thanks to advanced CNC punching machines, fabricators can now design complex parts that meet tight tolerances and international quality standards. The result? Perfectly punched metal components that fit right into assemblies with little to no rework.

The Importance of Precision in Metal Punching

When you’re producing parts for industries like aerospace, electronics, or automotive, every millimeter counts. Even a small deviation can affect the performance of the final product.

That’s where precision punching stands out. It ensures uniformity across every piece — whether you need 10 units or 10,000. Precision also helps minimize waste, saving both raw materials and production costs.

In short, precision punching combines accuracy, speed, and sustainability, which are essential for global manufacturing standards.

Creating Complex Geometries with Precision Punching

One of the biggest strengths of precision metal punching is its ability to create complex geometries that might be difficult or expensive with other methods.

Using modern CNC punch presses, fabricators can create designs with varying hole sizes, slots, embossing, louvers, or even custom patterns. The software-controlled process ensures that every punch hits exactly where it should — down to fractions of a millimeter.

So, whether it’s a high-performance automotive panel or a delicate electronic component, precision punching can handle it with ease.

Precision Punching and Minimal Material Waste

Sustainability is now a global priority. Industries are always looking for ways to reduce material waste without compromising quality. Precision punching helps achieve exactly that.

Because of its optimized tool paths and efficient layout programming, precision punching makes the most out of every metal sheet. The process ensures maximum material utilization by minimizing scrap and rework.

This not only saves money but also supports eco-friendly manufacturing — a key factor for global clients who value sustainability in their supply chain.

Advantages of Precision Punching in Metal Fabrication

Let’s look at some of the main advantages that make precision punching a preferred choice in the metal fabrication industry:

1. High Accuracy and Consistency

Every part produced through precision punching has identical dimensions. This accuracy ensures easy assembly and reduces chances of error.

2. Cost-Effective Production

Since it reduces material waste and production time, precision punching lowers overall manufacturing costs.

3. Fast and Efficient Process

Modern CNC punch presses work at high speed, producing hundreds of parts per hour while maintaining precision.

4. Design Flexibility

From simple shapes to complex patterns, precision punching allows for endless design possibilities.

5. Suitable for Different Metals

This process works well with various materials such as stainless steel, aluminum, copper, and mild steel—offering flexibility across industries.

Applications of Precision Punching Across Industries

The use of precision punching extends across multiple industries worldwide. Here are some common applications:

Aerospace: For lightweight and complex components with tight tolerances.

Automotive: For body panels, brackets, and functional metal parts.

Electronics: For enclosures, connectors, and intricate sheet parts.

Construction: For perforated panels, ceiling grids, and architectural elements.

Appliances: For high-precision, repeatable metal parts used in daily equipment.

In each of these sectors, precision punching ensures a balance of durability, design, and dimensional accuracy.

Precision Punching vs. Other Fabrication Techniques

Compared to processes like laser cutting or plasma cutting, precision punching offers a unique combination of speed, cost-effectiveness, and tooling flexibility.

While laser cutting is ideal for detailed profiles, punching is faster for repetitive shapes and large batch production. Additionally, punching can form embosses, countersinks, and louvers — something laser machines cannot do directly.

That’s why many manufacturers combine CNC punching with other fabrication methods for best results — achieving precision and productivity together.

Why Choose VmakeU for Precision Punching Services

At VmakeU, we specialize in high-precision sheet metal punching for global industries like aerospace, automotive, oil and gas, and renewable energy. Our state-of-the-art CNC machines and skilled technicians ensure that every part meets international standards for quality and accuracy.

Whether you need custom metal components, prototype development, or mass production, VmakeU provides end-to-end fabrication services that guarantee excellence with minimal waste.

We focus on innovation, speed, and sustainability, helping clients across the world achieve better results in less time.

Conclusion

In today’s competitive world, efficiency, precision, and sustainability go hand in hand. Precision punching perfectly fits this approach by delivering complex designs, minimal material waste, and consistent quality.

As industries continue to evolve, the demand for reliable and sustainable fabrication processes will only grow. Partnering with an experienced manufacturer like VmakeU ensures that your metal components meet the highest global standards — efficiently and economically.