Precision Machining vs. Conventional Machining: Understanding the Differences

When it comes to making parts and products, machining is a crucial process. It involves cutting, shaping, and finishing materials, typically metal or plastic, into specific forms and sizes. There are two main types of machining: precision machining and conventional machining. Both methods have their own unique characteristics and advantages. Understanding the differences between them can help in choosing the right process for your needs.

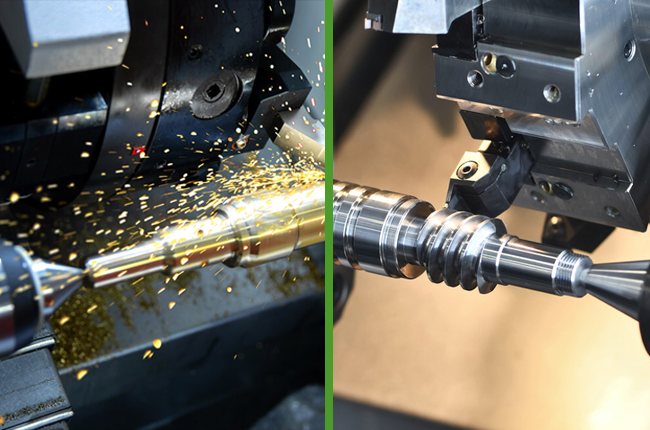

What is Conventional Machining?

Conventional machining is the traditional method of machining. It includes processes like turning, milling, drilling, and grinding. These processes use manual or semi-automatic machines to remove material from a workpiece to create the desired shape. The main tools used in conventional machining are:

Lathes: Used for turning operations where the workpiece rotates, and the cutting tool moves along its surface.

Milling Machines: Used for cutting solid materials into precise shapes and sizes using rotary cutters.

Drill Presses: Used to create round holes in a workpiece using a rotating drill bit.

Grinders: Used for finishing surfaces by removing small amounts of material.

In conventional machines, accuracy and precision depend heavily on the skill of the operator. The machines are manually controlled, so the operator must be experienced to achieve the desired results. Conventional machining is often used for simpler tasks and for producing parts in lower quantities.

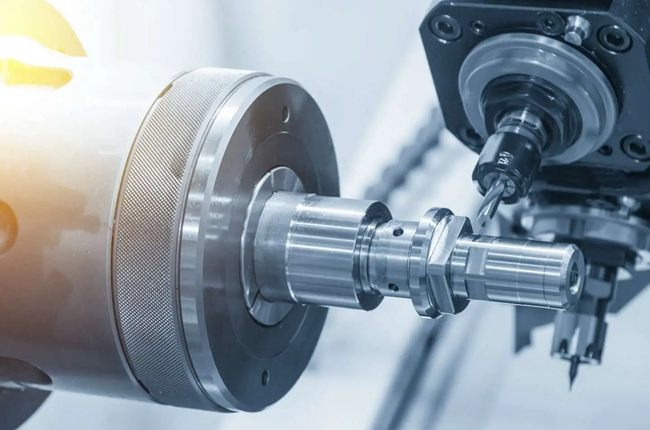

What is Precision Machining?

Precision machining, on the other hand, uses advanced technology to achieve extremely high levels of accuracy and detail. It involves the use of computer numerical control (CNC) machines, which are automated and programmed to follow exact specifications.

The main types of precision machining tools include:

CNC Lathes: Like traditional lathes but computer-controlled for higher accuracy.

CNC Milling Machines: Automated milling machines that follow programmed instructions to create complex shapes.

CNC Routers: Used for cutting various materials like wood, plastics, and metals with high precision.

Electrical Discharge Machines (EDM): Use electrical sparks to shape hard materials that are difficult to machine with traditional methods.

Precision machining allows production of highly complex and intricate parts with tight tolerances. This means the parts are made to exact measurements with very little margin for error. It is ideal for industries that require high precision, such as aerospace, medical, and automotive industries.

Key Differences Between Precision and Conventional Machining

Accuracy and Precision

Conventional Machining: Relies on the operator's skill and experience. Achieving high precision can be challenging, especially for complex parts.

Precision Machining: Uses CNC technology to achieve extremely high precision and repeatability. Parts are produced exactly to specifications every time.

Complexity of Parts

Conventional Machining: Suitable for simpler, less complex parts. Complex shapes and tight tolerances are harder to achieve.

Precision Machining: Ideal for complex and intricate parts. CNC machines can create detailed and complex shapes with ease.

Production Volume

Conventional Machining: More suitable for low to medium production volumes. Manual operation can be time-consuming and less efficient for large quantities.

Precision Machining: Efficient for both low and high production volumes. Once a CNC machine is programmed, it can produce large quantities of parts quickly and consistently.

Cost

Conventional Machining: Generally, it has lower initial costs since it uses simpler machinery. However, labor costs can be higher due to manual operation.

Precision Machining: Higher initial investment due to the cost of CNC machines and programming. However, it can be more cost-effective in the long run for high-precision and high-volume production.

Flexibility

Conventional Machining: Provides flexibility in terms of adjusting the process manually. Operators can make quick adjustments on the fly.

Precision Machining: Requires programming changes to adjust the process, which can be time-consuming but ensures consistent results.

Wrapping Up!

Both precision machining and conventional machining have their own strengths and applications. Conventional machines are suitable for simpler tasks and smaller production runs where manual adjustments and operator skills are key.

Precision machining, with its advanced CNC technology, is ideal for producing complex, high-precision parts in larger volumes with consistent quality.

Understanding these differences helps in selecting the right machining process based on the specific needs of the project, ensuring efficiency, accuracy, and cost-effectiveness.