Precision Bus Bar Fabrication: Powering Reliable Electrical Systems

Bus Bar Fabrication plays a crucial role in ensuring smooth and efficient electrical performance. A bus bar is more than just a metal strip—it’s the backbone of a safe and stable current distribution. Whether it’s in data centers, power plants, or electric vehicles, precision-made bus bars ensure minimal energy loss and maximum durability. With growing demand for compact and high-performance Electrical Power Distribution Systems, the need for accuracy and innovation in Custom Bus Bar Manufacturing has never been higher. Precision fabrication techniques not only improve system efficiency but also guarantee long-term safety and reliability. This blog explores how advanced fabrication methods are powering the future of dependable electrical systems.

What Is Bus Bar Fabrication?

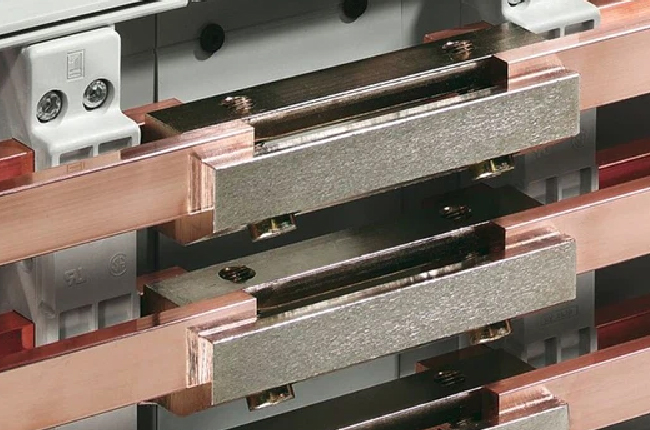

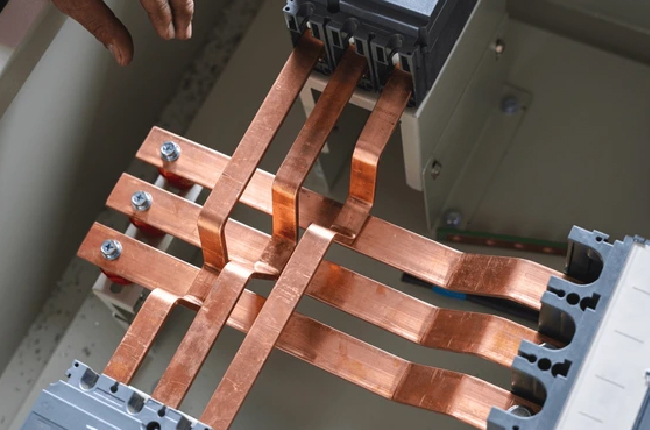

Bus Bar Fabrication is the process of designing and shaping conductive bars that distribute electricity in power systems. These bars are typically made from copper or aluminum due to their high conductivity. The process involves cutting, bending, punching, and plating to meet exact dimensions. When done precisely, it ensures a seamless flow of electricity with minimal energy loss.

The Importance of Precision in Bus Bar Manufacturing

Precision is not just a feature—it’s a necessity. A perfectly fabricated bus bar improves contact, reduces resistance, and ensures safety in the entire system. Even a slight error can lead to overheating or power failure. That’s why manufacturers rely on advanced techniques to achieve accuracy at every stage of Bus Bar Fabrication.

Types of Bus Bars and Their Applications

Bus bars come in various forms—flat, laminated, and flexible. Flat bus bars are common in switchboards and control panels. Laminated types are ideal for compact setups where space and vibration are concerned. Flexible bus bars serve vehicles and renewable energy systems, where movement or heat expansion occurs. Each type supports efficient Electrical Power Distribution Systems in its own way.

Advanced Techniques in Custom Bus Bar Fabrication

Modern technology has revolutionized Custom Bus Bar Manufacturing, making production faster, more accurate, and more reliable. Below are the key advanced techniques that ensure precision and efficiency in every step.

1. CNC Machining

CNC (Computer Numerical Control) machines use programmed commands to cut and shape bus bars with extreme accuracy. This eliminates manual errors and ensures consistent dimensions across large batches. CNC machining allows complex designs and tight tolerances, making it ideal for modern electrical systems.2. Laser Cutting

Laser Cutting uses high-energy beams to slice through copper or aluminum sheets with clean, burr-free edges. It offers superior precision compared to traditional cutting methods and reduces material waste. This process also allows for intricate patterns or hole placements without damaging the surface.3. Automated Bending

Automated bending machines ensure each bus bar is formed to the exact required angle. The process uses servo-controlled arms and programmable settings for consistent bends. This technique improves fitment in electrical assemblies and reduces mechanical stress during installation.4. 3D CAD Design and Simulation

Before fabrication begins, engineers use 3D CAD software to design and simulate the bus bar’s performance. This helps identify potential issues in fit, clearance, or heat dissipation. Virtual modeling saves time, minimizes rework, and ensures the final product integrates perfectly into Electrical Power Distribution Systems.5. Plating and Surface Treatment

Precision Bus Bar Fabrication often includes surface finishing such as tin, nickel, or silver plating. These coatings improve conductivity, prevent oxidation, and enhance corrosion resistance. A smooth surface finish also ensures better contact with connectors and terminals.6. Automated Inspection and Quality Control

Advanced vision systems and sensors inspect every piece for dimensional accuracy and defects. Automated inspection ensures consistent quality and compliance with strict industry standards, giving confidence in the final product’s reliability.

Quality Control and Testing

Every piece undergoes strict testing before using it. Measurements, conductivity checks, and thermal tests ensure the bar meets performance standards. With meticulous inspection, Bus Bar Fabrication delivers consistent results—ready to handle high loads safely and efficiently.

Advantages of Precision Bus Bar Fabrication

Accurate fabrication boosts efficiency, minimizes heat loss, and extends the lifespan of electrical systems. It simplifies wiring, reduces space requirements, and enhances safety. In Electrical Power Distribution Systems, precision-built bus bars mean fewer faults and higher uptime. Partnering with experts in Custom Bus Bar Manufacturing guarantees performance you can trust.

Wrapping Up!

Bus Bar Fabrication is more than just a process—it’s the foundation of reliable power delivery. With precision techniques and strict quality standards, manufacturers ensure stable and efficient operations. Investing expert fabrication means investing in safer, stronger, and smarter electrical systems.