Powder Coating vs. Paint: Why Powder Coating Is the Smarter Industrial Choice

The debate of Powder Coating vs Paint has long shaped the finishing industry. Both protect metal surfaces, but powder coating stands out for its strength, durability, and eco-friendliness. From machinery to consumer goods, industries now prefer powder coating for a cleaner, longer lasting, and more reliable surface finish. Explore here in this blog the difference between Powder Coating vs Paint. Learn why powder coating gives better durability, finish quality, and value for industrial applications.

What Is Powder Coating?

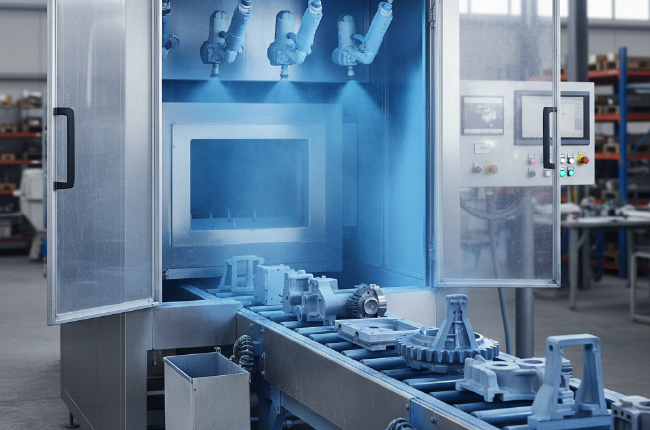

Powder coating is a dry finishing process where colored powder is electrostatically sprayed on metal and cured under heat. The result is a smooth, hard finish that resists wear and corrosion. It is commonly used in Industrial Powder Coating for machinery, vehicles, and appliances.

What Is Paint?

Paint, on the other hand, is a liquid coating applied using brushes or sprayers. It contains solvents and requires drying time. While easy to apply, it’s more prone to chips, scratches, and fading over time.

Key Differences Between Powder Coating and Paint

The real difference between Powder Coating vs Paint lies in performance. Powder coatings are thicker, more durable, and environmentally safer. Paint often fades or peels, especially under heat or moisture. Powder coating provides consistent color, resists corrosion, and eliminates the drips or streaks common in paint finishes.

| Feature | Powder Coating | Paint |

| Durability | High | Moderate |

| Finish | Even and smooth | Can drip or streak |

| VOCs | None | High |

| Maintenance | Minimal | Frequent |

Advantages of Powder Coating in Industrial Use

One of the major Powder Coating Benefits is its exceptional durability. It withstands scratches, impacts, and extreme weather better than paint. It also creates a uniform finish that doesn’t fade easily. In Industrial Powder Coating, these traits reduce maintenance costs and extend equipment life. Over time, this means fewer touch-ups and replacements.

• Enhanced Durability

Powder coating forms a hard, protective layer that resists chipping, peeling, and corrosion better than traditional paint.

• Consistent and Attractive Finish

The coating spreads evenly, leaving no brush marks or drips, resulting in a smooth, long-lasting surface.

• Weather and Chemical Resistance

Ideal for harsh environments, it protects metal parts from UV rays, chemicals, and moisture damage.

• Cost Efficiency Over Time

Though the initial setup may cost slightly more, reduced maintenance and longer lifespan save money in the long run.

• Eco-Friendly Process

Powder coating emits no harmful VOCs, making it safer for workers and the environment.

• Wide Range of Colors and Textures

From matte to gloss, metallic to texture, powder coating offers more variety and design flexibility.

Environmental and Safety Benefits

When comparing Powder Coating vs Paint, sustainability is a major win for powder coating. The process produces almost zero waste, as any overspray can be collected and reused. It also releases no toxic emissions or harmful gases into the air, making it far more eco-friendly than traditional paint.

Another big plus is worker safety. Since powder coating does not use solvents or volatile organic compounds (VOCs), it greatly reduces health risks on the shop floor. The air remains cleaner, and there’s no need for complex ventilation systems. Paint, on the other hand, often contains harsh chemicals that can cause irritation or respiratory issues and must be handled with extreme care. Its waste materials also require special disposal, which adds to cost and environmental strain.

In short, powder coating supports a greener and safer workplace while minimizing pollution and waste — something every modern manufacturer values.

Applications Across Industries

Industrial Powder Coating is incredibly versatile, making it the preferred choice in many fields.

Automotive and Machinery: Parts like wheels, frames, and machine housing are powder coated for strength and corrosion resistance. The coating helps them endure heat, moisture, and road debris without losing shine or protection.

Building and Architecture: Railings, window frames, and metal panels use powder coating to withstand outdoor exposure and maintain color for years.

Consumer Products: Everyday items like refrigerators, furniture, gym equipment, and lighting fixtures use powder coating for a stylish look and tough protection.

Its flexibility, variety of finishes, and durability make powder coating the go-to finishing solution for both industrial and consumer products.

When Paint Still Has Its Place

While powder coating outperforms paint in most areas, traditional paint still has its uses. Paint is easier for on-site touch-ups or coating parts that are too large or heat-sensitive to fit in a curing oven. For example, some construction or repair projects still rely on paint for convenience and mobility.

However, for factory-based production where precision, quality, and durability matter most, powder coating remains the superior option. It offers stronger protection and a more professional appearance that paint simply can’t match.

Final Words!

After examining Powder Coating vs Paint, it’s clear that powder coating is the more advanced and reliable finish. It delivers excellent protection against corrosion, scratches, and fading while offering a smoother and more attractive look. The process is clean, safe, and environmentally responsible, making it ideal for modern industry standards.

Although paint still serves limited purposes, powder coating provides unmatched longevity and value. Its combination of beauty, strength, and sustainability makes it the smarter choice for anyone seeking a durable and professional finish.