Overcoming Common Challenges in Machining: Tips and Techniques for Success

Machining is a process where we shape metal or other materials by cutting, drilling, or grinding. It's a crucial part of manufacturing, used to make everything from car parts to tools and everyday objects. But machining can be tricky. There are many challenges that machinists face. Here are some common problems and tips on how to overcome them.

Tool Wear and Tear

Problem: Tools used in machines wear out over time. This wear can cause poor-quality cuts and slow down the work.

Solution: Use high-quality tools made from durable materials. Regularly inspect tools for signs of wear and replace them when needed. Also, use proper cutting speeds and feeds to reduce the stress on tools. Keeping tools sharp is essential, so make sure to sharpen them regularly or replace them as soon as they start to dull.

Heat Buildup

Problem: Machining generates a lot of heat. This heat can damage both the tool and the material being worked on.

Solution: Use coolants and lubricants to keep temperatures down. These fluids help to carry away heat and reduce friction. It's also important to control the cutting speed and feed rate. Slower speeds can reduce heat buildup. Another technique is to use tools with coatings that help dissipate heat, such as titanium nitride (TiN) coatings.

Material Hardness

Problem: Some materials are very hard to machine. This can cause tools to wear out quickly and make it difficult to get a good finish.

Solution: Choose the right tool for the material. For example, use carbide tools for very hard materials. You can also use specialized cutting fluids designed for tough materials. Additionally, preheating the material can sometimes make it easier to machine.

Surface Finish

Problem: Achieving a smooth surface finish can be difficult, especially with hard materials or worn tools.

Solution: Use a fine, sharp tool and make light cuts. Ensure that the machine is stable and free from vibrations, as these can affect the surface finish. Using the correct cutting speed and feed rate is also crucial. Sometimes, using a finishing pass with a very sharp tool at a slow speed can help achieve a better finish.

Chip Control

Problem: During machining, the material being cut away forms' chips. These chips can clog the tool and interfere with the cutting process.

Solution: Use tools with chip breakers to control the size and shape of the chips. Properly directing the flow of coolant can also help wash away chips from the cutting area. Regularly clearing chips from the workspace is important to prevent them from causing problems.

Machine Calibration

Problem: Machines can go out of calibration over time, leading to inaccurate cuts and measurements.

Solution: Regularly check and calibrate your machines. Use precision instruments to measure and ensure that everything is set correctly. Keeping a maintenance log can help track when the machine was last calibrated and when it might need to be checked again.

Material Movement

Problem: Materials can move or shift during machining, leading to errors and poor-quality cuts.

Solution: Secure the material firmly in place using clamps or fixtures. Make sure that the workpiece is stable and cannot move during the cutting process. Using a vise or a fixture that is designed for the specific shape and size of the material can help keep it secure.

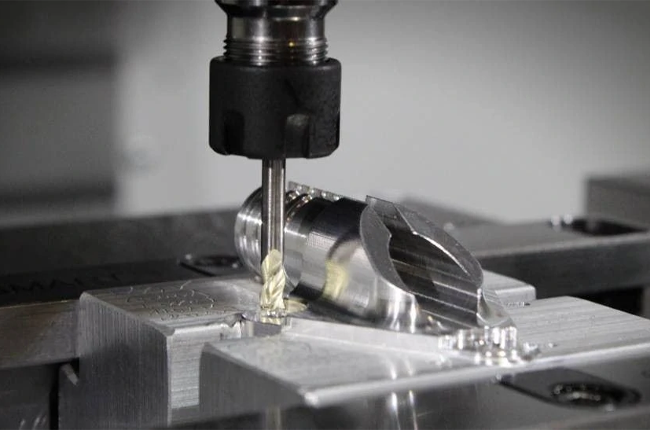

Programming Errors (CNC Machining)

Problem: In CNC machining, programming errors can lead to incorrect cuts or machine damage.

Solution: Double-check all programs before running them. Simulate the machining process using software to catch errors before they happen on the machine. It's also helpful to start with a slower feed rate and closely monitor the first few runs of a new program to ensure everything is correct.

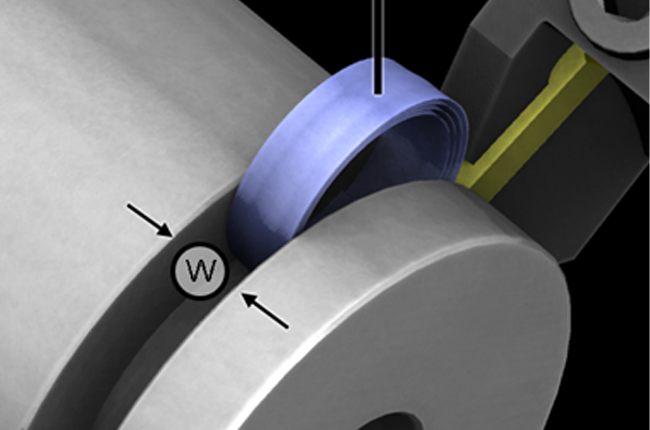

Vibration and Chatter

Problem: Vibration and chatter can occur during machining, leading to poor surface finish and tool wear.

Solution: Reduce the cutting speed and increase the feed rate to find a balance that minimizes vibration. Use tools with a larger diameter or a different geometry that can help absorb vibrations. Ensuring that the machine and workpiece are rigidly supported can also help reduce chatter.

Operator Skill

Problem: The skill level of the operator can greatly affect the machining process.

Solution: Provide proper training and education for machinists. Encourage continuous learning and staying updated with the latest techniques and technologies. Experienced operators can troubleshoot problems more effectively and improve the machining process.

Conclusion

Machining is a complex and challenging field, but by understanding and addressing common problems, machinists can improve the quality and efficiency of their work.

Using the right tools, maintaining proper speeds, and ensuring machine accuracy are key to overcoming these challenges. With these tips and techniques, you can achieve success in your machining projects.