Non-Contact Measurement: How VMM Protects Delicate Components

Non-contact measurement has transformed the way industries inspect sensitive parts. This is especially important for fragile or intricate parts where even slight pressure can cause damage. Video Measuring Machines (VMMs) make non-contact measurement reliable, fast, and precise, ensuring delicate components stay intact during inspection. This blog highlights how non-contact measurement is transforming the inspection of sensitive parts. You’ll learn how VMM (Video Measuring Machines) make measurements faster, more precise, and safer, especially for delicate component inspection. We will explain what a VMM is, the advantages of non-contact methods, how these machines work step by step, and their applications in industries like electronics, medical devices, and aerospace. By the end, you’ll understand why non-contact measurement is essential for protecting fragile components while ensuring accurate results.

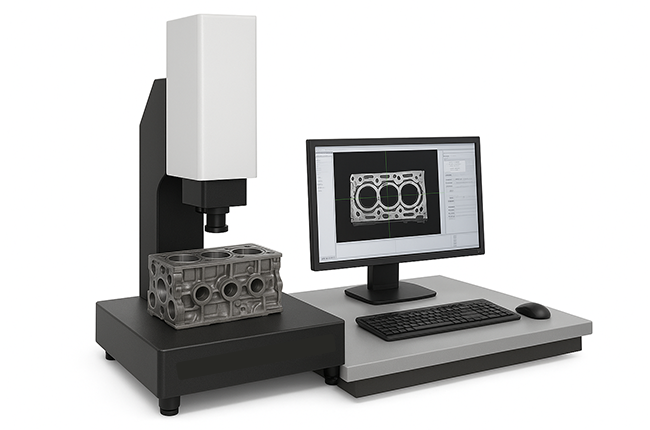

What is a VMM?

A VMM, or Video Measuring Machine, is a tool that captures precise dimensions of parts using cameras and optics. It does not rely on tactile probes, which can scratch or deform soft materials. Unlike traditional measurement tools, a VMM combines high-resolution imaging with intelligent software to map component surfaces accurately.

Advantages of Non-Contact Measurement for Delicate Components

The biggest benefit of non-contact measurement is safety for the part. Delicate component inspection becomes easier because there’s no risk of physical damage. This approach also reduces tool wear and maintenance costs. Since measurements are optical or laser-based, even complex geometries and micro-sized features can be captured precisely.

Other advantages include:

Faster measurement cycles, which improve production efficiency.

Reduced errors caused by part deformation during measurement.

Consistency and repeatability in quality control processes.

How VMM Works

The process of using a VMM (Video Measuring Machine) for non-contact measurement is precise, efficient, and designed to protect delicate components. Instead of touching the part, the machine uses light, optics, and software to capture accurate dimensions.

The following steps explain exactly how a VMM measures components safely and effectively:

Step 1: Project Light onto the Component

The VMM directs a focused light onto the part. This highlights the edges and surface details without touching them.

Step 2: Capture High-Precision Images

High-resolution cameras capture detailed images of the component from multiple angles.

Step 3: Analyze Images with Software

Specialized software processes the images to calculate accurate dimensions.

Step 4: Measure Key Parameters

The VMM measures height, width, depth, angles, and other critical features without any physical contact.

Step 5: Zoom for Detailed Inspection

Operators can zoom in on small or complex areas to intricate features closely.

Step 6: Safe Measurement of Delicate Components

This ensures fragile parts in electronics, medical devices, and aerospace industries are measured accurately without damage.

Applications in Industry

Non-contact measurement with VMM is widely used in industries where precision and part integrity are critical, Such as:

Electronics: Measures tiny circuit boards accurately without bending, scratching, or damaging delicate components.

Medical Device Manufacturing: Prevents contamination and preserves fragile parts during inspection.

Automotive Industry: Ensures precise dimensions of components while maintaining part integrity.

Aerospace Industry: Provides accurate measurement for critical parts without causing damage.

Final Thoughts

Non-contact measurement has become essential for industries that handle delicate components. VMM technology allows for accurate and efficient inspection while protecting parts from damage. By adopting these tools, manufacturers can maintain quality, reduce waste, and improve productivity. Delicate component inspection has never been safer or more reliable.