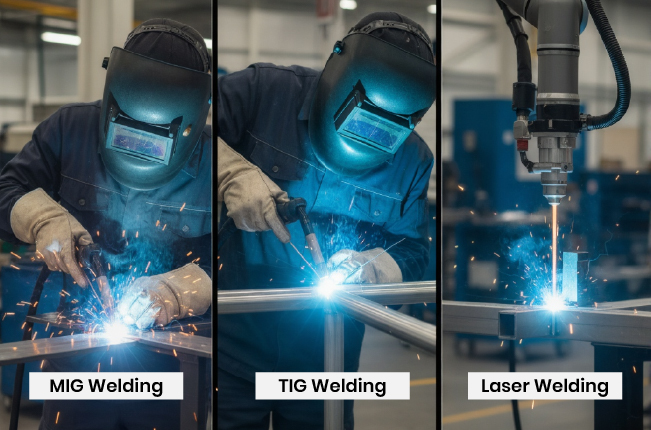

MIG, TIG, and Laser Welding: Understanding the Best Fit

When it comes to metal fabrication, choosing the right welding process is one of the most important decisions you can make. Whether you are working on aerospace components, automotive parts, or industrial machinery, the welding method you choose will directly affect the quality, strength, and appearance of the final product. Among the most popular and advanced methods today are MIG welding, TIG welding, and Laser welding. Each has its unique benefits, challenges, and ideal applications. In this blog, let’s understand these three techniques in simple terms and find out which welding process best fits your manufacturing needs.

Understanding MIG Welding: The Go-To for Speed and Efficiency

MIG welding, or Metal Inert Gas welding, is one of the most widely used welding techniques across industries. It’s known for being fast, efficient, and suitable for both thin and thick metals.

In MIG welding, a wire electrode is continuously fed through a welding gun, while a shielding gas (usually argon or a mix of argon and carbon dioxide) protects the weld from contamination. This makes the process smooth and stable.

Why MIG Welding is Popular

It’s faster than other manual welding methods.

It works well with a variety of metals such as stainless steel, aluminum, and mild steel.

It’s easier to automate, making it ideal for large-scale production.

It produces minimal slag, reducing post-weld cleanup.

Best Applications for MIG Welding

MIG welding is commonly used in automotive manufacturing, construction, metal furniture, and sheet metal fabrication. For companies that need high productivity and strong welds at lower costs, MIG welding is a great choice.

Exploring TIG Welding: Precision and Quality at Its Best

TIG welding, also known as Tungsten Inert Gas welding, is all about precision and quality. Unlike MIG, TIG welding uses a non-consumable tungsten electrode, and the filler material is added manually if needed.

This technique requires more skill and patience, but the results are worth it. TIG welding creates clean, precise, and high-quality welds that are free from splatter and distortion.

Why TIG Welding Stands Out

It offers greater control over the weld.

Ideal for thin metals and intricate parts.

Produces beautiful, clean weld beads — perfect for visible joints.

No need for flux or excessive finishing.

Best Applications for TIG Welding

You’ll find TIG welding often used in aerospace, automotive, medical equipment, and artistic metalwork. It’s perfect when appearance and accuracy matter more than speed.

If your project demands strong, corrosion-resistant, and aesthetically pleasing welds, TIG welding is your best fit.

Laser Welding: The Future of Precision Welding

Laser welding represents the cutting edge of welding technology. It uses a focused laser beam to melt and fuse materials together with unmatched accuracy and minimal heat distortion.

This method is incredibly fast and can be easily automated, which makes it a perfect match for industries that demand high precision and consistent quality.

Why Laser Welding is Revolutionizing the Industry

Extremely precise and clean welds.

Minimal heat input and distortion.

High speed operation is suitable for automation.

Works with a variety of metals, including titanium and aluminum.

Ideal for micro-welding and complex designs.

Best Applications for Laser Welding

Laser Welding is widely used in aerospace, electronics, medical devices, and automotive manufacturing. It’s perfect for companies that prioritize efficiency, consistency, and innovation in production.

MIG vs TIG vs Laser Welding: Which One is the Best Fit?

Choosing the right welding process depends on what you’re trying to achieve. Each method has its own strengths, so understanding your project’s goals is key.

| Feature | MIG Welding | TIG Welding | Laser Welding |

| Speed | High | Moderate | Very High |

| Precision | Good | Excellent | Superior |

| Automation | Easy | Moderate | Fully compatible |

| Appearance | Clean | Excellent | Perfect |

| Cost | Low | Moderate | High |

| Applications | Large production, automotive, fabrication | Aerospace, decorative, high-end manufacturing | Electronics, aerospace, medical, micro parts |

If you’re working on large production runs where speed and cost-efficiency matter, MIG welding is the right choice.

If your project requires fine control, quality, and clean aesthetics, TIG welding is your go-to.

And if your business is moving toward advanced, high-precision manufacturing, Laser welding will give you the edge you need.

How to Choose the Right Welding Process for Your Business

When selecting between MIG, TIG, and Laser welding, consider:

The type of metal you’re working with.

The required strength and precision of the weld.

Your production volume and budget.

The level of automation your facility supports.

Sometimes, a combination of processes can offer the best results. For example, MIG may be used for structural components, while TIG or Laser welding handles precision parts.

The key is to partner with a trusted metal fabrication company that understands your goals and helps you select the most effective technique.

Conclusion

Whether it’s MIG welding for speed, TIG welding for beauty and control, or Laser welding for advanced precision, each method plays a vital role in modern manufacturing.

At VmakeU, we combine cutting-edge welding technologies with expert craftsmanship to deliver custom metal fabrication solutions that meet global standards. Our team ensures that every project — big or small — is handled with precision, reliability, and a focus on quality.

If you’re looking for expert welding and fabrication services for your next project, VmakeU is here to help.

Partner with VmakeU today to explore the best welding solutions for your business.