Manual vs. Semi-Automatic Measuring Systems: Which Is Right for You?

Choosing the right measurement system can make or break your workflow. Manual vs Semi-Automatic Measuring Systems offer distinct advantages depending on your accuracy needs, production volume, and budget. Manual tools provide hands-on control, affordability, and flexibility for small-scale or precision tasks. On the other hand, semi-automatic systems deliver faster, more consistent results with less operator effort, making them ideal for high-volume or repeatable measurements. Understanding the differences between these systems helps you select the right tool for your operations. This guide explores both options, compares their features, and helps you decide which system suits your needs best.

What Are Manual Measuring Systems?

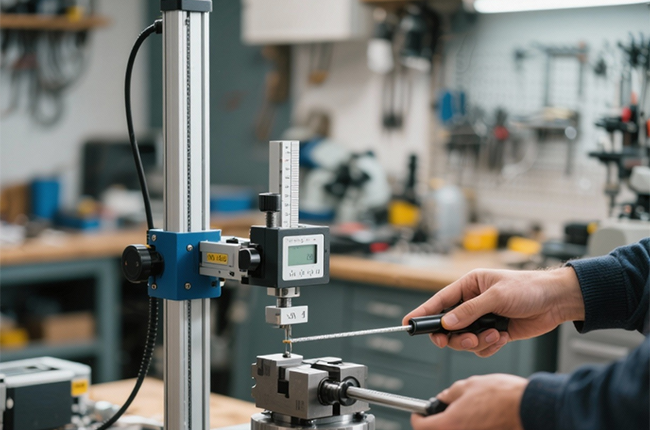

Manual measuring systems include tools like calipers, micrometers, and height gauges. These systems rely on the operator’s skill to take accurate readings.

Advantages:

Affordable and easy to maintain

High control over each measurement

Simple to use in low-volume tasks

Limitations:

Slower process compared to semi-automatic tools

Greater chance of human error

Not ideal for high-volume production

Manual systems are ideal for workshops that prioritize precision over speed.

What Are Semi-Automatic Measuring Systems?

Semi-automatic measuring systems combine manual input with automated functions. Examples include digital height gauges and automated micrometers.

Advantages:

Faster measurements with consistent results

Reduces operator fatigue

Easier to integrate with data systems

Limitations:

Higher initial cost

Requires operator training

More complex maintenance

These systems work best for environments that need speed and repeatable accuracy.

Key Factors to Consider When Choosing a Measuring System

Choosing the right measuring system depends on several practical factors that affect accuracy, efficiency, and cost.

Accuracy requirements: If your tasks demand high precision, semi-automatic systems reduce human error and deliver consistent results. Manual systems work for less critical measurements but require careful handling.

Production volume: Manual tools are suitable for small batches or occasional measurements. Semi-automatic systems handle large-scale production efficiently, saving time and effort.

Budget: Manual systems have a lower upfront cost, making them ideal for tight budgets. Semi-automatic tools cost more initially but can improve productivity and reduce long-term labor costs.

Operator skill: Skilled operators can take full advantage of manual tools. Semi-automatic systems help less experienced staff achieve reliable results with minimal training.

Integration: If your workflow includes digital data collection or automation, semi-automatic systems integrate smoothly. Manual tools may require extra steps for digital recording.

Manual vs Semi-Automatic: Side-by-Side Comparison

Have a glance here the measurement system comparison in the table below:

| Feature | Manual Systems | Semi-Automatic Systems |

| Speed | Slower | Faster |

| Accuracy | Operator-dependent | Consistent |

| Cost | Low | Higher |

| Ease of use | Simple | Requires training |

| Ideal application | Low-volume or precision tasks | High-volume or automated tasks |

Real-World Applications

Manual measuring systems are preferred in small workshops, labs with low-volume testing, or tasks requiring hands-on control.

Semi-automatic systems excel in manufacturing, quality control labs, or environments needing fast, repeatable measurements.

Both types use precision measuring tools, but the choice depends on your speed and accuracy requirements.

Wrapping Up

Manual vs Semi-Automatic Measuring Systems each have strengths. Manual tools provide control and affordability, while semi-automatic systems offer speed and consistent accuracy. Evaluate your workflow, production volume, and precision needs to decide on the best system for your operations. Using the right system ensures efficiency and reliability in every measurement.