Laser Scanning in Dimensional Inspection for Manufacturing

Quality drives success in modern manufacturing. Every part must meet exact size and shape standards. Even small errors can cause big losses. This is where Laser Scanning in Dimensional Inspection changes the game. It brings speed, accuracy, and automation to the inspection process. Unlike manual tools, laser-based systems capture precise data without touching the component. Manufacturers now rely on this technology to meet strict quality standards and boost production efficiency.

What is Laser Scanning in Dimensional Inspection?

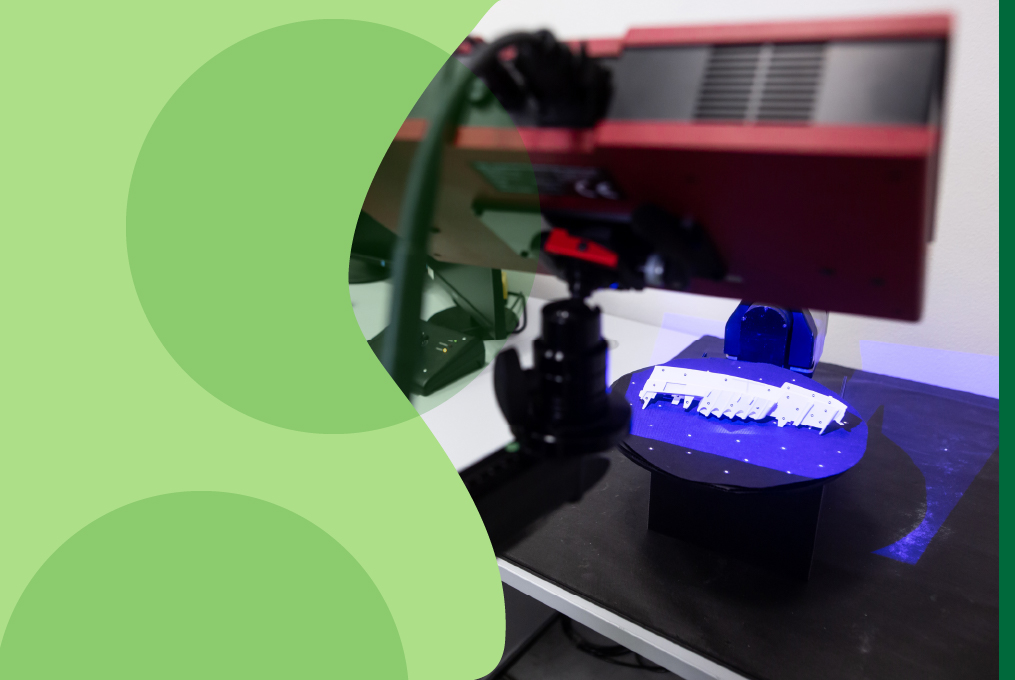

Laser Scanning in Dimensional Inspection uses laser beams to measure the physical dimensions of a part. The scanner moves around the object and collects millions of data points in seconds. These points form a detailed digital model. Engineers then compare this model with the original CAD design.

This method works without contact, which makes it safe for fragile and complex components. It supports flat parts, curved surfaces, and irregular shapes with equal precision.

Importance of Laser Scanning in Manufacturing

Manufacturing runs on accuracy. A single faulty batch can cause heavy financial loss. Laser Scanning in Dimensional Inspection ensures that every component matches design tolerance before it reaches the market.

It reduces inspection time from hours to minutes. It also lowers human error. Manufacturers gain consistent quality across large volumes. This technology also supports real-time feedback, which helps teams correct production issues early.

How 3D Laser Scanning Works for Inspection?

The process starts when the scanner projects a laser beam onto the part surface. Sensors capture the reflected light. Software converts this data into a point cloud. This cloud forms a precise 3D model.

With 3D Laser Scanning for Manufacturing, engineers compare the scanned data with CAD drawings. The system highlights deviations with color maps and numeric values. This makes it easy to spot defects and alignment issues instantly.

Key Benefits of Laser Scanning for Dimensional Inspection

Laser Scanning in Dimensional Inspection delivers unmatched advantages for manufacturers:

Non-contact measurement: The scanner does not touch the surface, which prevents scratches, dents, or distortion. This makes it safe for fragile, polished, and complex components.

High-speed data capture: It collects millions of measurement points within seconds. This creates a highly detailed 3D model and helps detect even the smallest dimensional variations.

Consistent inspection results: Laser scanning delivers the same level of accuracy every time. This ensures uniform quality across multiple production batches and inspection cycles.

Supports automation and digital workflows: The system integrates easily with CAD software, quality control platforms, and smart factory environments for faster, data-driven decisions.

Reduces scrap and rework costs: Early detection of errors prevents defective parts from advancing through production, saving material, labor, and operational costs.

Improves overall product quality: Accurate measurements lead to better fitting parts, fewer defects, and higher customer satisfaction.

Saves time and resources: Faster inspection cycles reduce downtime and improve overall manufacturing efficiency.

Applications of Laser Scanning in Manufacturing

Laser Scanning in Dimensional Inspection supports a wide range of industries. In automotive plants, it checks body panels, engine components, and fixtures. Aerospace companies use it for turbine blades and structural parts.

Heavy engineering firms rely on it for large castings and fabricated parts. Sheet metal and tooling industries also benefit from fast and accurate inspection. With 3D Laser Scanning for Manufacturing, even large assemblies get measured with ease and consistency.

Comparison with Traditional Dimensional Inspection Techniques

Traditional tools include calipers, micrometers, and coordinate measuring machines. These tools work well for simple parts. But they struggle with complex shapes and tight production timelines.

Modern Dimensional Inspection Techniques using laser systems deliver full surface coverage instead of limited point checks. They reduce manual effort and support digital analysis. Compared to older Dimensional Inspection Techniques, laser scanning offers faster results, better data depth, and improved repeatability.

Challenges and Limitations

Despite its benefits, this technology has limits. Highly reflective or transparent surfaces can affect scan quality. Dust and vibrations also impact accuracy. Initial setup costs stay high for small businesses. Data processing needs trained operators and powerful software.

Even with these challenges, the long-term return on investment remains strong for most manufacturers.

Future of Laser Scanning in Manufacturing Inspection

The future looks promising. AI-based defect detection continues to grow. Industry 4.0 integration improves smart factory workflows. Cloud-based data analysis enhances collaboration across locations. Portable scanners now allow on-site inspection without stopping production. These innovations push Laser Scanning in Dimensional Inspection toward wider adoption in every manufacturing sector.

Final Words

Manufacturers demand speed, accuracy, and reliability. Laser Scanning in Dimensional Inspection delivers all three. It transforms how companies measure, validate, and improve product quality. With rapid data capture, non-contact measurement, and digital integration, it now stands as a core tool for modern quality control. As technology evolves, laser-based inspection will only become more essential for competitive manufacturing.