Inside the Tool Room: How Precision Moulding Shapes Industrial Manufacturing

During this fast-paced industrial world, precision and efficiency are more important than ever. This blog explores how precision moulding shapes industrial manufacturing, ensuring components are accurate, reliable, and ready for large-scale production. It also highlights the crucial role of tool room processes in creating high-quality moulds and improving overall manufacturing performance. From reducing material waste to speeding production cycles, this blog shows why precision moulding is a cornerstone of modern industries.

What is Precision Moulding?

Precision moulding, also called exact mould fabrication, involves shaping materials into highly accurate components. It uses metals, plastics, and composites to produce parts with consistent dimensions. This process minimizes errors and maintains uniformity in mass production. High-quality moulds are vital for achieving tight tolerances and reliable performance.

The Role of the Tool Room in Manufacturing

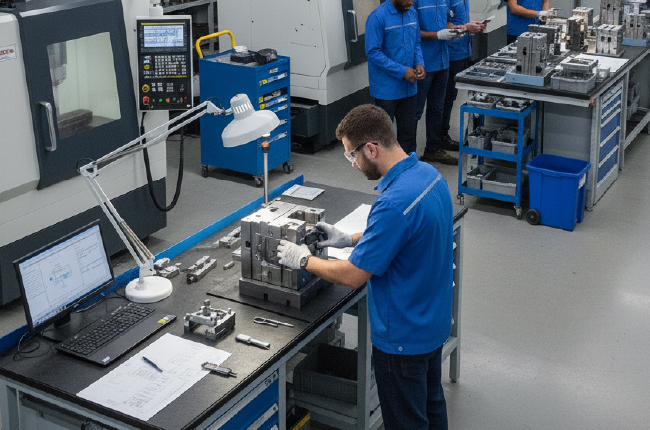

The tool room is often called the backbone of industrial manufacturing, and for good reason. It’s where raw ideas and designs are transformed into precise moulds that will guide the production of countless components. Skilled technicians in the tool room use advanced machinery, such as CNC machines, milling machines, and grinders, to cut, shape, and finish moulds with exacting accuracy.

Tool room processes go beyond just fabrication. They include thorough inspection and testing of each mould to ensure it meets tight tolerances and design specifications. Any error at this stage can lead to defective parts, production delays, or higher costs.

Additionally, the tool room is a hub of innovation. Engineers and technicians collaborate to optimize mould designs for efficiency, durability, and material usage. By combining experience with advanced equipment, the tool room ensures that every mould supports high-quality, reliable manufacturing. In essence, without precise tool room processes, industrial manufacturing would struggle to maintain consistency, quality, and efficiency.

Step-by-Step Precision Moulding Process

By following these steps, companies reduce waste, improve efficiency, and produce reliable products.

Designing the Mould: Engineers use CAD and CAM tools to design moulds with precision.

Fabrication: Skilled workers create the mould using advanced machining equipment.

Testing and Quality Checks: Each mould undergoes inspection to ensure accuracy.

Production: The mould is used to mass-produce components with high consistency.

Benefits of Precision Moulding in Industrial Manufacturing

Precision moulding is a game-changer for industries, offering efficiency and accuracy that traditional processes often struggle to achieve. Its advantages include:

Enhanced Product Quality: Every component produced meets tight tolerances, ensuring consistent performance and reliability.

Uniformity Across Batches: Parts are identical across production runs, reducing errors and quality issues.

Reduced Material Waste: The precise shaping process minimizes leftover material, lowering production costs.

Faster Turnaround Times: Efficient moulding allows quicker production cycles, helping industries meet tight deadlines.

Cost Efficiency: With less waste and faster production, overall manufacturing costs decrease.

Scalability: The process supports large-scale production without sacrificing accuracy.

Applications Across Industries

This process is widely used in automotive, aerospace, electronics, and medical device manufacturing. From engine parts to electronic casings and surgical tools, precision moulding guarantees components fit perfectly and perform reliably. Each sector benefits from the combination of speed, accuracy, and consistency that precise moulds provide.

Challenges and Innovations

While precision moulding delivers great results, it comes with challenges. Material limitations and wear can affect mould life. However, innovations like 3D printing for mould creation and advanced surface coatings are helping manufacturers overcome these issues. Continuous improvements in tool room processes ensure higher efficiency and quality.

Final Thoughts

Precision moulding is more than just shaping materials—it drives industrial manufacturing forward. By combining skilled tool room processes with advanced technology, companies can produce high-quality components efficiently. As industries evolve, precision moulding will remain a cornerstone of modern manufacturing.