Innovative Applications of Laser Cutting in Sheet Metal Fabrication

Laser cutting has revolutionized many industries, and one of the key areas where it has made a significant impact is in sheet metal fabrication. This advanced technology offers precision, efficiency, and versatility, making it a preferred choice for many manufacturers. In this blog, we will explore some innovative applications of laser cutting in sheet metal fabrication and how it is transforming the industry.

Precision Cutting

One of the most notable advantages of laser cutting in sheet metal fabrication is its ability to achieve high precision. Traditional cutting methods often struggle with intricate designs and tight tolerances.

Laser cutting, however, can handle complex shapes and fine details with ease. This precision is crucial for industries like aerospace, automotive, and electronics, where even a small error can lead to significant problems.

Rapid Prototyping

Rapid prototyping is essential for product development. Laser cutting allows manufacturers to quickly create prototypes from sheet metal, enabling faster testing and refinement of designs. This speed is beneficial in reducing the time to market for new products.

Engineers can adjust and see the results almost immediately, which is not always possible with other cutting methods.

Customization and Flexibility

Laser cutting provides unmatched flexibility when it comes to customization. Whether it’s a single custom piece or a batch of parts, laser cutting can easily adapt to different requirements. This flexibility is particularly useful for industries that require bespoke solutions, such as medical device manufacturing and custom automotive parts.

Material Efficiency

Another innovative application of laser cutting in sheet metal fabrication is material efficiency. Laser cutting minimizes waste by making precise cuts and optimizing the use of raw materials. This efficiency is both cost-effective and environmentally friendly.

Manufacturers can reduce material costs and decrease their carbon footprint, which is becoming increasingly important in today’s world.

Complex Geometries

Traditional cutting methods often struggle with complex geometries and intricate patterns. Laser cutting, on the other hand, excels in this area. It can cut complex shapes and detailed patterns that would be difficult or impossible with other methods.

This capability is particularly beneficial for industries such as architecture and interior design, where aesthetic appeal is important.

High-Speed Production

Speed is a critical factor in manufacturing, and laser cutting offers high-speed production capabilities. The laser moves quickly and accurately, reducing the time needed to produce each part. This speed is advantageous for large-scale production runs, helping companies meet tight deadlines and increase their overall productivity.

Improved Edge Quality

Laser cutting produces clean, smooth edges on sheet metal parts. This improved edge quality reduces the need for additional finishing processes, such as grinding or polishing. The result is a higher-quality product with less time and effort spent on finishing.

This is particularly important for industries like consumer electronics, where the final appearance of the product is crucial.

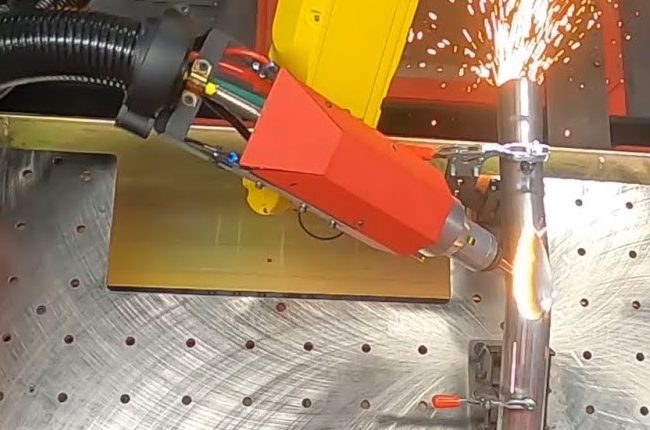

Automation and Integration

Modern laser cutting systems can be easily integrated with automation technologies, such as robotic arms and conveyor systems. This integration enhances production efficiency and reduces labor costs. Automated laser cutting systems can operate continuously, increasing throughput and consistency. This automation is especially useful in high-volume manufacturing environments.

Conclusion

The innovative applications of laser cutting in sheet metal fabrication are transforming the industry. With its precision, speed, flexibility, and efficiency, laser cutting is becoming an indispensable tool for manufacturers across various sectors.

From rapid prototyping to complex geometries and improved edge quality, the advantages of laser cutting are clear. As technology continues to advance, we can expect even more exciting developments in the field of laser cutting, further enhancing its impact on sheet metal fabrication.

Laser cutting has not only improved the way we manufacture products but also opened new possibilities for design and customization. It is a technology that continues to push the boundaries of what is possible in sheet metal fabrication, making it an essential part of modern manufacturing.