Innovations in Sheet Metal Punching: Speed & Precision

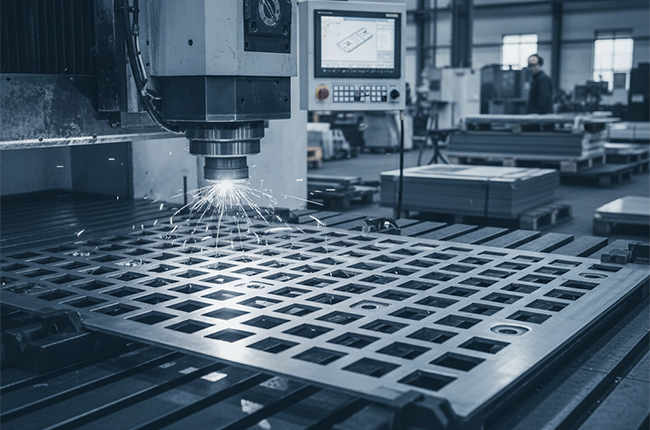

Sheet metal punching has become one of the most essential processes in modern manufacturing. Whether it’s automotive components, aerospace parts, or industrial machinery, accurate and fast punching plays a key role in achieving high-quality results. Today, innovations in sheet metal punching are transforming the way industries create metal components. New technologies now allow for greater punching speed, precision, and design flexibility, helping manufacturers produce parts faster and with minimal waste. Let’s explore how these innovations are shaping the future of sheet metal punching and why adopting them can make a big difference to your production efficiency and product quality.

The Evolution of Sheet Metal Punching Technology

Traditionally, sheet metal punching is a manual or semi-automated process that requires constant operator supervision. Accuracy depended on human skill, and even small errors could lead to material wastage or inconsistent results.

However, with the introduction of CNC punching machines and advanced automation systems, things have changed completely. These modern machines can handle complex patterns, multiple hole sizes, and high-speed operations with incredible accuracy.

Today’s CNC punching systems use computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to guide every punch with perfection. This level of precision ensures that every sheet metal part meets the exact design specifications — no matter how complex the geometry is.

Key Innovations Driving Speed and Precision

1. CNC Automation for Faster Operations

Automation has been one of the biggest game-changers in the sheet metal punching industry. With CNC automation, manufacturers can now process large batches of metal sheets in less time, reducing manual intervention and increasing productivity.

These automated machines can perform multiple punching actions in one setup, allowing for faster cycle times and consistent results. Plus, they reduce the chances of human error — ensuring greater accuracy and repeatability.

2. CAD-CAM Integration for Error-Free Design

CAD-CAM integration has made it easier to convert design ideas into real products. Engineers can design complex layouts digitally and send them directly to the punching machine for production.

This digital-to-machine flow eliminates design errors and ensures each hole, slot, or pattern is punched at the correct position and depth. This not only improves punching precision but also saves time in programming and setup.

3. Advanced Tooling for Complex Designs

Modern sheet metal punching machines now come with advanced tooling systems that allow for quick tool changes and multi-tool setups. These tools can handle different shapes and thicknesses with minimal downtime.

High-quality punching tools also last longer and maintain sharpness even under heavy production loads. This helps maintain consistent punching quality across all batches, especially when producing components for industries like aerospace, electronics, and automotive.

4. Servo-Electric Technology for Energy Efficiency

Another major innovation is the use of servo-electric punching machines. Unlike hydraulic systems, servo-driven machines use electric motors for precise control of punching speed and force.

This technology not only improves accuracy but also reduces energy consumption and maintenance needs. Manufacturers get eco-friendly, high-speed punching while keeping operational costs under control.

5. Real-Time Monitoring and Smart Controls

Smart manufacturing has entered the sheet metal industry through IoT-enabled punching machines. These systems can track real-time data such as punching speed, tool wear, and material usage.

This data helps operators make instant adjustments, improve process efficiency, and prevent downtime. With these insights, companies can plan better and maintain consistent sheet metal punching precision across all projects.

Benefits of Modern Sheet Metal Punching

Adopting innovative sheet metal punching technologies brings several advantages to manufacturers:

Higher production speed: Automated machines and optimized tooling drastically reduce punching time.

Greater accuracy: CAD-CAM systems and servo control ensure every punch is exactly where it should be.

Reduced waste: Precise punching means less material is wasted, helping save costs.

Flexibility in design: Advanced tooling supports multiple patterns and materials.

Consistency and repeatability: Once programmed, machines can deliver identical results for large production runs.

Improved energy efficiency: Servo-electric machines consume less power and produce less noise.

These benefits make modern sheet metal punching systems a valuable investment for companies that want to stay competitive in global manufacturing markets.

Applications Across Industries

Innovative sheet metal punching technology serves many industries across the globe, such as:

Aerospace: For creating lightweight yet durable metal parts.

Automotive: For high-precision components like brackets and panels.

Electronics: For finely punched enclosures and connectors.

Construction: For perforated panels, ventilation systems, and support.

Renewable Energy: For parts used in solar panel mounts and wind turbine components.

No matter the industry, speed and precision in sheet metal punching help improve performance, durability, and cost-efficiency of the final product.

Why Partner with VmakeU for Advanced Sheet Metal Punching

At VmakeU, we bring together cutting-edge technology, skilled professionals, and a commitment to quality to deliver top-notch sheet metal punching services.

Our advanced CNC punching machines, CAD-CAM integration, and smart automation systems ensure your projects are completed with maximum precision and efficiency. Whether you need complex perforations, custom designs, or large-volume production, we have the tools and expertise to make it happen.

If you’re looking for innovative sheet metal punching solutions that combine speed, accuracy, and reliability — VmakeU is your trusted manufacturing partner.