Importance of Dimensional Inspection in High-Precision Manufacturing

When it comes to high-precision manufacturing, every millimeter matters. Even a small deviation in size or shape can affect how a part fits, functions, or performs in the final assembly. This is where dimensional inspection plays a key role. It ensures that every component meets the exact specifications set during design and production. In today’s global manufacturing world, accuracy, consistency, and quality control depend heavily on this process. Let’s explore why dimensional inspection is so important and how it adds value to high-precision manufacturing.

What is a Dimensional Inspection?

Dimensional inspection is the process of measuring the physical dimensions of a part or component to ensure it matches the required specifications. These measurements can include length, width, height, thickness, diameter, angles, and surface features.

In high-precision industries such as aerospace, automotive, defense, and medical manufacturing, even a tiny error can cause major issues. Dimensional inspection helps detect these errors early and ensures that only accurate parts move forward in the production process.

Why Dimensional Inspection is Important in High-Precision Manufacturing

1. Ensures Accuracy and Consistency

Accuracy is the foundation of precision manufacturing. Dimensional inspection makes sure that every component is produced to exact measurements. Whether it’s a single prototype or a bulk production run, inspection tools such as Coordinate Measuring Machines (CMMs) and laser scanners ensure all parts stay within the required tolerances.

By maintaining consistency across batches, manufacturers can avoid costly rework, material waste, and production delays. Consistency also builds trust with customers who depend on reliable and high-performing parts.

2. Improves Product Quality

Quality is not just about how a product looks—it’s about how well it performs. Dimensional inspection guarantees that all parts meet the intended design and functional requirements. When each component is inspected thoroughly, manufacturers can identify defects before they reach the customer.

High-quality inspection systems catch even the smallest deviations, reducing the risk of assembly failures or product recalls. This not only improves performance but also enhances brand reputation in competitive global markets.

3. Reduces Manufacturing Costs

It might seem that inspection adds extra steps to production, but in reality, it helps save money in the long run. By catching issues early, dimensional inspection prevents expensive rework, scrap, or production downtime.

A precise inspection process also helps manufacturers optimize machine calibration and improve process stability. Over time, this leads to higher efficiency, fewer rejections, and better utilization of raw materials.

4. Supports Innovation and Complex Designs

Modern industries are moving toward complex, custom-designed parts with tight tolerances. Dimensional inspection makes it possible to verify these advanced geometries with great accuracy.

For instance, in aerospace and automotive manufacturing, 3D scanning and advanced metrology systems ensure that even the most intricate parts meet exact design standards. This capability allows companies to innovate confidently, knowing their production process can handle complex requirements.

5. Maintains Compliance with Industry Standards

High-precision manufacturing often requires compliance with strict international standards such as ISO 9001, AS9100, or IATF 16949. Dimensional inspection is a major part of these standards, as it ensures traceability, documentation, and quality assurance at every stage.

With proper inspection data, manufacturers can prove compliance during audits, demonstrate accountability to clients, and maintain certifications that open doors to global business opportunities.

6. Strengthens Customer Confidence

Customers in industries like aerospace, automotive, and energy depend on precision and reliability. Dimensional inspection helps manufacturers deliver on those expectations.

When clients know that every part is thoroughly inspected and meets international standards, it builds trust. This trust leads to stronger partnerships, repeat business, and a solid reputation in global markets.

Common Dimensional Inspection Techniques

High-precision manufacturing uses several methods to measure and verify parts. Some common techniques include:

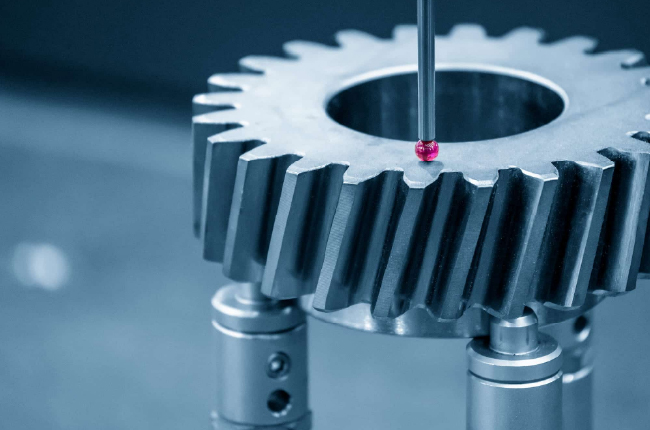

Coordinate Measuring Machines (CMMs): Used to measure complex parts with high accuracy.

Laser Scanning: Captures precise 3D images of components for analysis and reverse engineering.

Optical Measurement Systems: Non-contact inspection ideal for delicate or soft materials.

Surface Profilers: Used to measure roughness, flatness, and texture.

Each of these methods plays a unique role in ensuring that manufactured parts meet design and quality requirements.

The Role of Technology in Dimensional Inspection

As manufacturing moves toward automation and smart production, dimensional inspection has also evolved. Advanced sensors, computer vision, and AI-based systems now make it possible to perform real-time inspection during production.

These systems can quickly identify errors and provide instant feedback to operators, reducing downtime, and improving overall quality control. This integration of technology is transforming how manufacturers achieve precision and efficiency.

Choosing the Right Partner for Precision Manufacturing

For companies that require accuracy, reliability, and speed, choosing the right manufacturing partner is essential. A partner with advanced inspection systems and quality control processes can make a huge difference in product performance and customer satisfaction.

At VmakeU, we understand how crucial precision is in modern manufacturing. Our advanced dimensional inspection systems ensure that every part meets exact specifications before it reaches our clients. From aerospace components to industrial machinery, our team follows global standards to deliver high-quality, reliable results every time.

Conclusion

Dimensional inspection is not just a step in the manufacturing process—it is the backbone of high-precision manufacturing. It ensures that every product meets design expectations, performs perfectly, and builds trust among customers.

For manufacturers aiming for excellence and long-term success, investing in accurate and reliable dimensional inspection is essential. It improves efficiency, reduces costs, and supports innovation in an increasingly competitive world.