How VmakeU Uses 3D Design and Prototyping to Enhance Manufacturing Efficiency

Manufacturing is all about precision, speed, and quality. At VmakeU, we know this better than anyone. One of the ways we ensure that we stay ahead in the game is by using advanced 3D design and prototyping. This method has completely changed how we approach manufacturing, making the process smoother, faster, and more efficient. But what exactly is 3D design and prototyping? And how does it help us improve our manufacturing? Let’s break it down in simple terms.

What is 3D Design?

3D design is the process of creating a digital model of a product or part on a computer. Unlike a 2D sketch, a 3D model lets you see every angle and detail of the design, making it easier to understand how the final product will look and work. Think of it like drawing something in real life but on your computer—except this drawing isn’t flat. It’s a full, three-dimensional image that you can spin around, zoom in, and change as needed.

For VmakeU, this means we can design everything from small machine parts to large aerospace components in a way that’s incredibly detailed and precise.

What is Prototyping?

Once we have a 3D model, the next step is prototyping. A prototype is a sample version of the product that we build to test its design before mass production. This helps us catch any design flaws or issues early on, ensuring the final product is perfect.

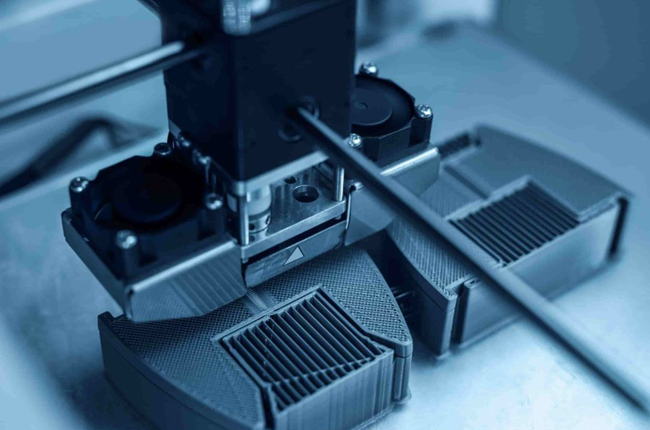

3D prototyping, also known as rapid prototyping, allows us to create physical models of our 3D designs quickly. This is usually done through 3D printing or other advanced methods that turn the digital model into a real object.

Now that we’ve got the basics down, let’s dive into how using 3D design and prototyping at VmakeU enhances our manufacturing efficiency.

Faster Design Process

Traditionally, designing a product would take weeks or even months. Engineers would first sketch their ideas on paper, build a physical prototype, and then make changes based on how the prototype worked. If something was wrong, they would have to go back to the drawing board, make changes, and repeat the process. This was time-consuming and expensive.

With 3D design, we can create, edit, and test a product design digitally before building anything physical. This significantly reduces the time spent on the design phase. Instead of manually making a new prototype each time a change is needed, we just update the digital model. Changes that used to take days or weeks can now be made in hours or even minutes!

This faster design process allows us to move quickly from idea to production. It also means we can handle more projects in less time, increasing our overall efficiency.

Better Communication and Collaboration

Another advantage of 3D design is that it improves communication between our team members and clients. With a 3D model, everyone can easily see the product from all angles, making it easier to understand how it works. This is especially helpful when working with clients in industries like aerospace or automotive, where parts are often very complex.

Because the model is digital, we can share it instantly with clients for feedback, even if they are on the other side of the world. This leads to faster approvals and fewer misunderstandings, speeding up the overall production process.

Reducing Errors with Prototyping

When it comes to manufacturing, even small errors in the design can lead to big problems during production. Prototyping helps us catch these issues early. By building a physical prototype from the 3D model, we can see how the design will actually work in real life. If there’s a problem—like a part not fitting correctly or a material not being strong enough—we can spot it early and make changes before moving to full-scale production.

At VmakeU, our use of 3D prototyping has drastically reduced the number of errors we encounter during the production process. This means less wasted time and materials, leading to greater efficiency and cost savings.

Customization and Flexibility

3D design and prototyping also give us greater flexibility when it comes to customization. Many of our clients have specific needs and may require custom designs for their projects. With traditional methods, creating a custom product would take a lot of time and resources. But with 3D design, we can easily adjust a digital model to fit the client’s specifications and create a prototype for approval.

This makes it easier for us to deliver exactly what the client needs, without delaying the production process.

Sustainable Manufacturing

At VmakeU, we are committed to sustainable manufacturing. By using 3D design and prototyping, we can minimize waste during production. Since we can test and perfect the design digitally, we don’t need to create multiple physical prototypes, which often end up being discarded. This reduces our use of raw materials and energy, making our production process more eco-friendly.

Conclusion

3D design, and prototyping have transformed the way VmakeU approaches manufacturing. From speeding up the design process to reducing errors and increasing customization, these technologies have made our operations more efficient and reliable. Not only does this benefit us, but it also ensures that our clients get high-quality products quickly and at a lower cost.

By using these modern tools, we’re not just improving our manufacturing process—we’re also shaping the future of the industry.