How to Implement Design for Reliability in Your Projects

Imagine launching a product that customers love—not only for its features, but because it works smoothly and reliably every time. That doesn’t happen by luck. It happens when reliability is built into the design from the very beginning. Design for Reliability means making reliability a priority, building trust with every choice, and ensuring your project performs well today and in the future. Suppose you’re tired of firefighting after launch, warranty claims, or disappointed users. Read on. In that case, this guide will show you how to embed reliability into your projects so that failure becomes the exception, not the rule.

What is Design for Reliability (DfR)?

Design for Reliability is a disciplined engineering mindset and methodology that ensures a system, product, or component reliably performs its intended function over its expected lifetime, under specified conditions. It’s not about testing after you build—it’s about planning and predicting failures from day one, then designing them out. According to Ansys, it involves integrating product design with process planning, using tools to anticipate potential issues early.

Why Reliability Matters in Projects

Reliability isn’t just a technical factor—it directly impacts cost, customer trust, and compliance. These are the key reasons why it matters in every project:

Cost savings – Fixing reliability issues late in development or after launch is exponentially more expensive than preventing them during design.

Customer satisfaction & reputation – Reliable products build loyalty and trust. When failures are rare, reliability itself becomes a strong selling point.

Regulatory & usage reliability – In industries like automotive, aerospace, medical devices, and electronics, strict reliability standards related to lifecycle, safety, and uptime are non-negotiable.

Core Principles of Design for Reliability

To build truly dependable systems, certain guiding principles must shape the design process from the beginning. Here are the foundations of a strong reliability strategy:

Define clear reliability goals early – Set measurable targets like MTBF, uptime, or failure rate while considering really environmental and usage conditions. This creates a solid benchmark for design decisions.

Understand failure mechanisms – Study the Physics of Failure to identify root causes, so your design eliminates problems at their source instead of patching symptoms later.

Redundancy and robust design – Incorporate backups, fail-safes, and tolerance to variations so the system performs even under unexpected stresses.

Early reliability testing, simulation & modelling – Apply tools like FMEA, Fault Tree Analysis, and stress testing during design to reveal weak points before launch.

Continuous improvement based on feedback – Use field data, failure reports, and performance metrics to refine designs, ensuring each iteration is more reliable than the last.

Steps to Implement Design for Reliability in Your Projects

These are the essential steps you can follow to successfully embed reliability into your project lifecycle:

Step 1: Define reliability goals and requirements

Set measurable targets such as MTBF, failure rates, or uptime expectations. Include environmental factors like temperature, vibration, and humidity to make goals realistic.

Step 2: Integrate reliability early in design

Factor reliability into material selection, architecture, and component choices. Design modular systems to isolate failures and simplify maintenance.

Step 3: Apply Reliability Engineering Best Practices

Use methods like FMEA and Fault Tree Analysis to identify weak points. Model system reliability with block diagrams and predictive analysis.

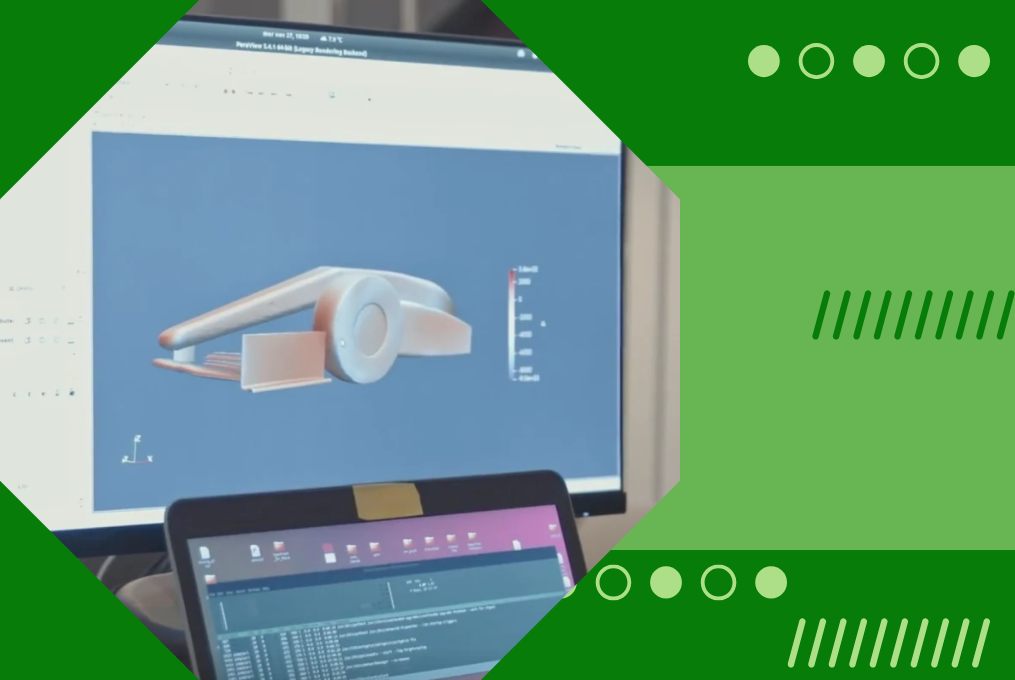

Step 4: Run simulations and accelerated testing

Use digital simulations to test against mechanical, thermal, and electrical stresses. Conduct HALT and life-cycle testing to uncover early failure modes.

Step 5: Validate through prototypes and verification

Build and test prototypes under real-world and extreme stress conditions. Confirm the design meets reliability requirements before scaling production.

Step 6: Monitor and improve continuously

Collect performance and failure data after launch to measure real reliability. Feed insights back into design updates for stronger next-generation products.

Tools & Techniques

These are the key tools that help engineers anticipate failures, strengthen designs, and ensure systems perform reliably throughout their lifecycle:

Failure Mode and Effects Analysis (FMEA)

Fault Tree Analysis (FTA)

Reliability Block Diagrams (RBD)

Accelerated Life Testing / Highly Accelerated Life Tests (HALT)

Physics of Failure (PoF) Modelling

Challenges in Implementing Design for Reliability

These are the common hurdles organizations face when trying to integrate reliability into their projects:

Cost and time trade-offs – Greater robustness often adds expense or extends development cycles, while decision makers may prioritize speed to market.

Uncertainty in usage/environment – Real-world conditions can be difficult to predict, leading to unexpected stresses on the product.

Organizational culture & skills – Teams may lack the expertise or mindset for reliability, and stakeholders sometimes undervalue investing in it early.

Best Practices for Success

To make Design for Reliability stick:

Involve cross-functional teams (design, quality, production, maintenance) from the start.

Use Reliability Engineering Best Practices such as data-driven decisions, leveraging field data and analytics.

Prioritize reliability requirements in all specifications, supplier contracts, and component selections.

Make it iterative: redesign, test, field feedback; loop back to design.

Final Words

If you want products that customers don’t just buy, but trust, then Design for Reliability has to be part of your DNA. It’s not an optional extra—it’s the foundation for long-term performance, savings, and reputation. Use the Reliability by Design Process, apply Reliability Engineering Best Practices, and commit to building feedback loops. Do this, and reliability becomes your competitive advantage, not your afterthought.