How Sheet Metal Fabrication Revolutionized the Manufacturing Industry

In the world of manufacturing, sheet metal fabrication stands tall as a true game-changer. This process has transformed the way we make things, leading to efficiency, versatility, and affordability. Let’s investigate how sheet metal fabrication has revolutionized the manufacturing industry.

Sheet Metal Fabrication

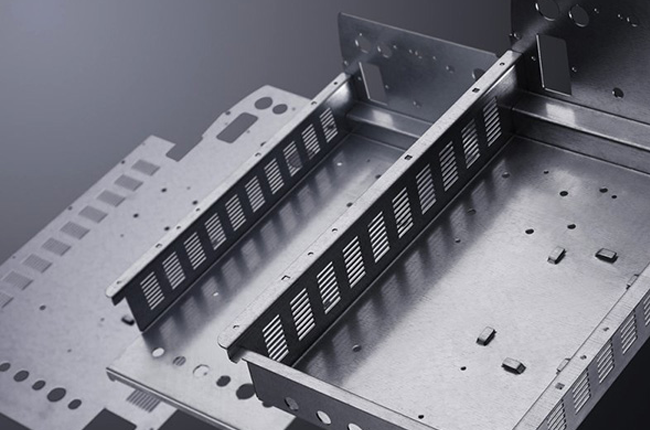

Sheet metal fabrication is a process of forming, shaping, and assembling metal sheets into various products. These sheets, often made of steel, aluminium, or other metals, are transformed into parts and components used in industries ranging from automotive to aerospace.

Efficiency in Production

One of the key benefits of sheet metal fabrication is its efficiency in production. Unlike traditional methods that involve cutting and shaping metals manually, sheet metal fabrication uses advanced techniques like CNC laser cutting, CNC punching, and CNC bending machines. These technologies allow for precise and rapid production of parts, reducing manufacturing time and costs.

Versatility in Design

Another remarkable aspect of sheet metal fabrication is its versatility in design. With modern CAD (Computer-Aided Design) software, engineers can create complex designs with ease. These designs can then be translated into precise instructions for fabrication machines, ensuring accuracy and consistency in the final product.

Whether it's simple brackets or intricate enclosures, sheet metal fabrication can handle a wide range of designs.

Cost-Effectiveness

Sheet metal fabrication offers cost-effectiveness in several ways. Firstly, the efficiency in production leads to lower labor costs as fewer workers are needed for manufacturing. Secondly, the ability to recycle scrap metal reduces material costs.

Additionally, the versatility in design allows for optimization of material usage, minimizing waste and further reducing costs.

Strength and Durability

Products made through sheet metal fabrication are known for their strength and durability. Sheet metal parts can withstand high temperatures, pressure, and environmental factors, making them suitable for various applications. Whether it's a car chassis or an industrial machine enclosure, sheet metal components provide robustness and reliability.

Adaptability to Customization

In today's manufacturing landscape, customization is increasingly important. Sheet metal fabrication excels in this aspect by offering adaptability to customization. Whether it's a prototype or a mass-produced item, sheet metal fabrication can accommodate customization requirements easily.

This flexibility allows manufacturers to meet the diverse needs of their customers efficiently.

Environmental Sustainability

Sheet metal fabrication promotes environmental sustainability through several means. Firstly, the recyclability of metals reduces the demand for virgin materials, conserving natural resources. Secondly, the efficiency in production reduces energy consumption, lowering the carbon footprint of manufacturing processes. Additionally, the ability to optimize material usage minimizes waste generation, further contributing to a greener environment.

Application Across Industries

The impact of sheet metal fabrication is felt across various industries. In automotive manufacturing, it's used for making car bodies, chassis, and engine components. In aerospace, it's employed for producing aircraft parts like wings and fuselage.

In electronics, it's used for making enclosures and heat sinks. The list goes on, demonstrating the widespread adoption of sheet metal fabrication in modern manufacturing.

Final Thoughts

In conclusion, sheet metal fabrication has truly revolutionized the manufacturing industry. With its efficiency, versatility, cost-effectiveness, strength, and adaptability, it has become a cornerstone of modern manufacturing processes.

From automotive to aerospace, from electronics to construction, sheet metal fabrication continues to shape the world we live in, driving innovation and progress.