How Advanced Welding Ensures Structural Integrity

When it comes to metal fabrication, structural integrity is everything. Whether it’s an aircraft component, an automotive frame, or a bridge support, the strength and safety of any metal structure depend heavily on the quality of its welding. That’s where advanced welding techniques play a vital role. These modern methods are not just about joining metals—they are about ensuring reliability, durability, and precision in every joint. Let’s take a closer look at how advanced welding ensures strong, long-lasting, and flawless structures across industries.

Understanding the Importance of Structural Integrity

Structural integrity means that a structure can bear the loads and stresses it is designed for, without breaking or deforming. In industries like aerospace, automotive, energy, and construction, even a small welding defect can lead to serious issues—ranging from mechanical failure to safety hazards.

This is why manufacturers now depend on advanced welding technologies to ensure uniform strength, accurate results, and high-quality finishes. These modern welding techniques combine precision engineering, automation, and material science to deliver joints that are not only strong but also consistent and clean.

The Role of Advanced Welding in Modern Manufacturing

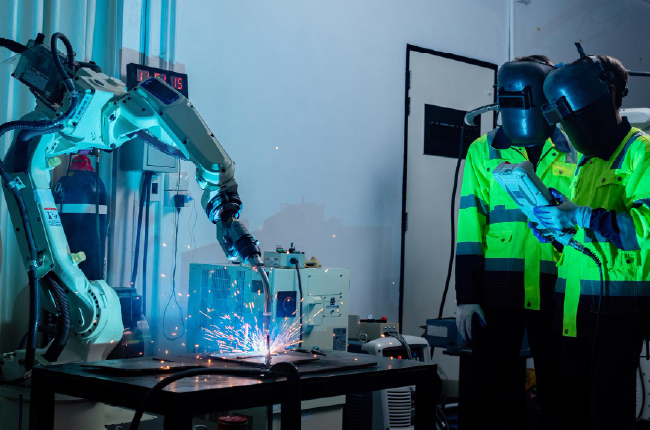

Advanced welding has transformed how products are built today. Traditional methods like manual arc welding, while effective, often depend on the welder’s skill and experience. However, advanced processes like laser welding, TIG welding, and MIG welding use automation, robotics, and computer control to enhance accuracy and reduce human error.

These advanced welding processes ensure:

High precision and repeatability

Deeper weld penetration for stronger joints

Minimal distortion or deformation

Clean, aesthetic weld finishes

Consistent results even in mass production

For manufacturers who serve industries where quality and safety cannot be compromised, these advantages make a big difference.

How Advanced Welding Enhances Structural Strength

The strength of a welded structure depends on several factors—heat control, material compatibility, and weld consistency. Advanced welding systems manage all of these efficiently.

For example:

Laser welding delivers concentrated heat, allowing deep and narrow welds that hold better under stress.

TIG welding offers clean, precise welds that are ideal for thin materials or complex assemblies.

MIG welding ensures speed and uniformity in thicker materials.

By using automation and advanced monitoring systems, manufacturers can achieve perfect control over every weld. This level of accuracy directly contributes to structural reliability and performance, especially in high-stress applications like aircraft, vehicles, and machinery.

Precision Welding for Safety and Durability

In industries like aerospace and automotive manufacturing, safety standards are extremely high. Any minor welding flaw can weaken a component and put lives at risk. That’s why precision welding is now a top priority in these sectors.

Modern welding systems use real-time data monitoring, robotic assistance, and advanced sensors to detect irregularities during the process. This ensures that each weld meets the exact strength and alignment required by design specifications.

Durability is another major advantage. Advanced welding prevents microcracks, porosity, or uneven bonding—issues that could otherwise lead to premature wear or failure. The result is a structure that performs reliably under heavy loads, vibrations, and environmental stress.

Aesthetic Finishes with Advanced Welding

While structural strength is the main goal, appearance also matters—especially in industries like automotive design, consumer electronics, and architectural fabrication. Advanced welding techniques produce smooth, clean, and visually appealing finishes without the need for extensive post-weld grinding or polishing.

For instance, laser welding creates nearly invisible seams, making it ideal for parts that demand both strength and aesthetic precision. This not only saves time but also enhances the final product’s look and value.

Reducing Waste and Increasing Efficiency

Another major benefit of advanced welding technology is improved efficiency. Automated welding systems use exact amounts of heat and filler materials, which reduces material waste and energy consumption.

Moreover, these systems operate faster and more consistently than manual welding, allowing manufacturers to meet tight deadlines without compromising quality. For global companies, this means improved productivity, lower costs, and faster delivery—all while maintaining top-tier structural integrity.

Applications of Advanced Welding Across Industries

Advanced welding is now an essential part of industries such as:

Aerospace: for lightweight yet durable aircraft components.

Automotive: for strong chassis and precision joints.

Energy: pipelines, pressure vessels, and renewable energy equipment.

Construction: for metal frameworks and infrastructure projects.

Electronics: compact, high-precision assembly.

Each of these industries relies on accurate and defect-free welds to ensure that their products perform safely and effectively over time.

The Future of Welding: Automation and Intelligence

The future of welding technology lies in automation and smart manufacturing. Advanced robotic systems and AI-driven weld monitoring are now being integrated into production lines, ensuring unmatched precision and consistency.

These innovations are making welding safer, faster, and more reliable than ever before. For global manufacturers, this means better structural quality, reduced downtime, and enhanced product value—all achieved through intelligent welding solutions.

Choose VmakeU for Precision and Quality

At VmakeU, we specialize in delivering high-quality metal fabrication and advanced welding solutions for industries around the world. Our team combines technical expertise with modern machinery to ensure every weld meets the highest standards of strength, precision, and aesthetics.

If your business needs reliable welding services that guarantee structural integrity, contact VmakeU today. Let’s build strong, efficient, and lasting structures together.