From Concept to Component: The Journey of a Mould in Modern Manufacturing

Precision mould manufacturing is the backbone of modern industrial production. It transforms innovative ideas into high-quality components used across automotive, aerospace, electronics, and other industries. The journey of a mould—from concept to final component—requires careful industrial mould design, skilled tool room processes, and exacting fabrication techniques. Every step ensures that the final product is reliable, durable, and perfectly aligned with design specifications. This blog explores the full journey of a mould in modern manufacturing, highlighting the critical stages that make precision mould manufacturing a cornerstone of engineering excellence.

Importance of initial design and planning

Every successful mould starts as a concept. Engineers and designers sketch ideas and use CAD software to create detailed blueprints. Industrial mould design focuses on functionality, durability, and manufacturability. By simulating the mould in virtual environments, designers can identify potential issues before production begins. This step saves time and ensures the mould performs flawlessly when in use.

What is a tool room and its function in manufacturing?

The tool room is the heart of precision mould manufacturing. Skilled technicians follow specialized tool room processes such as cutting, shaping, and polishing to craft the mould. Every detail matters, from angles and curves to surface finishes. Precision is key—any small error can affect the final component’s quality. The tool room also handles testing, making adjustments, and ensuring the mould aligns with the original industrial mould design.

Mould Fabrication: Turning Design into Reality

Once the design is finalized, the next step is fabrication. This is where the concept becomes a physical mould ready for production. Here are the key aspects of this stage:

Material Selection and Preparation

Choosing the right material is critical. Steel and aluminum are common due to their durability and machinability. The material must withstand repeated production cycles without warping or wearing out. Once selected, it is cleaned, cut, and prepared for precise machining.

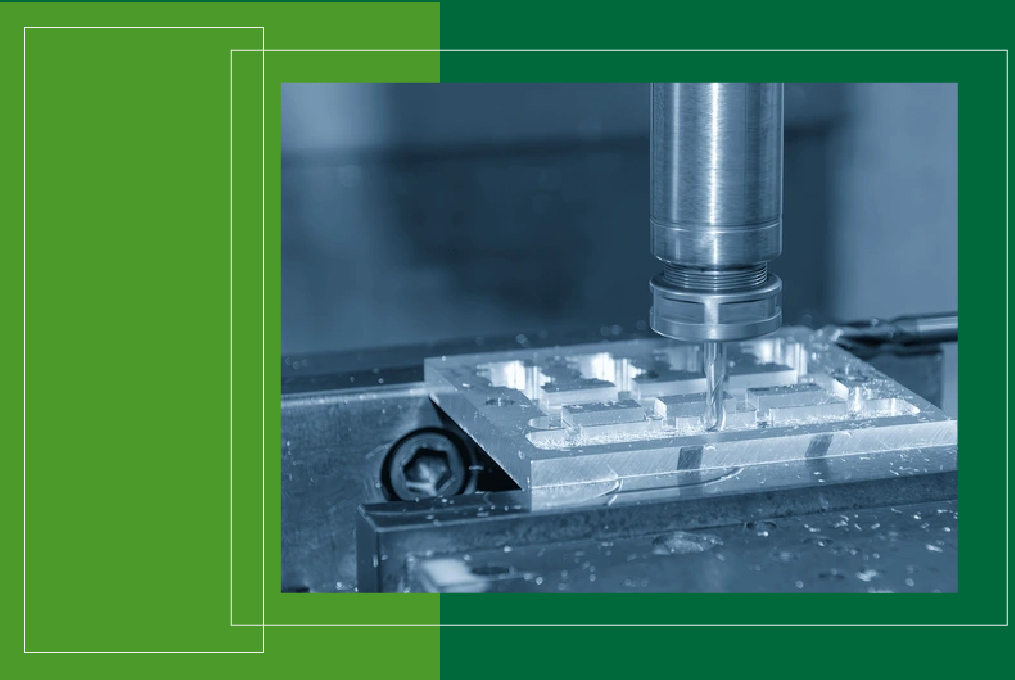

Machining and Assembly Techniques

Advanced machinery like CNC mills and EDM machines shape the mould according to the design. Technicians assemble multiple parts, ensuring perfect alignment. Every cut and joint is carefully measured to maintain dimensional accuracy. Precision at this stage determines the quality of components produced.

Challenges Faced During Fabrication

Fabrication is not without challenges. Materials can behave unexpectedly under stress or heat. Tiny errors in machining or assembly can lead to defects in the final product. Skilled technicians continuously monitor and adjust processes to overcome these issues, ensuring the mould meets exact specifications.

Testing and Validation

Before full-scale production, the mould must be thoroughly tested. Here are the key steps:

Trial Runs and Prototyping

Initial prototypes are produced to check how the mould performs under real conditions.

Ensuring Dimensional Accuracy and Surface Finish

Components are measured carefully to confirm they meet design specifications and have smooth finishes.

Adjusting Before Mass Production

Any minor defects or misalignments are corrected to ensure consistent quality in large-scale production.

Production and Component Manufacturing

After validation, the mould enters production. It creates components used in automotive, aerospace, electronics, and many other industries. High-quality moulds reduce waste, improve efficiency, and deliver consistent results. Precision mould manufacturing continues even during production, as regular inspections keep the mould in optimal condition.

Final Words

From concept to component, the journey of a mould highlights the importance of skill, accuracy, and advanced processes. Precision mould manufacturing combines careful design, expert tool room processes, and reliable industrial mould design to produce components that meet the highest standards. Each mould tells the story of craftsmanship and engineering excellence.