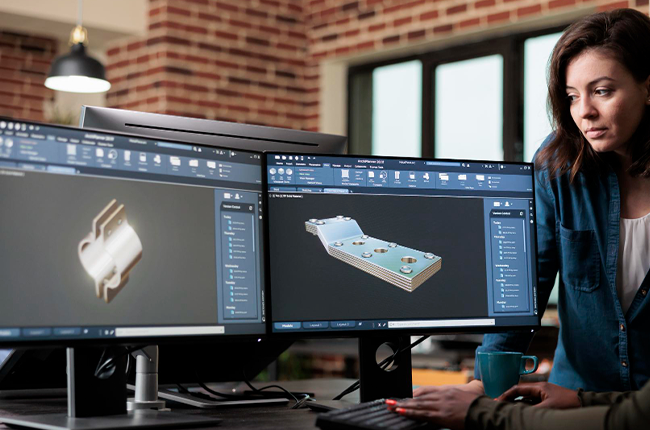

From CAD to CAM: Bridging Design and Manufacturing

The design and manufacturing sector has significantly benefited from the integration of CAD and CAM. The emergence of advanced technologies like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) has filled the gap between conceptualization and production, which helps create streamlined workflows. It is not confined only to efficient workflow but also saves time, improves accuracy, and drives innovation. Here the reader will learn about the fundamentals of CAD-CAM technologies their integration, and their transformative impact on modern industries.

What is CAM?

CAM is also known as Computer-Aided Manufacturing. This software and technology are used for the automated manufacturing process to control the manufacturing tools and equipment. Advanced manufacturing tools like CAM change digital designs into physical products by programmed processes like machining, milling, 3D printing and laser cutting.

The feature includes toolpath generation, simulation tool and Integration with CNC machines. All have these functionalities, such as the toolpath generation, which provides optimized machine routes. In the same way, the simulation tool works to detect potential errors before production. Similarly, integration with CNC machines helps to execute designs precisely. Some of the advanced manufacturing tools are Mastercam, Fusion 360 and Edgecam.

What is CAD?

CAD is known as Computer-Aided Design. CAD software helps engineers make precise drawings and 3D models of products, structures, and systems. It is the best for replacing traditional hand-drawn techniques with digital tools. The benefit is that it helps the designer visualise concepts and test feasibility.

A few features include 3D Modeling, Simulation Tools, design Libraries, and Collaboration tools. These tools help visualise the products and speed up the process, which is aligned with real-world conditions. Famous examples of CAD software are AutoCAD and Solidworks.

The Bridge Between CAD and CAM

The integration of CAD and CAM is critical when it comes to transforming modern manufacturing processes. The efficient integration of CAD-CAM technologies bridges the gap between conceptual designs and physical products. Here is the elaboration on how both integrations of CAD and CAM work together. Let's dive here: -

Design to Production Flow: CAD is used for creating detailed designs and 3D models, whereas CAM converts them into machine-readable instructions for precise manufacturing

Elimination of Manual Intervention: With the integration of CAD and CAM, manual steps, such as re-entering design data for manufacturing or interpreting design details, are eliminated.

Enhanced Data Accuracy: CAD designs can be changed into CAM, ensuring data integrity and eliminating errors during manual data entry.

Optimised Production Process: Real-time modifications in CAD are instantly reflected in CAM, improving efficiency and reducing costs without starting over.

Faster Time-to-Market: Seamless integration speeds up the process from concept to production, allowing quicker product launches.

Automated Manufacturing: CAD and CAM integration automates production with CNC machines, 3D printers, and robotics for greater precision and reduced waste.

Collaboration Across Teams: Integrated systems foster better collaboration between design and manufacturing teams, addressing feasibility issues early.

Applications of CAD-CAM in Modern Industries

After learning how CAD-to-CAM integration improves manufacturing efficiency, let's explore the industrial applications of CAD-CAM.

In the automotive industry, the integration of CAD and CAM is used to design complex vehicle parts and automated production lines.

In the aerospace sector, CAD and CAM are integrated to produce lightweight and high-precision components.

The integration of CAD and CAM in the healthcare sector develops prosthetics and surgical tools with unmatched precision.

Seamless CAD to CAM transition is used for intricate designs for smartphones and gadgets.

Helps in designing prefabricated components and modular homes.

Addressing Challenges in CAD-CAM Integration

CAD software for engineer's envelope with a few challenges when they use these technologies: -

Poor software compatibility between CAD and CAM tools.

Lack of training personnel to use advanced tools effectively.

More money is required for software, hardware, and training.

Mitigating issues in toolpaths during simulation stages.

What is the Future Implication?

Future trends in CAD-CAM are rapidly expanding, with many customised designs using AI, cloud computing, and more to come, which will help to make the design and manufacturing process smoother and more remotely accessible.

Final Thoughts

From conceptualisation to the final product, CAD and CAM have become indispensable tools in modern manufacturing. Their integration improves efficiency and opens doors to innovation and creativity across industries. As these technologies evolve, their potential to revolutionise manufacturing will grow, ensuring a future defined by precision, speed, and sustainability.