Exploring the Future of Machining Technology: Trends and Innovations

Machining technology is crucial in making many of the things we use every day. From cars and airplanes to tiny gadgets, machining shapes and refines materials into useful products. As we move into the future, machine technology is evolving rapidly. Let’s explore some of the exciting trends and innovations shaping this field.

Quantum Computing-Driven Machining

Quantum computing is set to revolutionize machining by 2100. Quantum computers, capable of processing vast amounts of data at unprecedented speeds, will optimize machining processes to an incredible degree. These computers will instantly solve complex problems, allowing for real-time adjustments and fine-tuning of machining operations.

This will result in perfect precision, minimal waste, and maximal efficiency, setting new standards in manufacturing quality and productivity.

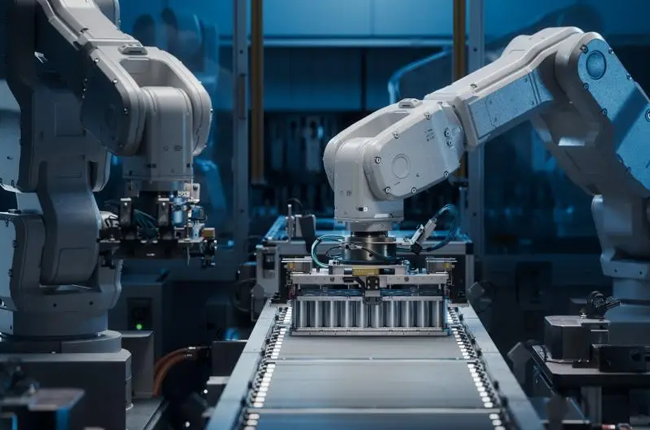

Autonomous Machining Systems

Fully autonomous machining systems will dominate the industry. These systems, equipped with advanced AI and machine learning, will operate without human intervention. They will self-repair, self-optimize, and continually learn from their operations to improve performance.

Autonomous machines will detect and correct errors on the fly, adapt to new materials, and adjust to varying production demands seamlessly, leading to unprecedented levels of efficiency and reliability.

Molecular Manufacturing

Molecular manufacturing will allow for the precise manipulation of atoms and molecules to create materials with superior properties. This technology will enable the construction of products atom by atom, resulting in materials that are incredibly strong, lightweight, and durable.

This will revolutionize industries such as aerospace, automotive, and healthcare, enabling the production of high-performance components and devices that were previously unimaginable.

Biological Machining

The future will see the integration of biological processes into machining technology, leading to the development of biological machining. Bioengineered organisms will be used to grow and form materials, creating organic and hybrid products.

This approach will be particularly useful in producing medical implants and biodegradable products. Biological machining will open new possibilities for sustainable manufacturing and innovative material design.

Nanobots in Machining

Nanotechnology will advance to the point where nanobots can perform machining tasks at the nanoscale. These tiny robots will construct intricate components for electronics, medical devices, and more, with extraordinary precision and speed.

Operating in swarms, nanobots will build structures atom by atom, enabling the creation of highly complex and miniaturized products. This technology will push the boundaries of what is possible in fields like nanomedicine and microelectronics.

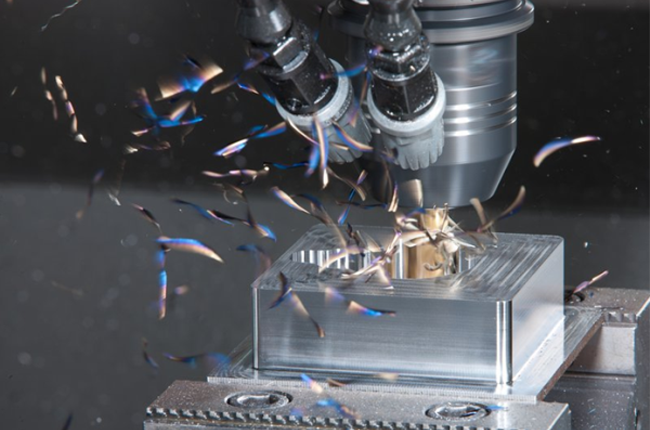

Hyper-Speed Machining

Hyper-speed machines will drastically reduce production times by 2100. Advanced materials and innovative cooling techniques will allow machines to operate at incredibly high speeds without sacrificing precision.

This will be particularly beneficial in industries requiring rapid production of high-precision components, such as aerospace, automotive, and electronics. Hyper-speed machining will lead to shorter lead times and increased production efficiency, meeting the growing demands of these sectors.

Augmented Reality (AR) Assisted Machining

Augmented Reality (AR) will become a staple in machine technology, overlaying digital information onto physical environments. AR will guide operators in real-time, providing visual instructions, highlighting critical areas, and displaying performance metrics.

This technology will enhance accuracy, reduce errors, and enable complex tasks to be performed with ease. Additionally, AR will facilitate remote collaboration, allowing experts to assist operators from anywhere in the world.

Zero-Waste Machining

Sustainability will be a key focus in machining technology, leading to zero-waste machining processes. Advanced recycling techniques will allow for the complete recovery and reuse of materials, producing no waste and minimizing environmental impact.

This approach will conserve natural resources and contribute to a more sustainable and eco-friendly manufacturing industry, aligning with global efforts to reduce waste and environmental degradation.

Self-Assembling Materials

Self-assembling materials will revolutionize manufacturing by 2100. These materials can assemble themselves into complex structures at the molecular level, eliminating the need for traditional machining processes.

This technology will be used in a wide range of applications, from electronics and medical devices to construction and aerospace, enabling the creation of intricate and highly functional products with unprecedented efficiency.

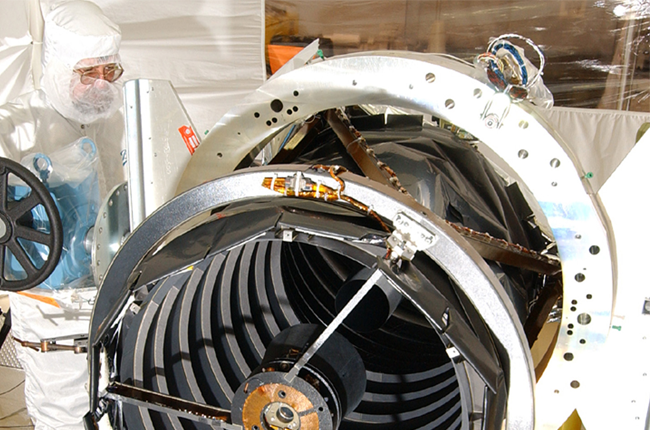

Space-Based Machining

As humanity expands into space, machine technology will be adapted for zero-gravity environments. Space-based machining will support the construction of components and structures necessary for space exploration and colonization.

New techniques will be developed to take advantage of the unique conditions in space, allowing for the construction of habitats, spacecraft, and other infrastructure required for long-term space missions and the establishment of colonies on other planets.

Final Thoughts!

The future of machine technology is bright and full of exciting possibilities. From automation and robotics to AI and nanotechnology, innovations are making machines faster, more precise, and more sustainable. As these trends continue to develop, we can expect even more impressive advancements in the years to come.

Machining technology is not just about making things; it’s about making things better, smarter, and more efficient. This progress will benefit many industries and, ultimately, our everyday lives.