Exploring Modular Design: Benefits and Applications in Manufacturing

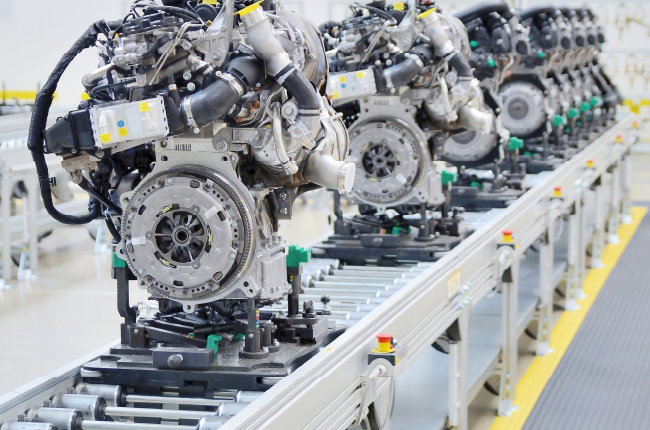

The modern industrial landscape is marked by intense competition. Companies must innovate faster, cut costs, and still meet customer demands for personalized products. One strategy that makes this possible is modular design manufacturing. This method breaks products into small, interchangeable modules. With this, manufacturers gain flexibility, improve efficiency, and speed up innovation. It’s not limited to one industry. From automotive to electronics, businesses are using modularity to streamline production and support mass customization. In this blog we come to know that modular design manufacturing is shaping the future of industries with real benefits and wide applications.

What is Modular Design in Manufacturing?

At its core, modular design manufacturing involves creating products from smaller, standardized units or modules that can be independently produced and assembled. Unlike traditional linear production methods, modular systems encourage adaptability.

For instance, in the automotive industry, one vehicle platform may support multiple car models. Similarly, in electronics, laptops and smartphones often rely on modular components for upgrades or replacements. This strategy highlights the growing importance of modular product architecture, where each component is designed for compatibility and interchangeability.

Key Benefits of Modular Design Manufacturing

The advantage of modular design includes:

Flexibility and Scalability

Manufacturers can easily add, upgrade, or replace components without redesigning the entire system. This adaptability supports faster innovation cycles.Cost Efficiency

Standardized modules reduce material waste, enable faster prototyping, and improve economies of scale.Mass Customization Modularity

One of the biggest advantages is the ability to create tailored products while maintaining efficiency. Customers enjoy personalized choices without driving up production costs.Sustainability

Since modules can be reused, recycled, or upgraded, modular design manufacturing naturally supports eco-friendly practices and circular economies.Speed to Market

Standardized processes and modular systems accelerate product development, reducing time-to-market for new designs.

Applications of Modular Product Architecture

The Modular product methods are used in various sectors, which include:

Automotive Industry

Leading manufacturers use modular platforms across multiple car models, saving billions in design and production costs.

Consumer Electronics

From laptops to modular smartphones, companies are using modular product architecture to improve repairability and extend product lifecycles.

Furniture Manufacturing

Brands like IKEA thrive on modularity, offering flexible, easy-to-assemble products designed for urban lifestyles.

Industrial Machinery

Factories increasingly rely on modular systems for configurable equipment, which allows them to meet diverse customer needs.

Construction and Prefabrication

In the construction sector, modular housing and prefabricated buildings are transforming how homes and offices are built.

Challenges and Considerations

While modular design manufacturing offers undeniable advantages, it does come with challenges:

Balancing standardization with innovation can be difficult.

Initial design and planning may require higher investment.

Supply chain coordination is crucial to ensure quality and consistency.

Manufacturers who overcome these hurdles can unlock enormous long-term benefits.

Future Trends in Modular Manufacturing

The future of modular design manufacturing is closely tied to Industry 4.0. AI-driven analytics, digital twins, and smart factories will make modularity even more powerful.

As demand for sustainable and flexible production grows, mass customization modularity will dominate markets, giving consumers more choices while reducing environmental impact. Additionally, automation and robotics will strengthen modular assembly lines, making them more efficient and scalable.

Final Words

From cost savings to personalization, modular design manufacturing is reshaping industries across the globe. Its adaptability, efficiency, and sustainability make it a cornerstone of modern production strategies. By embracing modularity, businesses can accelerate innovation and remain competitive in a rapidly changing marketplace.

Whether through modular product architecture in electronics or mass customization modularity in consumer goods, this design philosophy is the future of manufacturing.