Evolution of Metrology: Manual to Automated Systems

The Evolution of Metrology from Manual to Automated Systems has transformed the way industries measure accuracy and maintain quality. From hand-held tools to smart inspection machines, metrology has come a long way. It now plays a critical role in sectors like manufacturing, aerospace, automotive, and healthcare. Earlier, skilled workers handled every measurement with manual instruments. Today, advanced machines perform inspections with speed, consistency, and precision. This transformation has reduced human error, improved product reliability, and increased production efficiency. In this blog, you will understand how metrology evolved, the key differences between manual and automated systems, the major technological advancements, and what the future holds for precision measurement.

Understanding Metrology and Its Transformation Over Time

The Evolution of Metrology from Manual to Automated Systems has reshaped how industries measure, inspect, and control quality. Metrology plays a vital role in manufacturing, aerospace, automotive, and healthcare. Every product depends on accurate measurement. In the past, workers relied on hand tools and personal skill. Today, machines handle most inspection tasks with speed and accuracy. This shift has improved product quality and reduced human error on a massive scale.

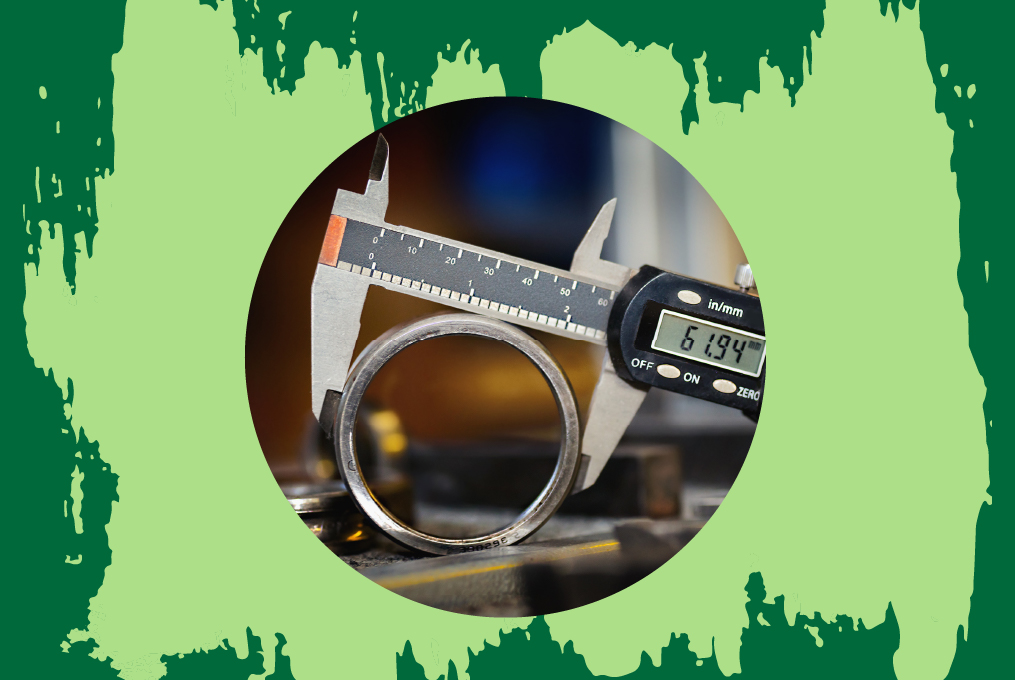

Early Days of Manual Metrology Systems

In the beginning, all measurements depended on manual tools. Engineers used vernier calipers, micrometers, height gauges, and dial indicators. These tools required skill and constant focus. Even a small mistake could lead to faulty parts. Temperature, pressure, and human fatigue often affected results. Still, these tools laid the foundation for modern measurement. The early phase of the Evolution of Metrology from Manual to Automated Systems depended heavily on human experience and patience.

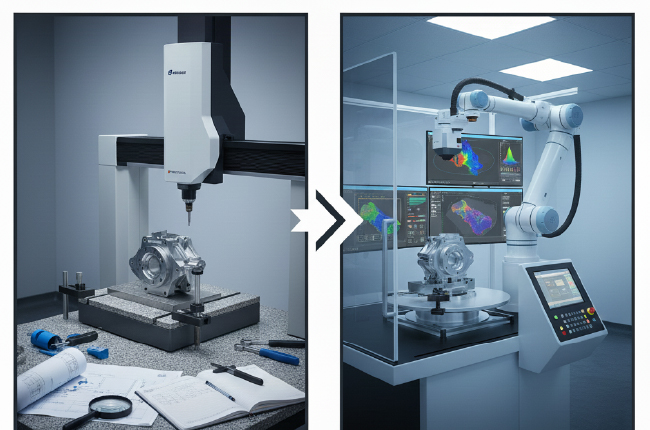

Transition Phase: Semi-Automated Metrology

As industries grew, the need for faster and more reliable inspection increased. This led to digital measuring tools and the first Coordinate Measuring Machines (CMMs). Operators now relied on software to assist with measurements. Digital displays reduced reading errors. Data became easier to store and analyze. This stage acted as a bridge in the Evolution of Metrology from Manual to Automated Systems, combining human control with machine precision.

Rise of Automated Metrology Systems

Automation changed everything. Modern systems now use robotic arms, optical scanners, and laser-based inspection. These machines capture millions of data points within seconds. Operators only program the system and monitor the process. Vision systems check surface defects with extreme accuracy. This advanced stage of the Evolution of Metrology from Manual to Automated Systems allows factories to inspect 100% of production without slowing output.

Manual vs Automated Metrology Systems

The comparison between Manual vs Automated Metrology Systems highlights the true value of automation. Manual methods depend on human skill and time. Automated systems deliver speed, repeatability, and accuracy. Manual inspection suits small workshops and low-volume jobs. Automated inspection supports mass production and strict quality standards. When companies analyze Manual vs Automated Metrology Systems, they often choose automation for long-term growth.

Key Advancements of Metrology Technology

The Advancement of Metrology Technology has accelerated with Industry 4.0. Smart sensors, cloud connectivity, and digital twins now dominate inspection systems. Machines share real-time data across departments. Software predicts quality issues before defects appear. The second major Advancement of Metrology Technology involves artificial intelligence. AI systems now detect patterns that humans might miss. These innovations support faster decisions and stronger quality control.

Benefits of Automated Metrology in Manufacturing

Automation brings powerful benefits to modern manufacturing. It improves accuracy and keeps results consistent across batches. It reduces scrap, rework, and downtime. Automated systems work nonstop without fatigue. They also protect workers from hazardous environments. In the long run, the Evolution of Metrology from Manual to Automated Systems helps companies cut costs and increase profit margins.

Future of Metrology Systems

The future promises even smarter solutions. AI-driven inspection will become standard. Fully autonomous systems will handle inspection without human input. Predictive quality control will prevent defects before production begins. Cloud platforms will connect machines across multiple factories. The next phase of the Evolution of Metrology from Manual to Automated Systems will focus on self-learning systems and zero-defect manufacturing.

Conclusion

The journey of measurement science reflects continuous innovation and improvement. From simple hand tools to intelligent inspection systems, the transformation remains remarkable. The Evolution of Metrology from Manual to Automated Systems continues to shape how industries ensure quality, safety, and efficiency. Automation no longer supports manufacturing—it leads it. Companies that adopt advanced metrology tools today stay ahead in tomorrow’s competitive market.