Enhancing Product Quality through Advanced Machining Techniques

Now a days, people expect high-quality products. Whether it's a car, a phone, or a piece of furniture, everyone wants items that work well and last a long time. One way to make sure products meet these high standards is through advanced machining techniques. These techniques are methods used to shape and create parts with great precision. Let's explore how these techniques help improve product quality.

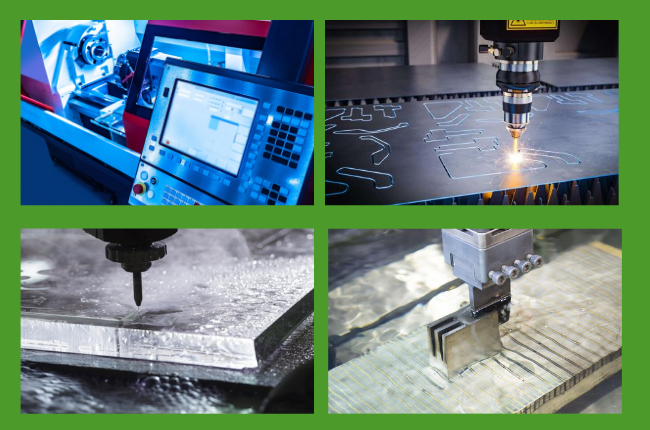

Types of Advanced Machining Techniques

There are several advanced machining techniques that manufacturers use to create high-quality products. Here are some of the most important ones:

CNC Machining (Computer Numerical Control)

CNC machining uses computers to control machine tools. This method allows for very precise cuts and shapes. The computer follows a set of instructions (a program) to cut the material exactly as needed. This precision reduces errors and makes sure each part is made to exact specifications.

Laser Cutting

Laser cutting uses a high-powered laser to cut materials. The laser can cut through metals, plastics, and even wood with great accuracy. This technique is perfect for making intricate designs and detailed parts. It also leaves a clean edge, which reduces the need for further finishing.

Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water, sometimes mixed with an abrasive material, to cut through materials. This method is very versatile and can cut through almost any material, including metals, stone, and glass. It is also a cold cutting process, meaning it does not generate heat that could damage the material.

Electrical Discharge Machining (EDM)

EDM uses electrical sparks to shape metal. The process involves making sparks between a metal workpiece and an electrode. These sparks remove tiny bits of metal, shaping the workpiece. EDM is great for making very precise parts and works well with hard metals that are difficult to machine with traditional methods.

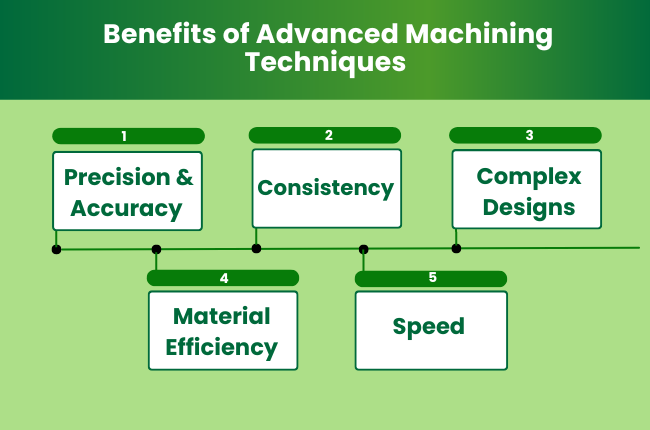

Benefits of Advanced Machining Techniques

Using advanced machining techniques provides several benefits that enhance product quality. Here are some key advantages:

Precision and Accuracy

Advanced machining techniques allow for incredibly precise cuts and shapes. This precision ensures that each part fits perfectly with others, reducing the risk of defects and improving the overall quality of the product.

Consistency

With computer-controlled methods like CNC machining, manufacturers can produce parts that are consistent in quality. Every part made using the same program will be identical, which is crucial for products that require interchangeable parts.

Complex Designs

Techniques like laser cutting and EDM make it possible to create complex and intricate designs that would be impossible with traditional methods. This allows for more innovation and creativity in product design.

Material Efficiency

Advanced machining techniques often result in less waste. For example, waterjet cutting uses nearly all the material, with very little leftover. This efficiency not only saves materials but also reduces costs.

Speed

These advanced techniques can produce parts quickly. CNC machines and lasers can work continuously without needing breaks, which speeds up the manufacturing process and allows companies to meet high demand.

Applications in Various Industries

Advanced machining techniques are used in a wide range of industries. Here are a few examples:

Automotive Industry: Car manufacturers use CNC machining and laser cutting to make precise engine parts, body panels, and interior components. This precision ensures that vehicles are safe, reliable, and efficient.

Aerospace Industry: The aerospace industry requires parts that can withstand extreme conditions. Techniques like EDM are used to create parts for airplanes and spacecraft that must be both lightweight and incredibly strong.

Medical Industry: In the medical field, advanced machining is used to make surgical instruments and implants. These parts must be made with extreme precision to ensure patient safety and effectiveness.

Electronics Industry: Electronics require very small and precise components. Laser cutting and CNC machining are used to make circuit boards and other parts that need to fit together perfectly.

Final Thoughts!

Advanced machining techniques play a crucial role in enhancing product quality. They provide precision, consistency, and efficiency, allowing manufacturers to create high-quality products that meet the demands of today's consumers.

As technology continues to grow, these machining techniques will only become more important in producing the products we use every day.