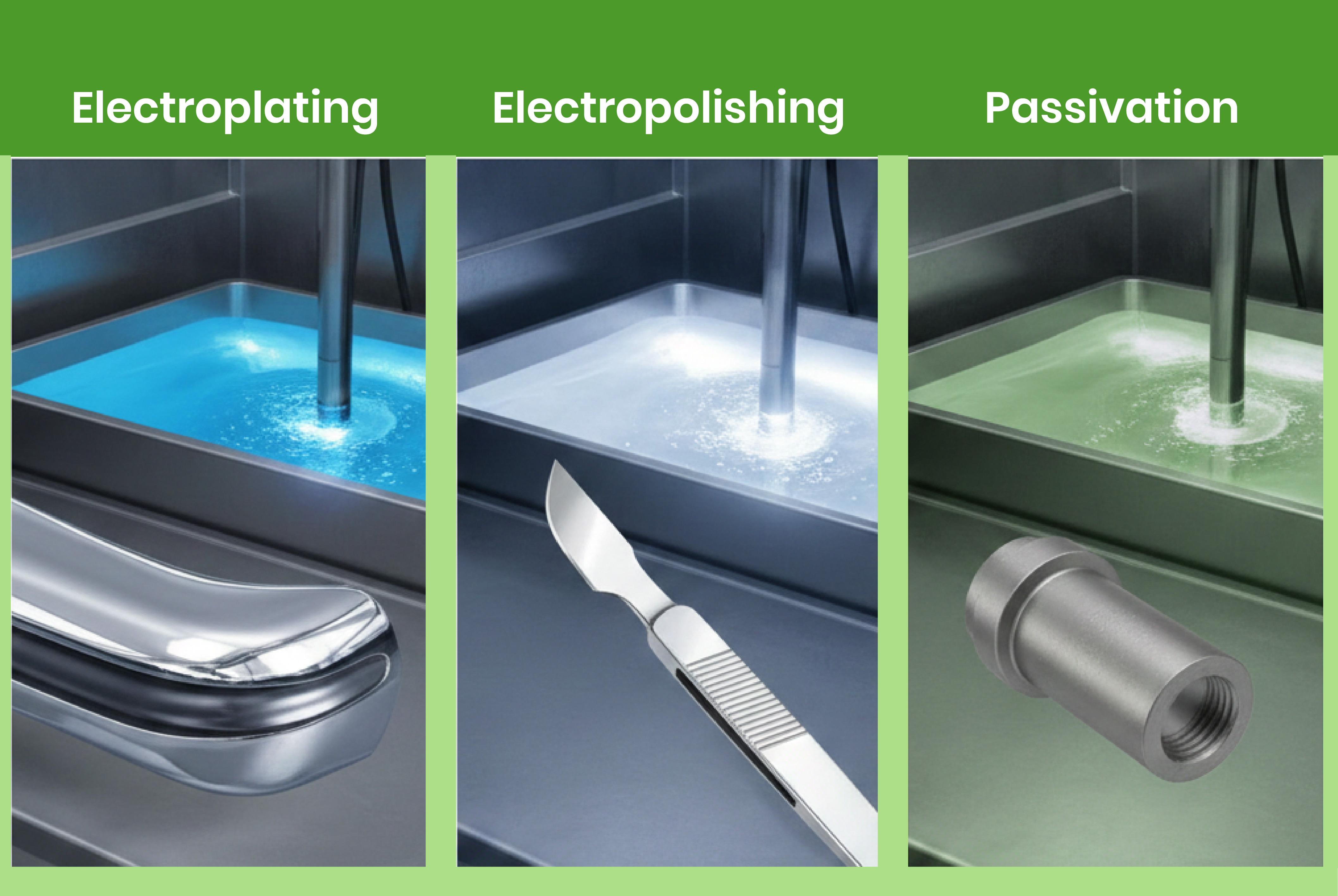

Electroplating vs Electropolishing vs Passivation: Complete Guide

When it comes to protecting metal parts and improving their performance, choosing the right finishing method matters. Electroplating vs Electropolishing vs Passivation is a common comparison in industries like automotive, medical, food processing, and manufacturing. Each process serves a unique purpose, yet many people confuse them. This guide breaks down the Difference between electroplating, electropolishing, and passivation in a simple way. You will also understand how these Surface finishing processes for metal impact durability, appearance, and corrosion resistance.

What Is Electroplating?

Electroplating adds a thin metal layer on the surface of another metal using electric current. The coating improves strength, corrosion resistance, and visual appeal.

Common coating metals include:

Nickel

Chrome

Zinc

Gold

Manufacturers use this method to prevent rust, reduce friction, and enhance product life. You often see electroplated parts in automobiles, hardware tools, electronics, and decorative items.

In the Electroplating vs Electropolishing vs Passivation debate, electroplating stands out because it adds material instead of removing or chemically treating the surface.

What Is Electropolishing?

Electropolishing removes a thin outer layer of metal using an electrochemical process. It smooths the surface at a microscopic level and improves cleanliness.

Key benefits include:

Ultra-smooth surface finish

Improved corrosion resistance

Enhanced appearance

Better fatigue life

Industries like medical devices, food equipment, and pharmaceuticals rely heavily on electropolishing. Unlike electroplating, it does not add any coating.

In any serious discussion of Electroplating vs Electropolishing vs Passivation, this process is known for precision and cleanliness.

What Is Passivation?

Passivation is a chemical treatment used mainly on stainless steel. It removes free iron from the surface and strengthens the natural oxide layer.

Its main purpose is corrosion protection, not appearance. The process does not change dimensions or add a coating.

Typical industries using passivation include:

Medical equipment

Aerospace

Food processing

Marine applications

In the Electroplating vs Electropolishing vs Passivation comparison, passivation wins when corrosion protection is the only goal.

Key Difference Between All Three Processes

Understanding the Difference between electroplating, electropolishing, and passivation becomes easy when you focus on what each process does.

Electroplating: Adds a protective metal layer

Electropolishing: Removes surface material for smoothness

Passivation: Chemically enhances corrosion resistance

These Surface finishing processes for metal also vary in cost, application time, and maintenance needs. Some improve looks, while others focus purely on protection.

When industries compare Electroplating vs Electropolishing vs Passivation, the choice always depends on the final product goal.

Application-Based Comparison

Each process has a specific use case:

Electroplating works best for parts that need decorative finish and wear protection.

Electropolishing suits components that require hygiene, low friction, and precision.

Passivation fits products where corrosion control is critical without altering dimensions.

In manufacturing, engineers often combine these Surface finishing processes for metal for better long-term results.

The real strength of the Electroplating vs Electropolishing vs Passivation comparison lies in selecting the right process for the right environment.

Cost, Durability, and Maintenance

Electroplating tends to cost more due to added metal and multi-step processing. However, it offers superior wear protection.

Electropolishing falls in the mid-range. It improves product life and reduces future maintenance.

Passivation costs the least. It provides essential corrosion protection with minimal upkeep.

From a budget perspective, the Electroplating vs Electropolishing vs Passivation decision depends on long-term performance rather than short-term cost.

Which Process Should You Choose?

You should choose based on:

Product usage

Exposure to moisture or chemicals

Appearance needs

Hygiene requirements

Budget

If your goal is shine and surface strength, electroplating works best. If you need cleanliness and smoothness, electropolishing is ideal. If corrosion prevention is enough, passivation fits well.

This is why engineers carefully study Electroplating vs Electropolishing vs Passivation before finalising any production method.

Final Thoughts

Choosing the right surface treatment improves product life, performance, and safety. The debate around Electroplating vs Electropolishing vs Passivation is not about which is better overall. It is about which is better for your application.

By understanding the Difference between electroplating, electropolishing, and passivation, you can make smarter manufacturing decisions. These proven Surface finishing processes for metal continue to shape modern industrial production with reliability and precision.