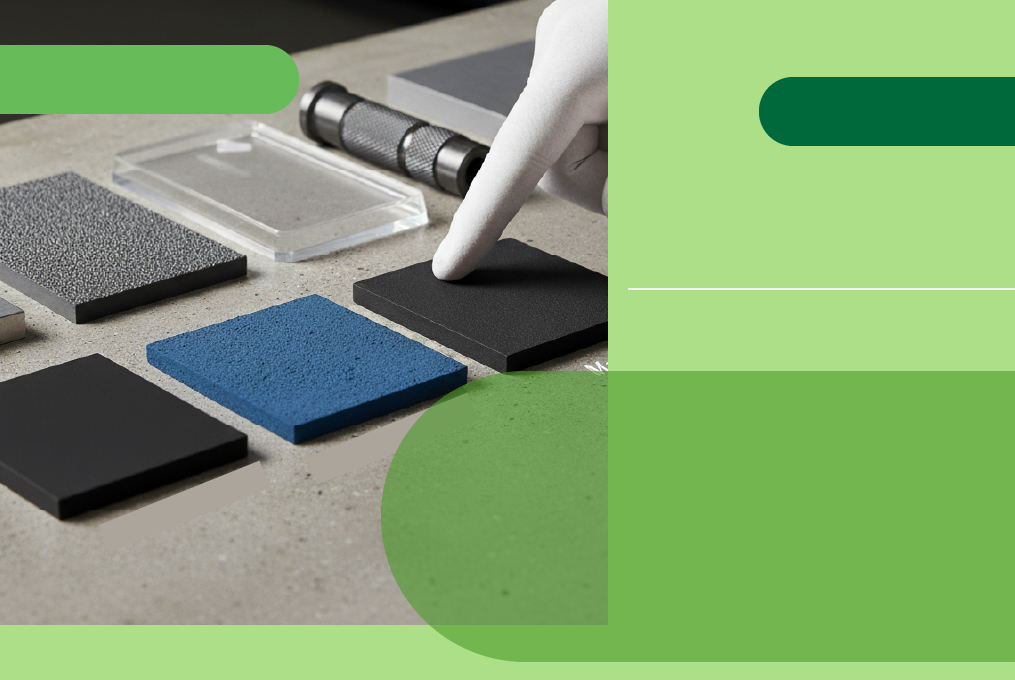

Choosing the Right Surface Finish: Anodizing, Powder Coating, or Zinc Plating?

When protecting metal parts, selecting the right coating is crucial. Surface finish options not only enhance appearance but also improve durability and corrosion resistance. Anodizing, powder coating, and zinc plating are three popular methods. Each has its strengths and understanding them helps you make the best choice for your project.

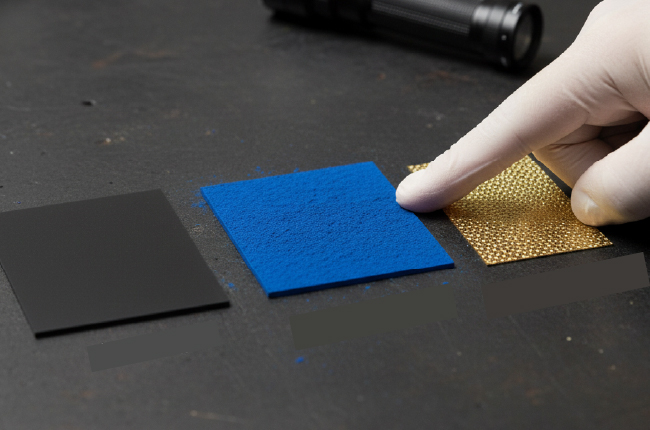

What is Anodizing?

Anodizing is an electrochemical process that thickens the natural oxide layer on metals, usually aluminium. This creates a hard, corrosion-resistant surface. The finish can be clear, colored, or even textured.

Benefits of anodizing:

Long-lasting corrosion protection.

Improved surface hardness.

Attractive colour options that don’t fade easily.

You’ll find anodized metals in electronics, aerospace, and architectural elements. When comparing anodizing vs powder coating, anodizing wins for wear resistance and a natural metal look.

What is Powder Coating?

Powder coating involves spraying a dry powder onto metal and curing it with heat. This creates a smooth, durable, and colourful finish. Powder coating resists scratches, chemicals, and UV damage better than regular paint.

Advantages of powder coating:

Wide range of colours and textures.

Strong resistance to wear and corrosion.

Environmentally friendly with no solvents.

Powder coating is widely used in furniture, automotive parts, and appliances. Compared to anodizing, it offers more colour flexibility but slightly less surface hardness.

What is Zinc Plating?

Zinc plating involves applying a thin layer of zinc to metal surfaces to prevent rust. It’s cost-effective and versatile, with finishes like clear, yellow, or black for different applications.

Zinc plating benefits:

Excellent rust prevention.

Affordable for large-scale production.

Suitable for industrial, automotive, and household items.

Zinc plating works well for functional components where corrosion resistance is important. Its versatility makes it one of the most widely used surface finish options.

Comparing Surface Finishes

When choosing among surface finish options, consider:

Durability: Anodizing and powder coating offer strong resistance, while zinc plating provides good protection at a lower cost.

Cost: Zinc plating is the most economical, followed by powder coating, then anodizing.

Appearance: Powder coating allows for vibrant colours, anodizing gives a natural metallic look, and zinc plating is more utilitarian.

Maintenance: All three finishes require minimal care, but anodized surfaces are easiest to maintain.

Choosing the Right Finish for Your Project

Selecting the right surface finish depends on several factors. Evaluating the environment, purpose, and budget helps you make the best choice. Here’s a detailed guide:

Consider the Environment

Outdoor Exposure: Metals exposed to rain, humidity, or sunlight need strong corrosion resistance. Anodizing and powder coating are excellent for weather resistance, while zinc plating provides reliable rust prevention for industrial applications.

Harsh Chemicals or Salty Air: For coastal areas or chemical plants, anodized surfaces resist corrosion better than standard coatings. Powder coating with specialized formulations also works well in chemical environments.

Temperature Conditions: Anodized coatings withstand high temperatures better than powder coating, which may discolor or degrade under extreme heat.

2. Determine the Purpose

Aesthetic Appeal: If the look of the metal is important, anodizing offers a sleek, metallic finish, while powder coating provides vibrant colours and textures. Zinc plating is more functional and less about aesthetics.

Wear and Tear: High-contact or moving parts benefit from anodizing, which increases surface hardness. Powder coating provides moderate protection against scratches and dents, while zinc plating protects against rust but is softer.

Industrial vs. Consumer Use: Functional components like fasteners, brackets, or machinery parts often rely on zinc plating benefits, while consumer-facing products such as electronics, furniture, or decorative items benefit from anodizing or powder coating.

Factor in Budget

Cost Efficiency: Zinc plating is the most economical surface finish option for large-scale production. Powder coating is moderately priced, offering good durability and aesthetics. Anodizing is typically the most expensive due to its specialized process.

Long-Term Value: While anodizing and powder coating cost more upfront, their durability and low maintenance often save money in the long run. Zinc plating may need more frequent replacement in high-wear conditions.

3. Maintenance and Longevity

Ease of Cleaning: Powder-coated and anodized surfaces are easy to clean and maintain without harsh chemicals. Zinc-plated surfaces may require occasional protective treatments to prevent oxidation.

Lifespan: Anodizing generally lasts the longest under heavy use and environmental exposure. Powder coating offers strong durability but may chip under extreme stress. Zinc plating provides adequate protection but is best suited for functional, less visible parts.

Final Thoughts

Choosing the right surface finish affects both durability and appearance. Anodizing offers wear resistance and a sleek look; powder coating provides vibrant colours and protection, and zinc plating delivers cost-effective rust prevention.

Consider the environment, purpose, and budget to pick up the finish that ensures long-lasting performance, low maintenance, and a professional appearance for your metal parts.