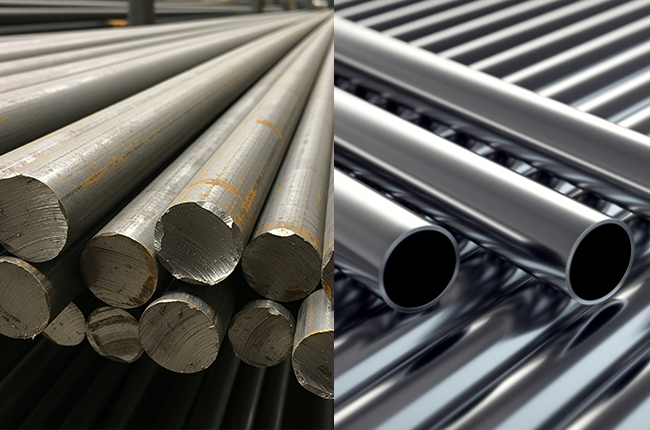

Carbon vs. Stainless Steel: Pros and Cons for Different Applications

When it comes to choosing the right type of steel for a project, two of the most common options are carbon steel and stainless steel. Both have unique qualities that make them suitable for a wide range of applications, from construction and manufacturing to kitchen tools and appliances. But how do you decide which one is best for your specific needs? Let’s explore the pros and cons of carbon steel and stainless steel in simple terms to help you make an informed decision.

What is Carbon Steel?

Carbon steel is a type of steel that mainly contains iron and carbon. It’s known for its strength and hardness, which makes it a popular choice for industrial applications. There are three types of carbon steel: low carbon steel, medium carbon steel, and high carbon steel, each varying in the amount of carbon content.

Low Carbon Steel: This type has the least amount of carbon, making it more flexible and easier to work with.

Medium Carbon Steel: It has a bit more carbon, which adds strength, but it can still be shaped or welded.

High Carbon Steel: This is the hardest and strongest of the three, but it can also be brittle and more difficult to work with.

What is Stainless Steel?

Stainless steel is a type of steel that contains iron, carbon, and at least 10.5% chromium, which gives it the ability to resist rust and corrosion. It’s commonly used in industries like food processing, healthcare, and construction because of its shiny appearance and durability.

There are different types of stainless steel, but they all have the common feature of being resistant to moisture and other environmental factors that could cause rust or corrosion.

Pros and Cons of Carbon Steel

Pros of Carbon Steel:

Strong and Durable: Carbon steel is incredibly strong, especially when compared to other types of steel. This makes it ideal for construction, tools, and heavy machinery.

Cost-Effective: Carbon steel is generally less expensive than stainless steel. If you're working on a budget, carbon steel might be the better option.

Variety of Uses: It can be used in a wide range of applications, from bridges and buildings to automotive parts and even kitchen knives.

Easier to Shape: Low carbon steel is easier to weld and form into different shapes, making it versatile for various projects.

Cons of Carbon Steel:

Prone to Rust: One of the biggest downsides of carbon steel is that it rusts when exposed to moisture and air. It needs to be coated or painted to prevent rusting.

Less Aesthetic Appeal: Carbon steel doesn't have the shiny, polished look that stainless steel has. This may not be a problem for industrial use, but it might not be the best choice for items that are meant to be decorative.

Can Be Brittle: High carbon steel, while very strong, can be brittle and may crack or break if put under too much stress.

Pros and Cons of Stainless Steel

Pros of Stainless Steel:

Rust and Corrosion Resistant: The chromium in stainless steel forms a protective layer on the surface that prevents rust. This makes it perfect for applications where the material will be exposed to moisture, like in kitchens or medical equipment.

Long-Lasting: Because it doesn’t rust or corrode easily, stainless steel tends to have a longer lifespan than carbon steel.

Attractive Finish: Stainless steel has a sleek, shiny appearance that makes it popular for items like appliances, cutlery, and furniture.

Hygienic: It’s easy to clean and doesn’t react with food, making it a preferred choice in the food and medical industries.

Cons of Stainless Steel:

More Expensive: Stainless steel tends to cost more than carbon steel, which can make it less appealing for large-scale projects where cost is a major factor.

Difficult to Work With: Stainless steel is harder to weld and shape than carbon steel. This can increase production time and costs for certain projects.

Heavier: Stainless steel is generally heavier than carbon steel, which might not be ideal for applications where weight is a concern, like in the automotive or aerospace industries.

Which One Should You Choose?

The choice between carbon steel and stainless steel depends largely on what you need the material for. Here are a few factors to consider:

If you need strength and durability for heavy-duty industrial use, carbon steel might be your best option. Its high strength makes it ideal for construction, machinery, and tools. Just keep in mind that you'll need to take measures to protect it from rusting.

If you’re working in environments where rust and corrosion are concerns, stainless steel is the way to go. It’s perfect for kitchens, hospitals, and outdoor use where the material will be exposed to water or humidity.

For projects where appearance matters, stainless steel has a clear advantage. Its polished, shiny look makes it a favorite for items like kitchen appliances, decorative pieces, and furniture.

If budget is a concern, carbon steel will usually be the more affordable option. However, you’ll need to consider the long-term costs of maintenance, especially in environments where rust could be an issue.

Final Thoughts!

In the debate of carbon vs. stainless steel, there’s no one-size-fits-all answer. Each type of steel has its strengths and weaknesses, and the best choice depends on your specific needs. Carbon steel is strong, affordable, and versatile, but it requires more maintenance to prevent rust. Stainless steel is resistant to rust and corrosion, long-lasting, and has an attractive appearance, but it’s more expensive and harder to work with.

Understanding the pros and cons of each can help you make the best choice for your project, whether it’s building a bridge or designing a set of kitchen knives.