5 Tips for Your Next Custom Perforated Sheet Metal Project

If you’re planning to work on a custom perforated sheet metal project, you’re in for a unique and exciting experience. Perforated sheet metal is incredibly versatile and can be used in everything from architectural designs to industrial applications. However, like any custom project, it comes with its own set of challenges and considerations. Whether you’re a beginner or have some experience, these five tips will help you get the most out of your next project.

Choose the Right Material

The first step in any perforated sheet metal project is selecting the right material. There are many options out there, and the material you choose will impact the durability, appearance, and performance of the final product.

Steel is strong and durable, making it a good option for industrial or heavy-duty applications.

Aluminum is lightweight and corrosion-resistant, perfect for outdoor projects or areas exposed to moisture.

Stainless steel offers both strength and a clean, polished look, ideal for decorative or architectural use.

Copper or brass can give a beautiful, unique appearance but can be more expensive.

Think about the environment your sheet metal will be exposed to. For example, if it's going to be outside, you want something that resists rust, like aluminum or stainless steel.

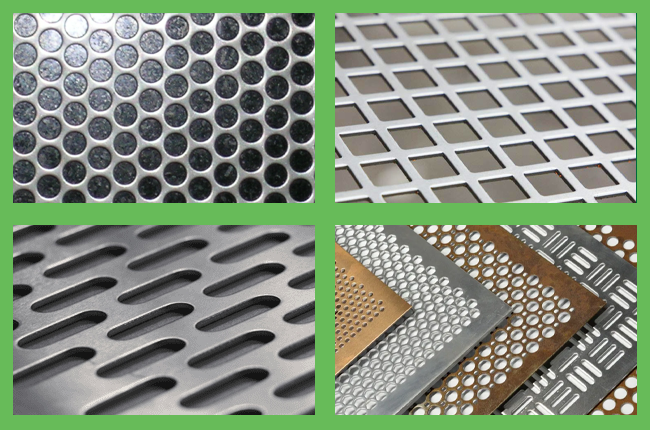

Understand the Perforation Patterns

Perforation patterns may seem like a small detail, but they can dramatically change the look and functionality of your sheet metal. There are different kinds of patterns, and each serves a purpose.

Round holes are the most common and versatile, used in everything from ventilation to decorative features.

Square holes give a more modern, clean look, often used in design projects.

Slotted holes are excellent for drainage or airflow, used in industrial or outdoor settings.

Custom shapes like hexagons, triangles, or stars can add an artistic touch and make your project stand out.

It’s essential to think about both the aesthetic and practical sides of your perforation pattern. For example, larger holes provide more ventilation or drainage but might weaken the sheet. Smaller holes, on the other hand, offer more strength but less airflow or visibility.

Plan for the Open Area Percentage

When designing a custom perforated sheet, the open area percentage refers to the amount of space taken up by the holes compared to the solid parts of the sheet. This is an important factor that affects both the strength and functionality of your metal.

For example, if you need something for soundproofing, a higher open area percentage will allow more sound to pass through. On the flip side, if you’re using perforated metal for a structural purpose, you’ll want to keep the open area percentage lower, so the sheet stays strong.

In general:

10-20% open area: Stronger and more durable but allows less airflow.

40-60% open area: More airflow or visibility, but weaker.

Work with your supplier to make sure your open area percentage is right for your project’s needs.

Consider the Finishing Process

Finishing might seem like an afterthought, but it’s essential for ensuring your custom perforated sheet metal project looks good and lasts long. Finishing adds both protection and beauty to the sheet metal.

Powder coating provides a smooth, durable finish and comes in a variety of colors.

Anodizing is perfect for aluminum and gives the metal a protective layer, making it more resistant to corrosion and wear.

Polishing can give your sheet metal a reflective, shiny surface, which is great for decorative or architectural use.

Galvanizing adds a layer of zinc to steel, protecting it from rust, especially for outdoor or industrial projects.

Don’t skip this step—choosing the right finish will not only enhance the appearance but also extend the life of your project.

Work with a Reputable Supplier

Lastly, it’s important to work with a supplier who understands your needs and can provide high-quality materials and services. A good supplier will offer you a variety of customization options, from material and pattern choices to finishing processes. They can also provide advice on how to best design your project for your specific needs.

When choosing a supplier, look for:

Experience in the industry: A company that has worked on custom perforated metal projects similar to yours.

Flexibility: A supplier who can accommodate custom designs, no matter how unique.

Quality assurance: Ask about the quality control measures they have in place to ensure your project meets your standards.

Timely delivery: Especially for larger projects, make sure the supplier can meet your deadlines without sacrificing quality.

Final Thoughts!

Custom perforated sheet metal is a fantastic option for projects where you need a combination of form and function. By choosing the right material, understanding your perforation pattern and open area percentage, considering the finishing process, and working with a reliable supplier, you can ensure that your next custom project is a success.

Whether you’re building something purely decorative or need a heavy-duty, functional solution, these tips will guide you in the right direction.

Now, you're all set to get started on your custom perforated sheet metal project. Have fun, and don’t be afraid to get creative!